Method for extracting chitin and chitin thereof

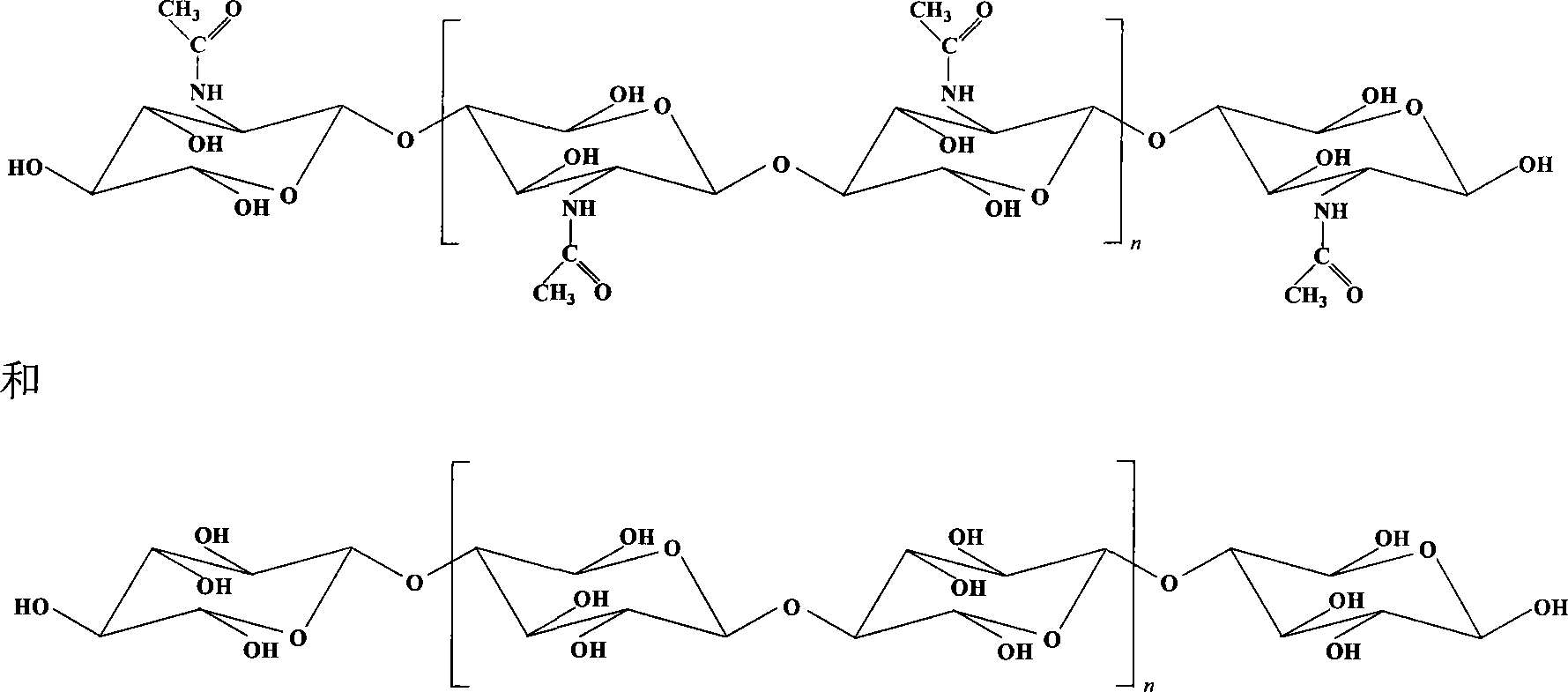

A technology of chitin and crude products, which is applied in the field of extraction of organic polymer compounds, can solve the problems of not being used in any way, and achieve the effects of improving comprehensive utilization value, high yield, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

