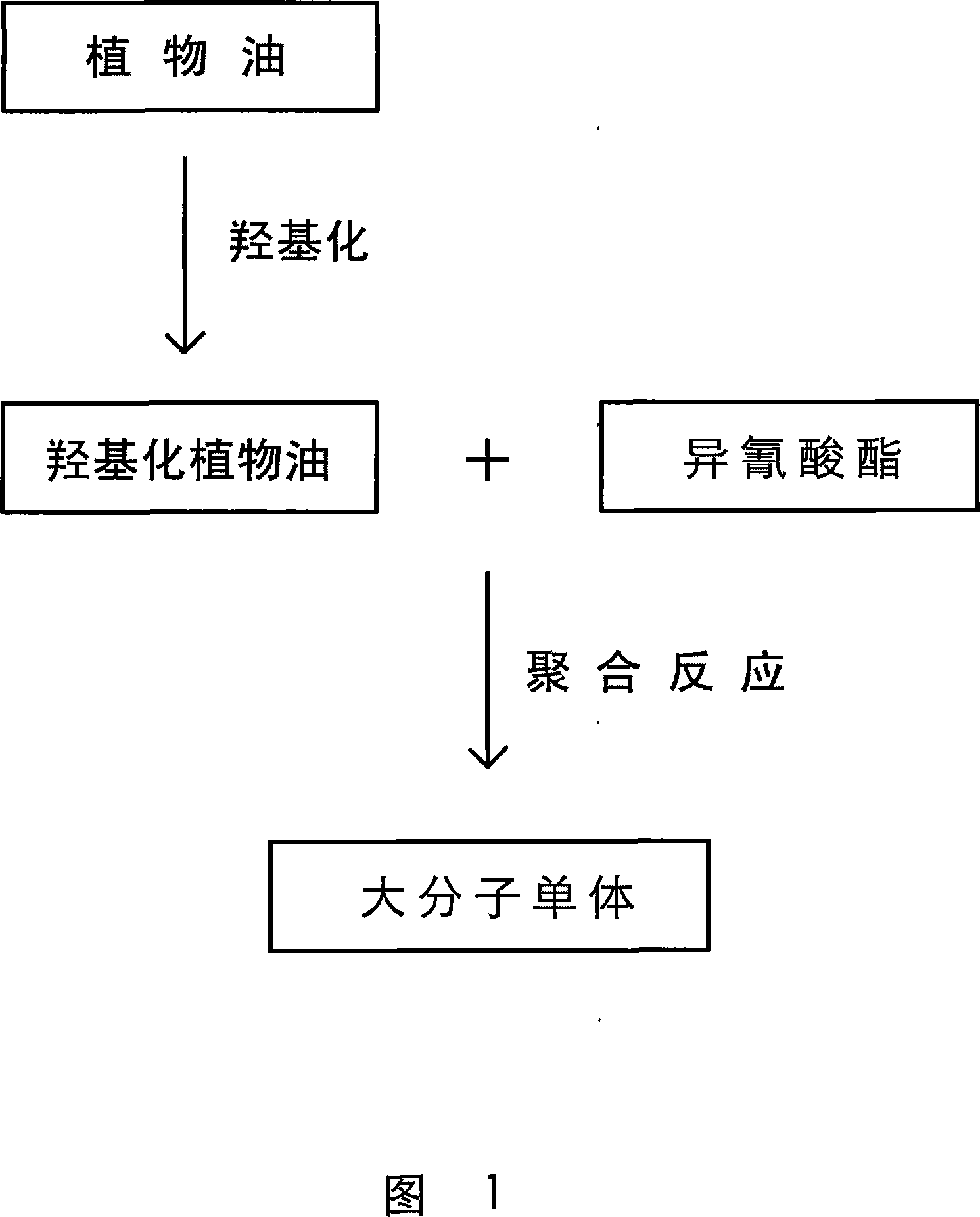

Method for synthesizing macromonomer for polymer polyol by plant oil and uses thereof

A macromonomer and polymer synthesis technology, which is applied in the field of polymer polymerization, can solve the problems of small particles, high price, and cannot but reduce the stability of polymer polyols, and achieve the effect of small particles and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

