Method for preparing small-molecule imide modified carbon nano-tube

A molecular imide and carbon nanotube technology, applied in the field of materials, can solve problems such as difficult dispersion, hindering the excellent performance of carbon nanotubes, and poor heat resistance, and achieve easy control, improved mechanical properties and electrical properties, and preparation methods simple and easy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Preparation of carboxylated carbon nanotubes

[0021] First mix 500mg MWNT with 150ml H 2 SO 4 with HNO 3 mixed solution (98%H 2 SO 4 : 68% HNO 3 = 3:1) mixed, and reflux reaction for 4 hours at 35-40° C. and ultrasonic vibration. Then filter with a metafluoride membrane with a pore size of 0.45 μm, and wash with water until the pH is neutral. The product was placed in a vacuum oven and dried under vacuum at 40°C for 24h. Then the above acidified and washed product was placed in H 2 SO 4 with H 2 o 2 mixed solution (98%H 2 SO 4 : 30%H 2 o 2 =4:1) at 70°C for 2h. Then filter with a metafluoride membrane with a pore size of 0.45 μm, and wash with water until the pH is neutral. The product was placed in a vacuum oven and dried under vacuum at 40°C for 24h.

Embodiment 2

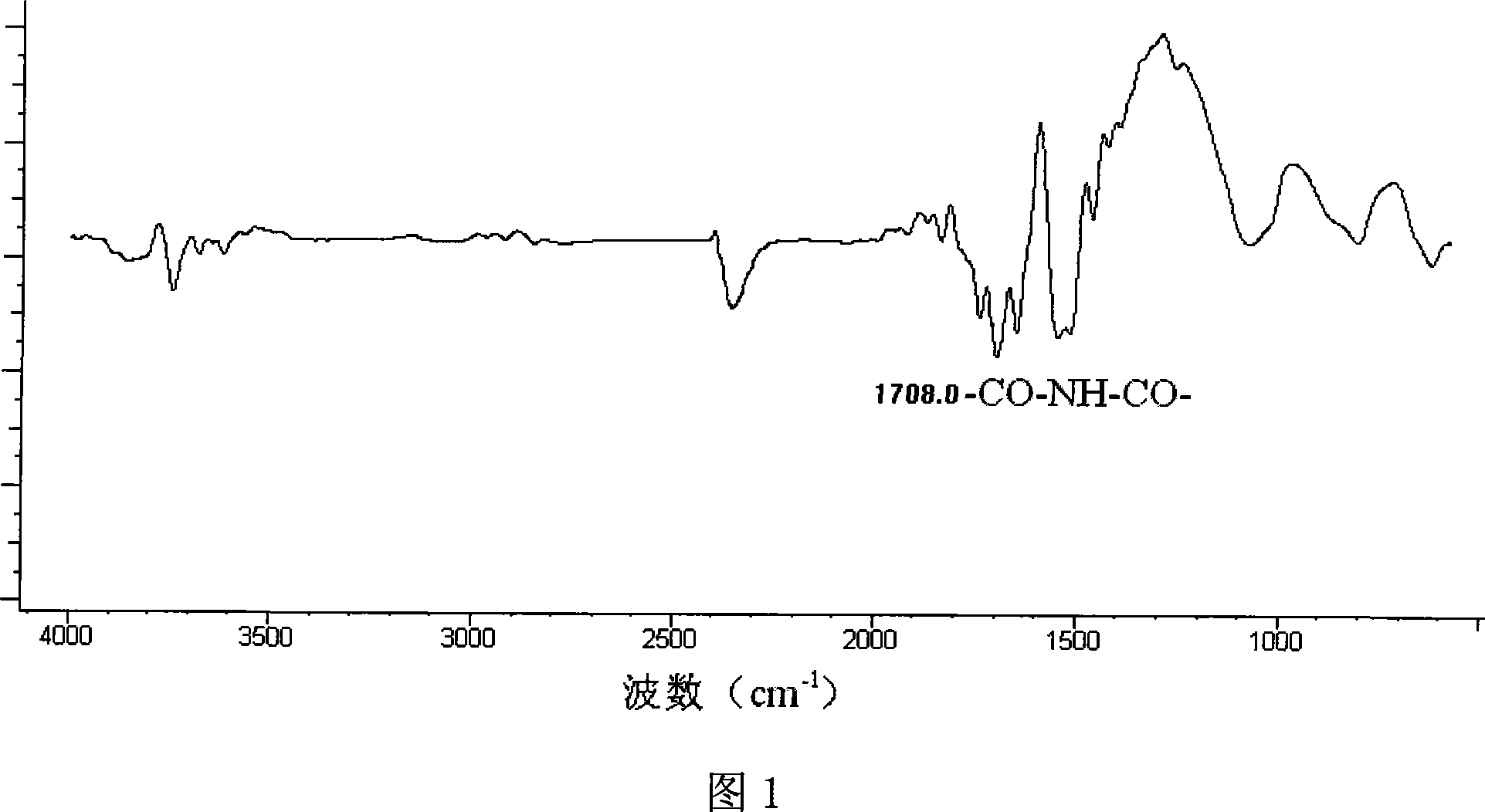

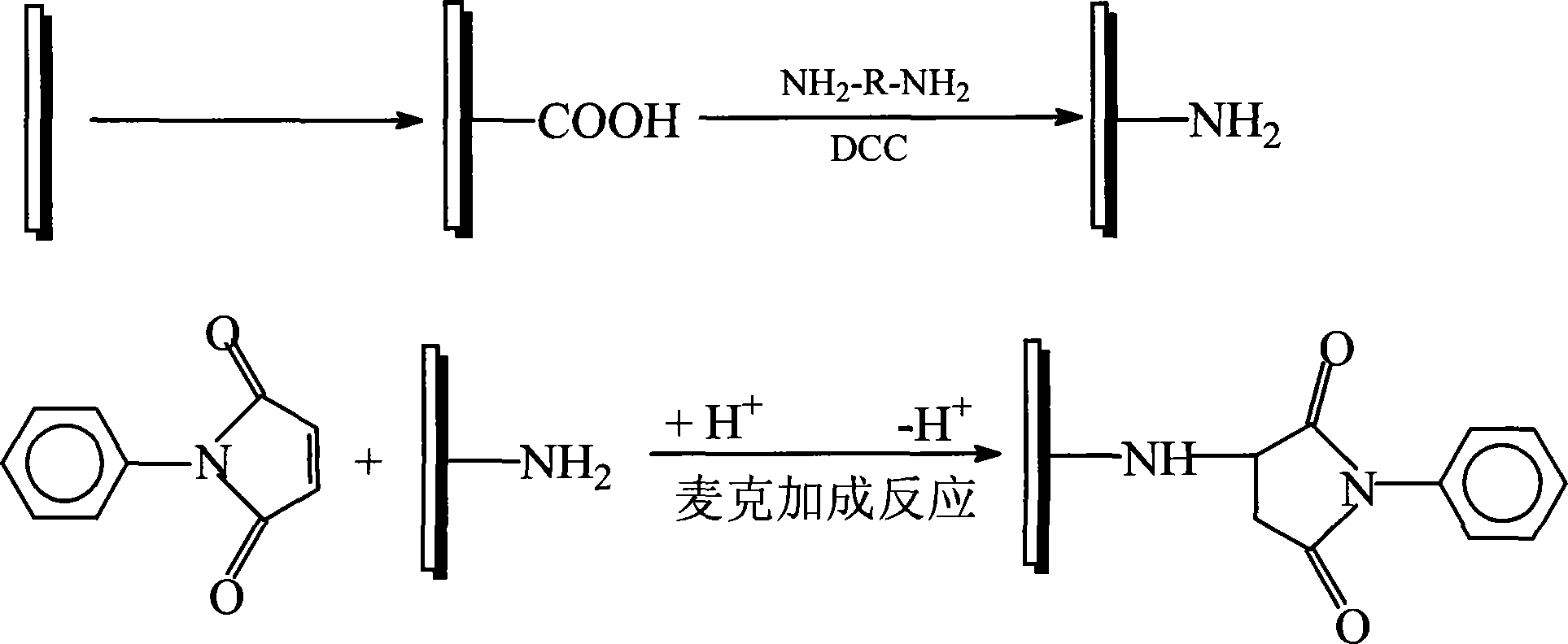

[0022] Embodiment 2: the preparation of multi-walled carbon nanotube-g-ethylenediamine-g-nitrophenylmaleimide, its operational route is as follows:

[0023]