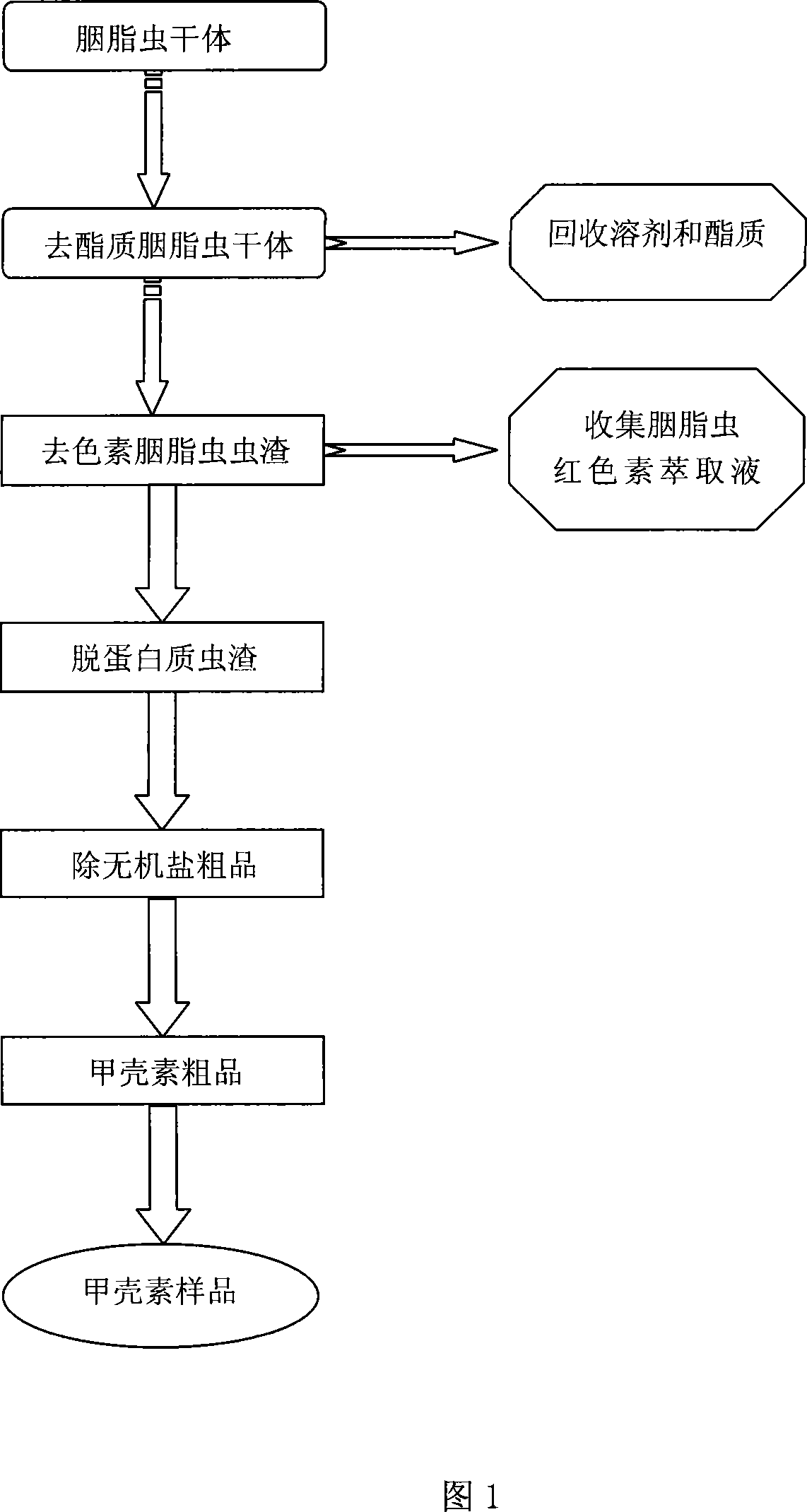

Method used

Image

Examples

Embodiment 1

[0033] Follow the steps below to extract chitin from cochineal slag:

[0034] 1) Remove protein

[0035] Take 50g of cochineal insect residue (dry weight), add 200mL of sodium hydroxide solution with a concentration of 1.0mol / L, heat and stir to mix evenly, heat to 80°C, and react for 1 hour, and filter the reaction solution with a 200-mesh filter , the resulting filtrate is rinsed with an appropriate amount of distilled water until the rinsed distilled water is neutral.

[0036] 2) Removal of inorganic salts

[0037] Add 200 mL of hydrochloric acid with a concentration of 1.0 mol / L to the filtrate, heat to 50°C, stir at a constant temperature, extract for 60 minutes, filter with a 200-mesh filter, and rinse the filtrate with an appropriate amount of distilled water until the distilled water after washing is neutral , the filtrate obtained is crude chitin.