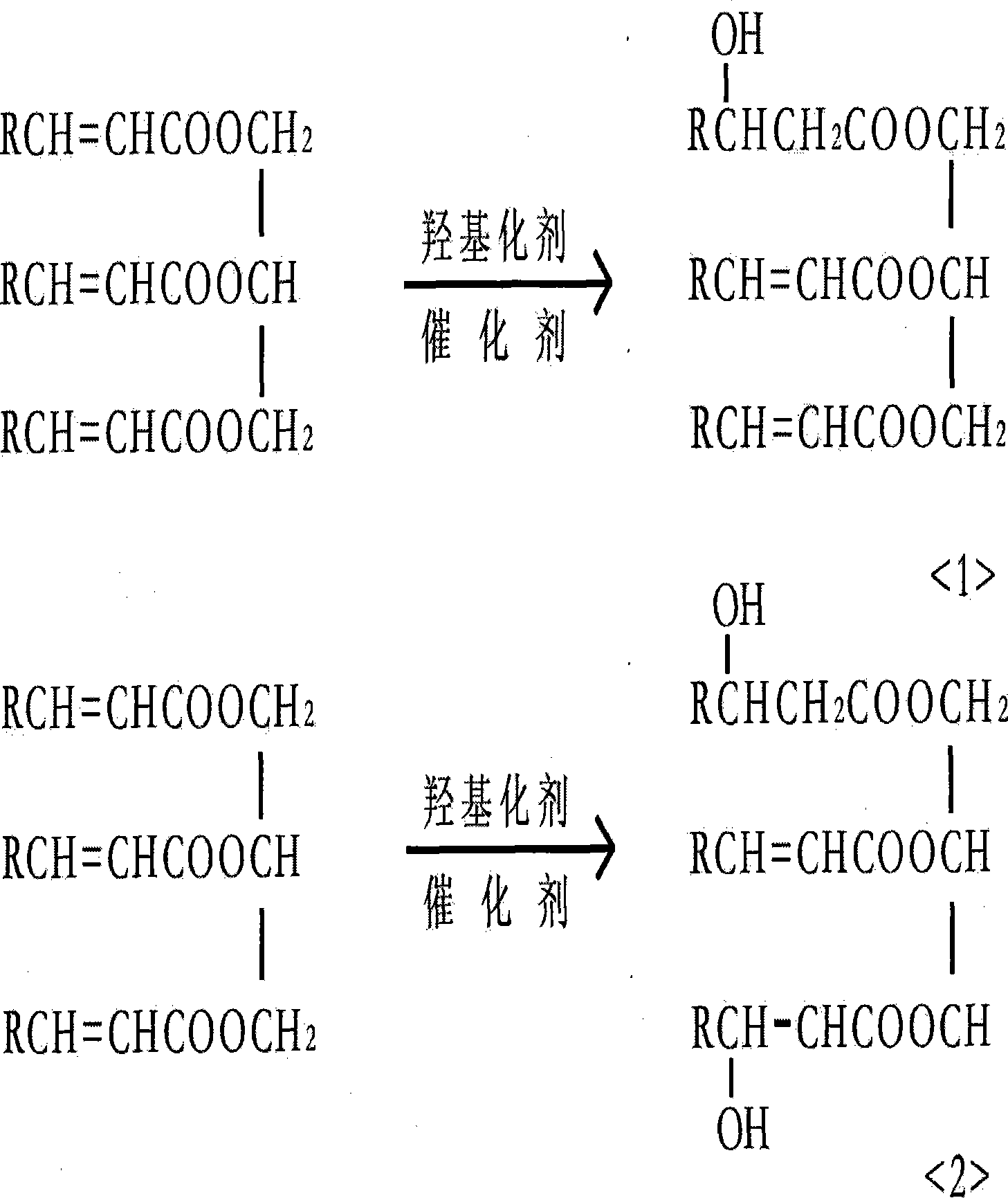

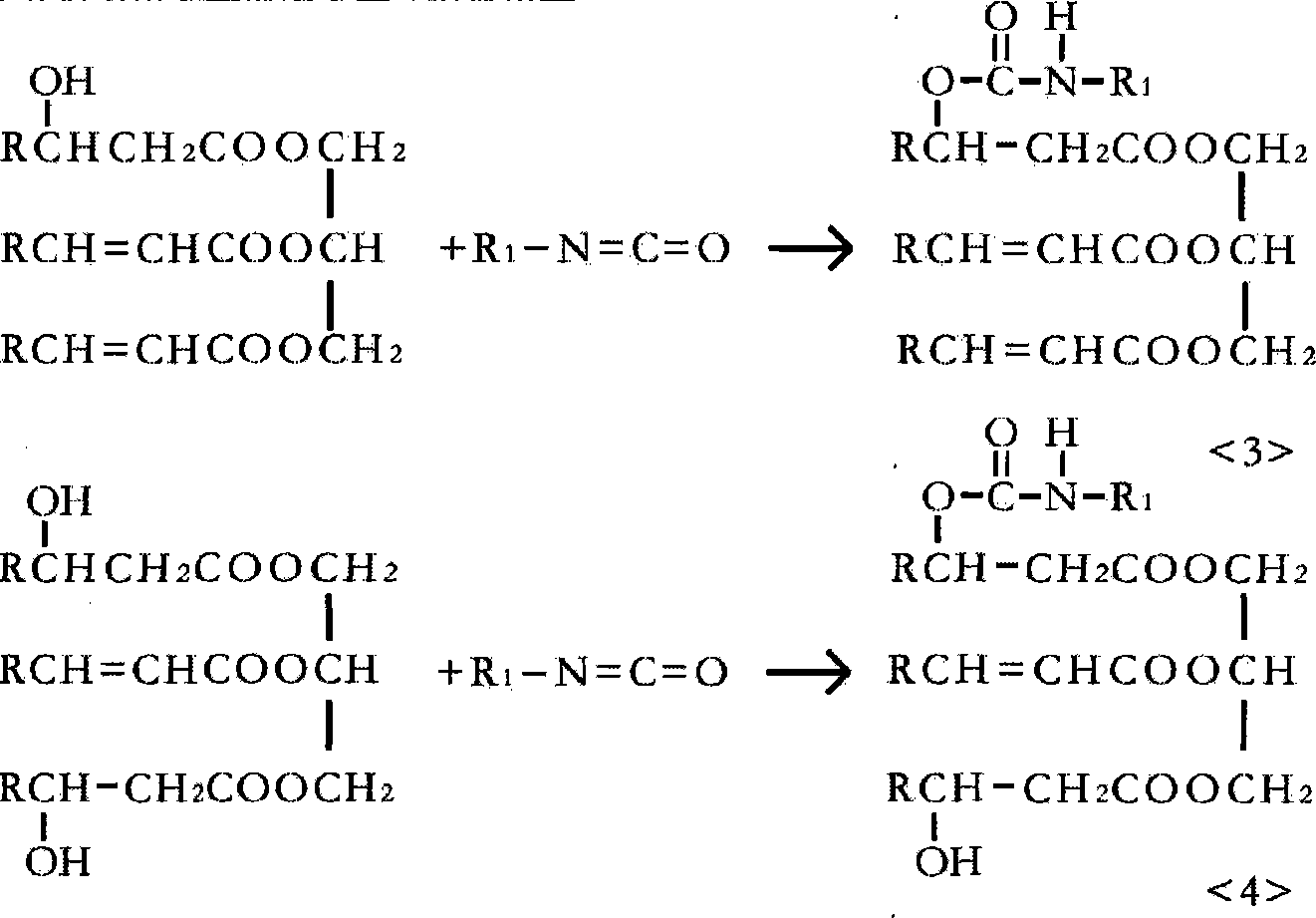

[0040] Add 500g of soybean oil and 50g of 80% formic acid in a 1L glass kettle, stir for 10 minutes, add dropwise 120g of 30% hydrogen peroxide, the mol ratio of hydrogen peroxide to soybean oil is 1.93, and the mol ratio of catalyst carboxylic acid to soybean oil is 1.59, react at 50-55°C for 5 hours, heat up to 100-110°C, reflux for 6 hours, pass through the ion exchange resin, wash twice with distilled water, and vacuum dehydrate at 110°C until the water content is less than 0.04%. This product is hydroxylated vegetable oil A. The hydroxyl value is 102.9 mgKOH / g, the water content is 0.05%, the unsaturated double bond is 0.20 mgN / g, and the acid value is 0.08 mgKOH / g.

Embodiment 2

[0042] Add 500 g of corn oil, 70 g of 80% formic acid in a 1L glass kettle, stir for 10 minutes, add dropwise 160 g of 30% hydrogen peroxide, the mol ratio of hydrogen peroxide to corn oil is 2.58, the ratio of catalyst carboxylic acid to corn oil The molar ratio is 2.22, react at 60-65°C for 6 hours, heat up at 100-110°C, reflux for 7 hours, pass through the ion exchange resin, wash twice with distilled water, and vacuum dehydrate at 110°C until the water content is less than 0.04%. This product is hydroxylated Vegetable oil B has a hydroxyl value of 142.5 mgKOH / g, a water content of 0.05%, an unsaturated double bond of 0.16 mgN / g, and an acid value of 0.11 mgKOH / g.

Embodiment 3

[0044] In a 1L glass kettle, add 500 g of sunflower oil, 40 g of 80% formic acid, stir for 10 minutes, add dropwise 100 g of 30% hydrogen peroxide, the mol ratio of hydrogen peroxide to sunflower oil is 1.61, the ratio of catalyst carboxylic acid to sunflower oil The molar ratio is 1.27, react at 40-45°C for 4 hours, heat up at 95-105°C, reflux for 4 hours, pass through the ion exchange resin, wash twice with distilled water, and vacuum dehydrate at 110°C until the moisture is less than 0.04%. This product is hydroxyl C , the hydroxyl value is 79.2 mgKOH / g, the water content is 0.05%, the unsaturated double bond is 0.23 mgN / g, and the acid value is 0.07 mgKOH / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com