Antibiotic sustained release system building method of medical titanium alloy implant surface

A construction method and implant technology, which is applied in the field of preparation of medical anti-infection metal implant materials, can solve problems such as coating peeling off, unresolved effective combination of coating and metal materials, unfavorable clinical use, etc., and achieve stable combination The effect of strength, improving physical adsorption and chemical bonding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

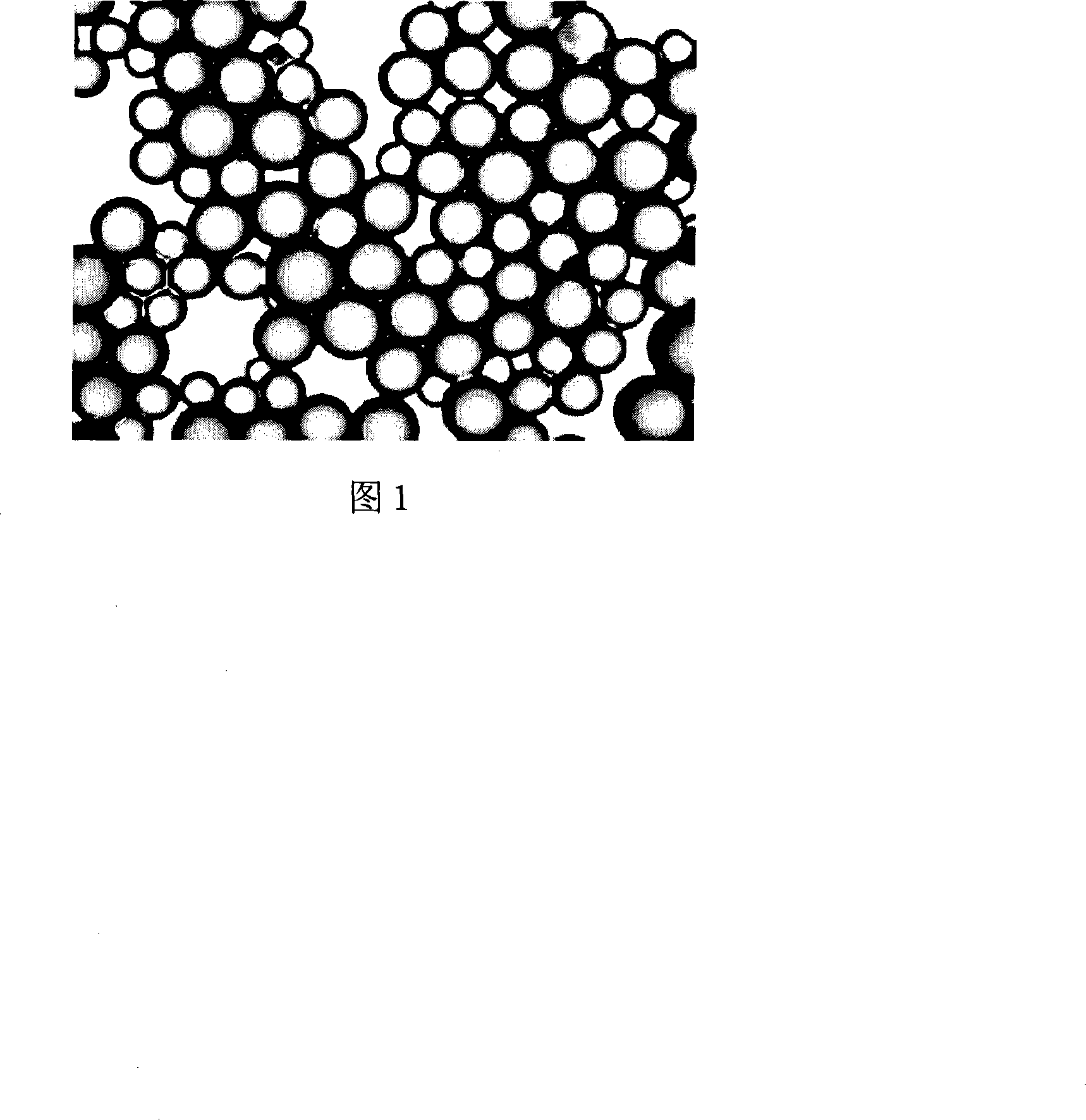

[0015] 1) Preparation of microporous layer morphology on the surface of medical titanium alloy implants:

[0016] First, mix titanium beads with a diameter of 0.2-0.3mm with the additive urea, in which titanium beads or titanium powder account for 40% of the mass of the mixture, and then apply the mixture on the surface of the prosthesis with a coating thickness of 0.5-1.0mm , and put it in a vacuum furnace for sintering at 1000°C for 3 hours to sinter the titanium beads together and sinter with the prosthesis at the same time; use high temperature to volatilize the additives naturally, and the temperature close to the melting point will sinter the beads to each other , while sintering it with the prosthesis. The sintering of titanium beads is generally double-layer or three-layer. After sintering, the size of the three rows of beads is 0.6-0.9mm, the pore size is 100-300μm, and the average porosity is 30-60%;

[0017] 2) Modification of surface chemical properties of medical...

Embodiment 2

[0022] 1) Preparation of microporous layer morphology on the surface of medical titanium alloy implants:

[0023] First, mix titanium powder with a diameter of 0.2-0.3mm and additive magnesium powder, in which titanium beads or titanium powder account for 60% of the mass of the mixture, and then coat the mixture on the surface of the prosthesis with a coating thickness of 0.5-1.0mm , and put it in a vacuum furnace for sintering at 1100°C for 2 hours to sinter the titanium beads together and sinter with the prosthesis at the same time;

[0024] 2) Modification of surface chemical properties of medical titanium alloy implants

[0025] After the medical titanium alloy implant obtained in step 1 is ultrasonically cleaned, it is immersed in a 30% hydrogen peroxide solution, and the temperature is controlled at 67 ° C. After keeping it for 20 hours, it is taken out and cleaned with acetone solution. The medical titanium alloy implant cleaned with acetone solution The alloy implant wa...

Embodiment 3

[0029] 1) Preparation of microporous layer morphology on the surface of medical titanium alloy implants:

[0030] Firstly, titanium beads with a diameter of 0.2-0.3mm are mixed with the additive methylcellulose, wherein titanium beads or titanium powder account for 30% of the mass of the mixture, and then the mixture is coated on the surface of the prosthesis with a coating thickness of 0.5 -1.0mm, and put it in a vacuum furnace for sintering at 1050°C for 2.5 hours to sinter the titanium beads together and sinter with the prosthesis at the same time;

[0031] 2) Modification of surface chemical properties of medical titanium alloy implants

[0032] After the medical titanium alloy implant obtained in step 1 is ultrasonically cleaned, it is immersed in a 30% hydrogen peroxide solution, the temperature is controlled at 73°C, kept for 16 hours, taken out, cleaned with acetone solution, and the medical titanium alloy implant cleaned with acetone solution The alloy implant was pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com