Method for producing sodium bentonite with calcium bentonite

A technology of sodium-based bentonite and calcium-based bentonite, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., to achieve the effects of simple and easy process, convenient recycling and use, and good modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

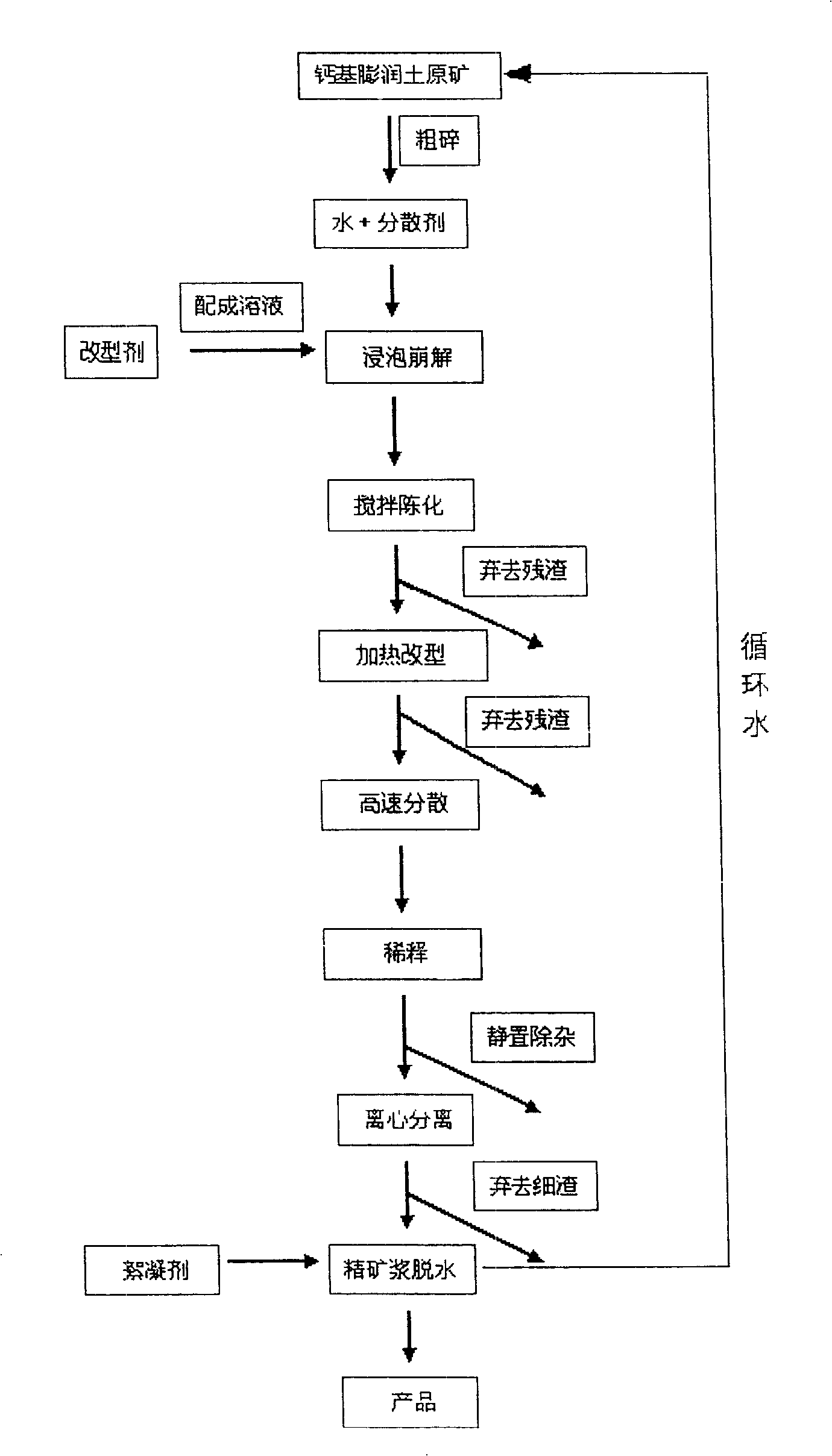

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail with a specific embodiment below:

[0028] According to the technical process of the present invention, the natural calcium-based bentonite in Xinghe County, Inner Mongolia is purified and modified by sodium, and the specific steps are:

[0029] 1. Mix 1g of dispersant (NaPO 3 ) 6 Add 800g of pure water, stir to dissolve, add 200g of calcium-based bentonite ore coarsely crushed to a particle size of about 1cm into the above solution, soak and disintegrate, then stir and mix well.

[0030] 2. Add 8g of modifier Na 2 CO 3 After making a saturated aqueous solution, add it to the above-mentioned mixing system, and then stir to make it fully mix and age for 18 hours.

[0031] 3. After discarding the large particles of impurities in the lower layer, heat the upper layer system to 90°C, stir vigorously at this temperature and replenish water in time to make the system fully react for 1 hour.

[0032] 4. After standing stil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com