Sidetrack etherification method integrated with catalytic cracking absorption stable system

A technology of absorption stabilization system and catalytic cracking, which is applied in the refining and cracking process treatment of multi-stage series connection, petroleum industry, refined hydrocarbon oil, etc. Multiple operational flexibility, olefin content reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

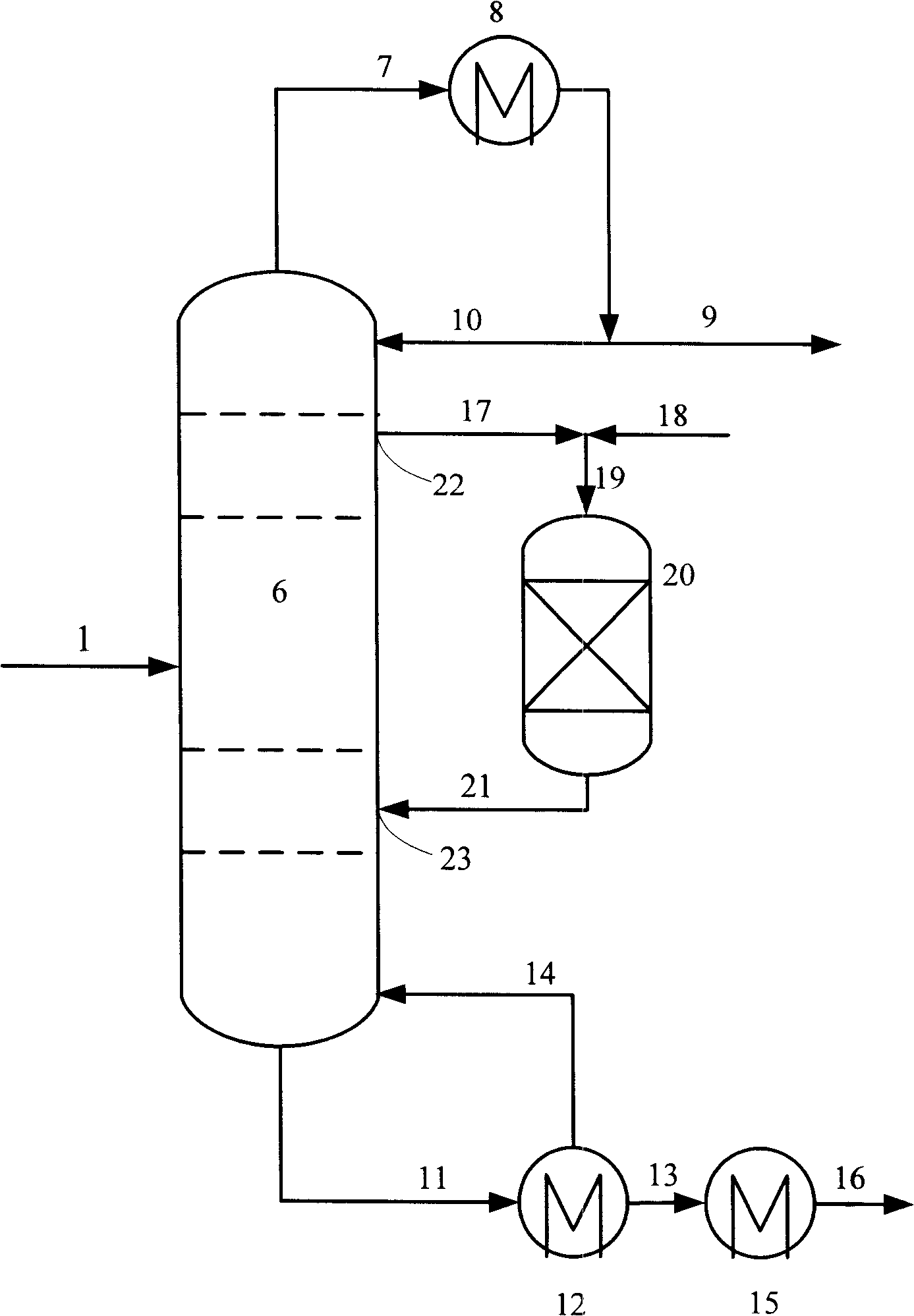

[0053] The hydrocarbon etherification raw material that present embodiment adopts is the C that contains 20% isobutene 4 Fraction, C 4 After the distillate is mixed with methanol, it enters the stabilizing tower, and a side line outlet is provided at 80% of the tower height of the stabilizing tower. The liquid phase stream extracted from the side line outlet is mixed with methanol and then enters the etherification reactor, and is mixed with etherification catalyst A Contact, at alcohol / hydrocarbon mass ratio 0.5, reaction temperature 80°C, reaction pressure 1.7MPa, based on the liquid phase flow at the side outlet, the weight space velocity of the feed liquid is 2.0h -1 The reaction is carried out under certain conditions, and the reaction product is not separated, and then enters the tower from the side line feed port at 50% of the tower height of the stabilized tower for fractionation, and the gas component is obtained from the top of the stabilized tower. MTBE is obtained...

