Novel technique for synthesizing quaternary ammonium salt

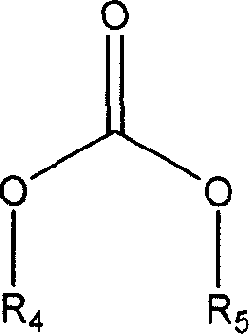

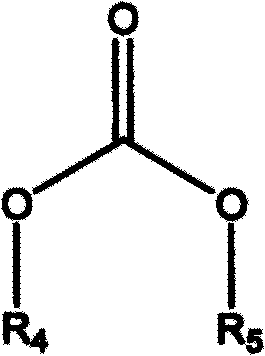

A synthesis process and quaternary ammonium salt technology, which is applied in the field of direct reaction of carbonic acid diester and amine salt to prepare quaternary ammonium salt under the condition of no catalyst, can solve the problems that the catalyst cannot be reused and the product is impure, and achieve high product purity , The effect of low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

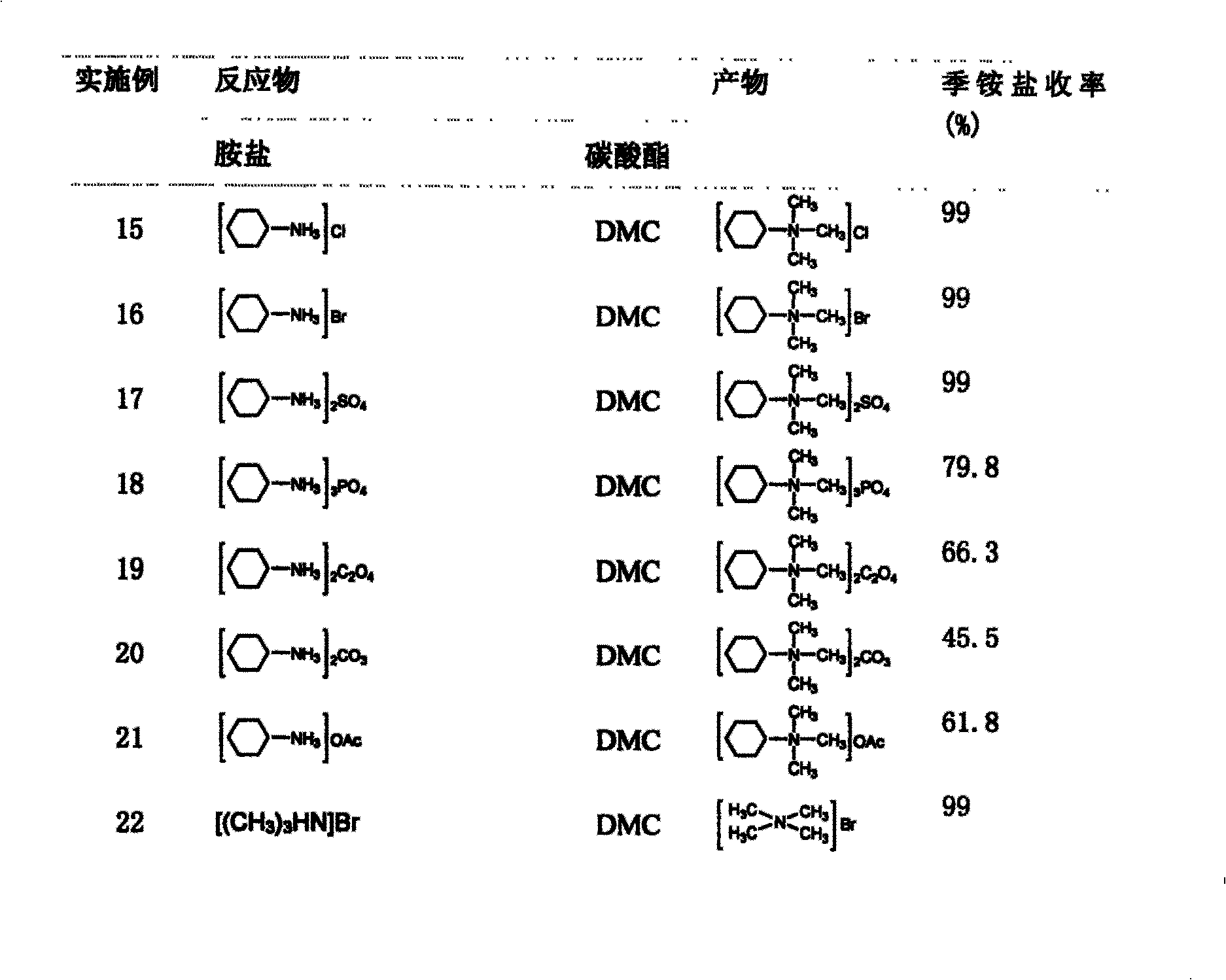

Examples

Embodiment 1

[0016] Weigh 927g of dodecylamine and place it in a beaker, add concentrated hydrochloric acid dropwise (the total amount of HCl added is about 180g), stir magnetically, remove about 80% of the water by evaporation in a constant temperature water bath after the neutralization reaction is completed, and then vacuum dry to obtain Product lauryl ammonium chloride; Take by weighing 1109g lauryl ammonium chloride and 455g dimethyl carbonate respectively, join in the 10L autoclave successively, after blowing away the air in the still with nitrogen, airtight reaction, The reaction temperature was 170°C, and stirring was started after the reaction temperature reached 170°C, and the reaction time was 8 hours; after the reaction, about 1308g of dodecyltrimethylammonium chloride was obtained.

Embodiment 2

[0018] Take by weighing 927g dodecylamine and place it in a beaker, add aqueous hydrogen bromide solution (about 405g of HBr adding total amount) drop by drop, magnetically stir, remove about 80% water with constant temperature water bath evaporation after neutralization reaction finishes, then vacuum Dry to obtain the product dodecyl ammonium bromide; weigh 1331g of dodecyl ammonium bromide and 455g of dimethyl carbonate respectively, add them to a 10L autoclave in turn, blow away the air in the autoclave with nitrogen, and seal the Reaction, the reaction temperature is 170°C, stirring is started after the reaction temperature reaches 150°C, and the reaction time is 4 hours; after the reaction is completed, about 1540g of dodecyltrimethylammonium bromide can be obtained.

Embodiment 3

[0020] Take by weighing 1000g dodecyl dimethylamine and place it in a beaker, add concentrated hydrochloric acid (HCl adds about 171g total amount) dropwise, magnetically stir, remove about 80% water with constant temperature water bath evaporation after neutralization reaction finishes, then Vacuum-dried to obtain the product dodecyldimethylammonium chloride; Weigh 1000g of dodecyldimethylammonium chloride and 365g of dimethyl carbonate respectively, add them to a 10L reaction kettle in turn, and blow them away with nitrogen After the air in the still, airtight reaction, reaction temperature 170 ℃, start to stir after reaction temperature reaches 160 ℃, reaction time 8 hours; after reaction finishes, make about 1050g of dodecyltrimethylammonium chloride.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com