Hollow beam gas laser

A laser, hollow technology, used in the field of optics and optical engineering, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

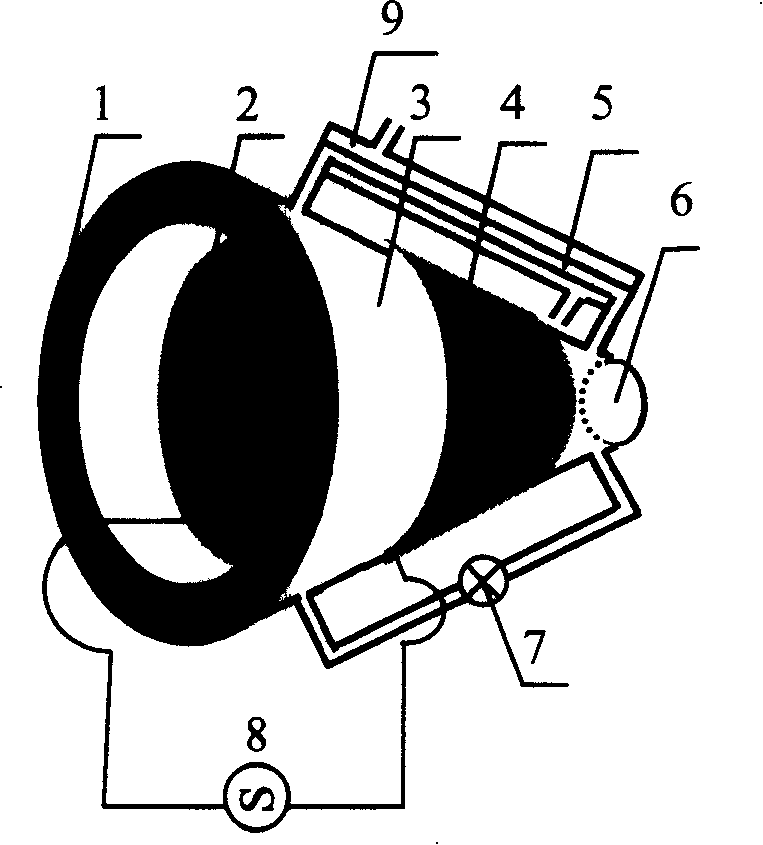

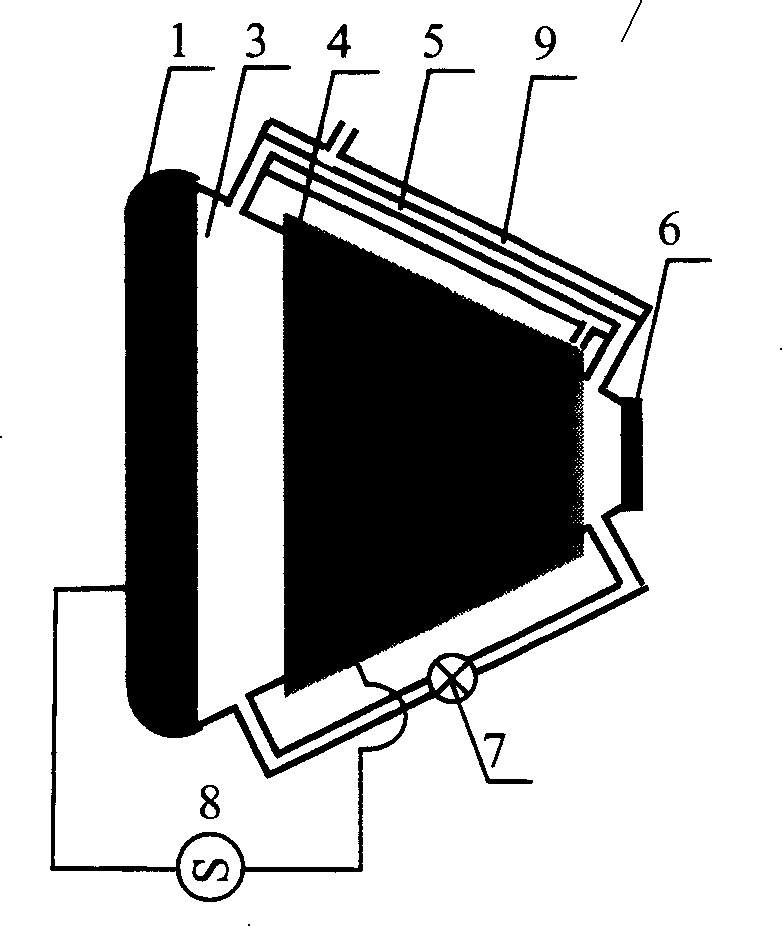

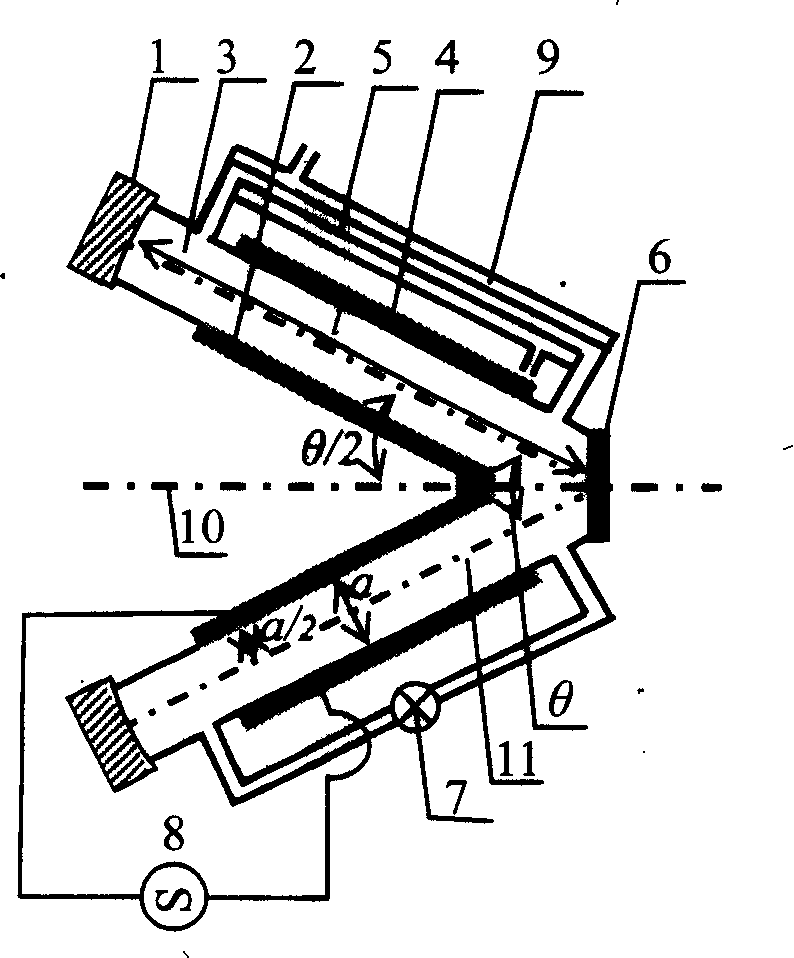

[0008] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0009] Axisymmetric circular annular curved surface reflector 1 of the present invention adopts circular optical glass or quartz block as substrate, for He-Ne laser and CO 2 The laser is suitable, and the round copper block with good density and high hardness is used as the substrate, which is suitable for high output CO 2 The laser is applicable, and their outer edge size is consistent with our requirements. Use a hole cutting device to cut the middle part according to the inner edge size of the ring mirror, but the middle part should be glued together with the ring block for grinding processing. The abrasive tool for grinding the mirror surface is made of low-carbon steel material and processed by CNC machine tools according to the design. Since the mirror surface does not have a single center of curvature, the abrasive tool does not have ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com