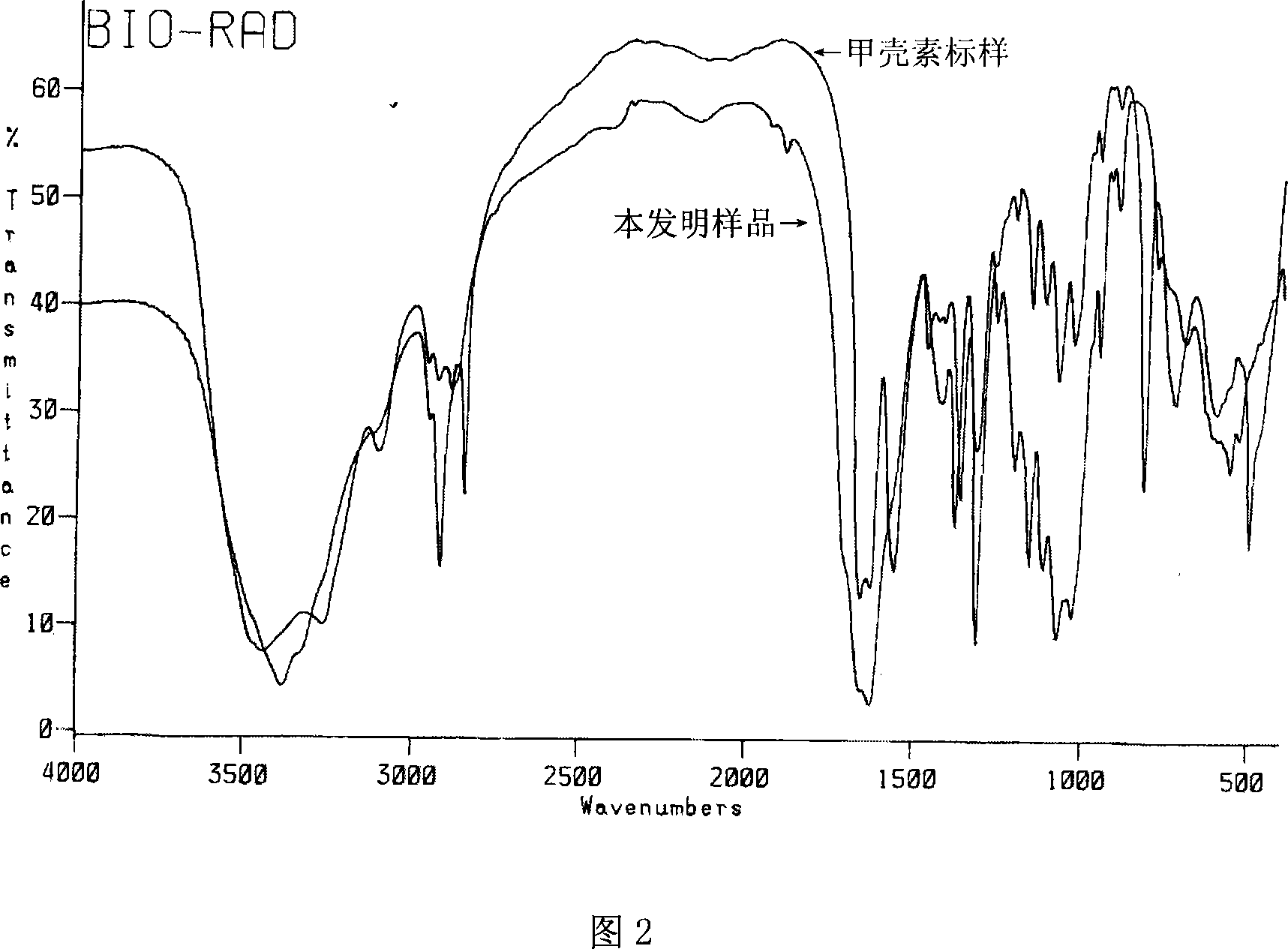

[0038] 3) Oxidative decolorization

[0039] Add dispersant deionized water to the chitin crude product, the weight o...

Embodiment 2

[0047] Follow the steps below to extract chitin from cochineal slag:

[0048] 1) Remove protein

[0049] Take 50g (dry weight) of cochineal insect residue, add 350mL of sodium hydroxide solution with a concentration of 2.0mol / L, heat and stir to mix evenly, heat to 90°C, react for 3 hours, and filter the reaction solution with a 200-mesh filter , the resulting filtrate was rinsed with an appropriate amount of distilled water until the rinsed distilled water was neutral.

[0050] 2) Removal of inorganic salts

[0051] Add 200 mL of hydrochloric acid with a concentration of 2.0 mol / L to the filtrate, heat to 60°C, stir at a constant temperature, extract for 60 minutes, filter with a 200-mesh filter, and rinse the filtrate with an appropriate amount of distilled water until the distilled water after washing is neutral , to obtain crude chitin.

[0052] 3) Oxidative decolorization

[0053] Add dispersant deionized water to the crude chitin, the weight of the deionized water is...

Embodiment 3

[0061] Follow the steps below to extract chitin from cochineal slag:

[0062] 1) Remove protein

[0063] Take 50g (dry weight) of cochineal insect residue, add 150mL of sodium hydroxide solution with a concentration of 1.5mol / L, heat and stir to mix evenly, heat to 70°C, react for 2 hours, and filter the reaction solution with a 200-mesh filter , the resulting filtrate was rinsed with an appropriate amount of distilled water until the rinsed distilled water was neutral.

[0064] 2) Removal of inorganic salts

[0065] Add 150 mL of hydrochloric acid with a concentration of 3.0 mol / L to the filtrate, heat to 70°C, stir at a constant temperature, extract for 30 minutes, filter with a 200-mesh filter, and rinse the filtrate with an appropriate amount of distilled water until the distilled water after washing is neutral , to obtain crude chitin.

[0066] 3) Oxidative decolorization

[0067] Add the dispersant deionized water to the crude chitin, the weight of the deionized wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com