Granular nano material as rubber stuffing and its prepn

A nano-material and granular technology, applied in the field of nano-materials, can solve the problems of nano-material packaging, storage and transportation, shelf life impact, affecting the performance and effect of nano-materials, unstable quality of rubber products, etc., to facilitate promotion and reduce agglomeration Phenomenon, the effect of easy packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

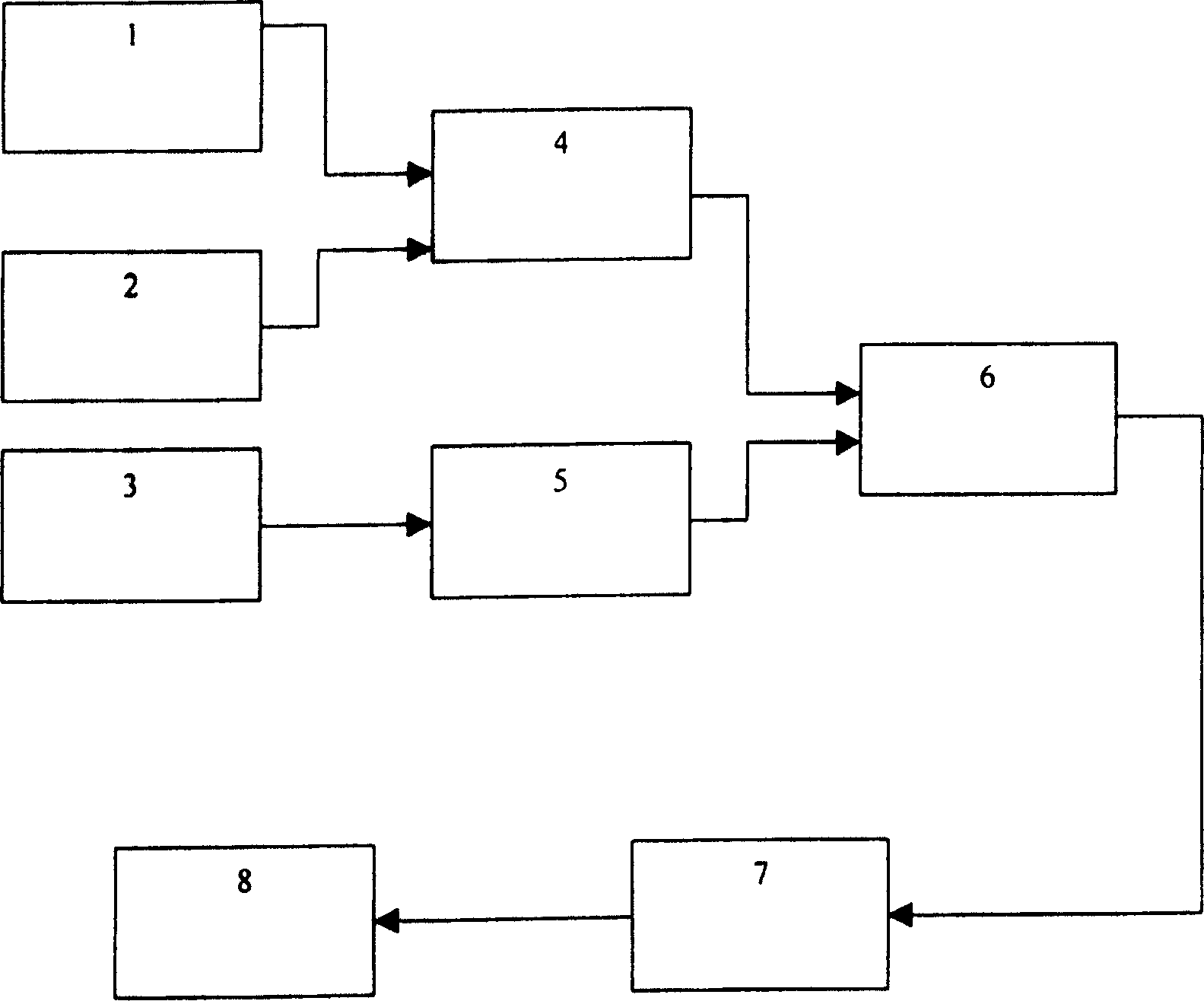

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 The granular calcium carbonate nanomaterial and preparation method thereof of rubber filling:

[0017] 1. Granular calcium carbonate nanomaterials filled with rubber: its components are: a. Nanomaterials: nano calcium carbonate; b. Surface modifier: nonionic surfactant AE0-9-fatty alcohol polyoxyethylene ether (Polymerization degree 9) and cationic imidazoline; C, dispersing binder is paraffin and petroleum resin; The specific ratio of each component is: nano-calcium carbonate: AE0-9-fatty alcohol polyoxyethylene ether (polymerization degree 9): cationic Imidazoline: paraffin: petroleum resin=65%: 5%: 5%: 15%: 10%, (percentage by weight).

[0018] 2. The preparation method of the granular calcium carbonate nanomaterials filled with rubber: the components and proportions of the granular nanomaterials filled with rubber in this example are the same as those described in 1 of this example, and each component is weighed for future use. , then add nano-calcium ...

Embodiment 2

[0019] Embodiment two rubber-filled granular graphite nanomaterials and preparation method thereof:

[0020] 1. Granular graphite nanomaterials filled with rubber: its components are: a. Nanomaterials: nanoscale graphite; b. Surface modifier: titanate coupling agent; c. Dispersed binder: eighteen Primary amine; the specific ratio of each component is: nanoscale graphite: titanate coupling agent: octadecyl primary amine = 95%: 1%: 4% (percentage by weight).

[0021] 2. The preparation method of the granular graphite nanomaterials filled with rubber: the components and proportions of the granular graphite nanomaterials filled with rubber in this example are the same as those described in 1 of this example. First, each component is weighed for future use. Then add nano-scale graphite into the mixer, heat it to 50C, start the mixer, and add titanate coupling agent; in addition, heat the dispersed binder octadecyl primary amine to 50 °C to melt it; then melt the dispersed adhesive ...

Embodiment 3

[0022] Example three rubber-filled granular zinc oxide nanomaterials and preparation method thereof:

[0023] 1. Granular zinc oxide nanomaterials filled with rubber: its components are: a. Nanomaterials: nano zinc oxide, b. Surface modifier: nonionic surfactant TX-10-nonylphenol polyoxyethylene Ether (epoxy polymerization degree 10), titanate coupling agent, hydroxyl silicone oil, c, dispersion binder: paraffin and petroleum resin; the specific ratio of each component is: nanometer zinc oxide: TX-10-nonylphenol poly Oxyethylene ether (epoxy polymerization degree 10): titanate coupling agent: hydroxyl silicone oil: paraffin: petroleum resin=40%: 10%: 5%: 5%: 10%: 30% (weight percentage).

[0024]2. The preparation method of granular zinc oxide nanomaterials filled with rubber: the components and proportions of the granular nanomaterials filled with rubber in this example are the same as those described in 1 of this example, and each component is weighed for future use. , then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com