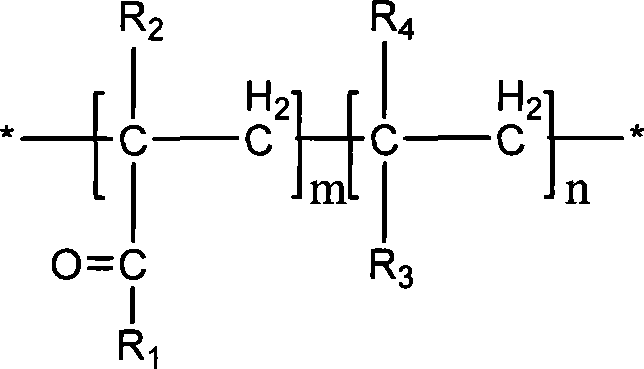

Environment response polymer brush and preparation method thereof

An environment-responsive, copolymer technology, which is applied to a pH-responsive copolymer brush and its preparation, has temperature, environment-responsive copolymer brushes and the field of preparation thereof, and can solve the problem of not being able to obtain temperature-responsive copolymers, functional Can not meet the problems such as well, to achieve the effect of simple synthesis method and rich source of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (a) Dissolve 35.5 g of monoamino-terminated PEO with a molecular weight of 1000 in 50 ml of chloroform, transfer the solution to a 250 ml three-neck flask with stirring, and then add 7.2 g of triethylamine. At 0°C, pass N 2 For protection, add 7.4 g of methacryloyl chloride in 20 ml of chloroform solution dropwise, control the rate of addition, and drop it within 1 hour. The reaction was continued at 0°C for 1 hour, and then the system was warmed up to room temperature for another 8 hours. After the reaction, filter the reaction solution to remove triethylamine hydrochloride, pour the filtrate into 500ml of n-hexane, stir at room temperature for 5 hours, filter and wash the precipitate with ether, and vacuum dry at 40°C for 24 hours to obtain macromolecular single Bulk methacrylamide-terminated polyoxyethylene (PEO-MA).

[0024] (b) 0.0046g of azobisisobutylcyanide (AIBN), 2.20g of PEO-MA and 0.84g of vinylpyridine were dissolved in isopropanol and reacted at 60°C for...

Embodiment 2

[0028] (a) Dissolve 11.5 g of monoamino-terminated PEO with a molecular weight of 1000 in 20 ml of chloroform, transfer the solution to a 250 ml three-neck flask with stirring, and then add 2.8 g of triethylamine. At 0°C, pass N 2 For protection, add 2.9 g of methacryloyl chloride in 10 ml of chloroform solution dropwise, control the rate of addition, and drop it within 1 hour. The reaction was continued at 0° C. for 1 hour, and then the system was warmed to room temperature for another 15 hours. After the reaction is over, filter the reaction solution to remove triethylamine hydrochloride, pour the filtrate into 300ml of n-hexane, stir at room temperature for 5 hours, filter and wash the precipitate with ether, and dry it in vacuum at 40°C for 24 hours to obtain macromolecular single Bulk methacrylamide-terminated polyoxyethylene (PEO-MA).

[0029] (b) 0.0049g of azobisisobutylcyanide (AIBN), 1.47g of PEO-MA and 0.84g of vinylpyridine were dissolved in isopropanol and react...

Embodiment 3

[0031] (a) Dissolve 35.5 g of monoamino-terminated PEO with a molecular weight of 1000 in 60 ml of chloroform, transfer the solution to a 250 ml three-neck flask with stirring, and then add 7.9 g of triethylamine. At 0°C, pass N 2 For protection, add 8.2 g of methacryloyl chloride in 20 ml of chloroform solution dropwise, control the rate of addition, and drop it within 1 hour. The reaction was continued at 0°C for 1 hour, and then the system was warmed up to room temperature for another 8 hours. After the reaction, filter the reaction solution to remove triethylamine hydrochloride, pour the filtrate into 500ml of n-hexane, stir at room temperature for 5 hours, filter and wash the precipitate with ether, and vacuum dry at 40°C for 24 hours to obtain macromolecular single Bulk methacrylamide-terminated polyoxyethylene (PEO-MA).

[0032] (b) 0.0044g of azobisisobutylcyanide (AIBN), 1.10g of PEO-MA and 0.84g of vinylpyridine were dissolved in isopropanol and reacted at 60°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com