[0024] Step 1: Put 400 mg of acidified carbon nanotubes prepared in Example 1 into a reaction flask, add 8 g of condensing agent N,N-diisopropylcarbodiimide, and 20 ml of ethylenediamine, and mix evenly. Reflux in 50ml of N,N dimethylformamide in an oil bath at 120°C for 24h. After the reaction is complete, use absolute ethanol to ultrasonically wash away the excess amine, filter with a microporous membrane (0.45μm in diameter), and repeat the cleaning for several times. The carbon nanotubes were collected until the pH value of the filtrate was neutral, and dried in vacuum at 40° C. for 24 hours to obtain black aminated multi-walled carbon nanotubes.

[0025]Step 2: Take 100 mg of aminated carbon nanotubes obtained in step (1) and place them in a reaction flask, add 5 g of nitrogen-phenylmaleimide, add catalyst 5 ml o...

Embodiment 3

[0026] Example 3: Preparation of multi-walled carbon nanotube-g-ethylenediamine-g-maleimide.

[0027] Step 1: Take 200 mg of acidified carbon nanotubes prepared in Example 1 and place them in a reaction flask, add 6 g of 1-ethyl-3-dimethylaminopropyl carbodiimide, and add 20 ml of ethylenediamine, and mix evenly . Reflux in 100ml of N,N-dimethylacetamide at 150°C for 8h. After the reaction is complete, use absolute ethanol to ultrasonically wash away the excess amine, filter with a microporous membrane (0.45μm in diameter), and repeat the washing several times until The pH value of the filtrate was neutral, and the carbon nanotubes were collected and vacuum-dried at 40° C. for 24 hours to obtain black aminated multi-walled carbon nanotubes.

[0028] Step 2: Take 100 mg of aminated carbon nanotubes obtained in step (1) and place them in a reaction flask, add 13 g of maleimide, add 5 ml of glacial acetic acid as a catalyst, and use 50 ml of diethyl ether as a solvent, reflux at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com