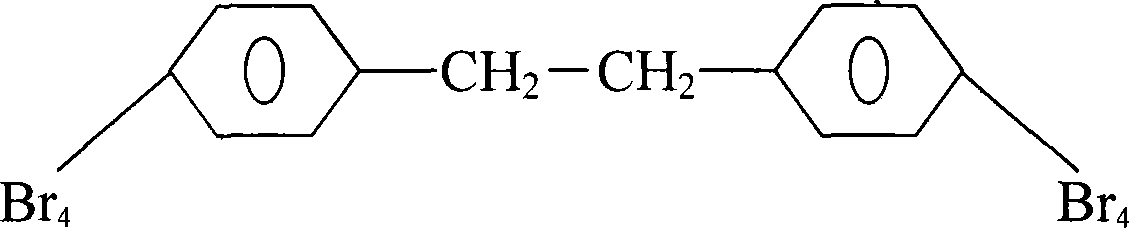

C14H4Br8 and synthesizing process

A technology of octabromodiphenylethane and its synthesis method, which is applied in the field of engineering plastics, can solve the problems of uneven dispersion, reduced plastic strength, and high melting point, and achieve the effects of good dispersion effect, reduced loss, and simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) In a 1000mL four-necked bottle, put 72.8g of diphenylethane into 400mL of dibromomethane and dissolve it in 400mL of dibromomethane, then add 7.28g of iron powder, cool down with ice water, slowly add 175mL of bromine dropwise, keep the temperature below 20°C during the dropwise addition, add After keeping warm for 2 hours, add 50mL of 15% sodium sulfite to neutralize until the system is white or colorless, then separate into layers at rest, discard the water layer, and separate the materials;

[0040] (2) Add 100mL of 15% hydrochloric acid and 50mL of water respectively, raise the temperature and reflux for 30min, let the layers stand still, discard the water layer, and separate the materials;

[0041] (3) Add 300mL of water and 10mL of OS (MS-1) surfactant respectively, heat up and distill, raise to 85°C, the material precipitates, filter with suction, and dry in an oven at 100°C to obtain a white powder of octabromodiphenylethane 320g, yield 93.46%.

[0042] ana...

Embodiment 2

[0051] Others are the same as in Example 1, and the organic solvent is changed to 600ml of dichloromethane to obtain 322g of octabromodiphenylethane as a white powder, with a yield of 96.40%.

[0052] Analysis test: bromine content 80.06%, melting point 165-175 ℃, volatile matter 0.15%, whiteness 90.4.

Embodiment 3

[0054] Others are the same as in Example 1, the catalyst is replaced by 20 g of iron tribromide to obtain 320 g of white powder octabromodiphenylethane, the yield is 93.46%, the bromine content is 80.10%, the melting point is 165-175°C, the volatile matter is 0.15%, and the whiteness 90.4.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com