Embodiment 2

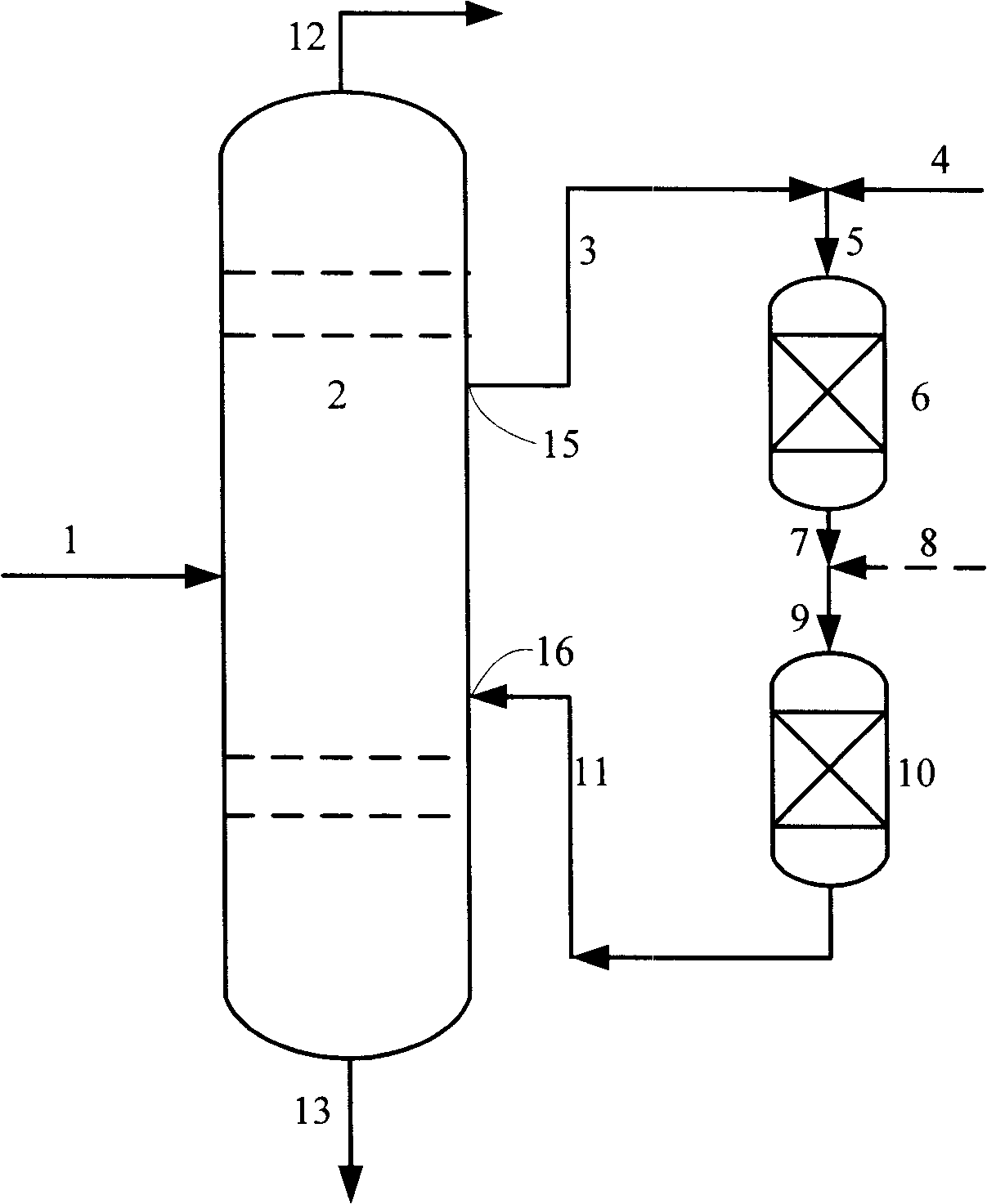

[0057] The hydrocarbon etherification raw material used in this embodiment is the same catalytic cracking deethanized gasoline 1 as that of Comparative Example 1. After the catalytic cracked deethanized gasoline 1 is mixed with methanol, it enters the stabilizing tower. There is a side line outlet, and the liquid phase stream drawn from the side line outlet is mixed with methanol and then enters the etherification reactor, where it contacts with the catalytic cracking catalyst GOR-II, at an alcohol / hydrocarbon mass ratio of 0.2, a reaction temperature of 100°C, and a reaction pressure of 1.5MPa, based on the liquid phase flow at the side line outlet, the weight space velocity of the feed liquid is 4.0h -1 The reaction is carried out under the condition of the stable tower, and the reaction product is not separated from the side line feed port at 50% of the tower height of the stable tower and then enters the tower for fractionation. The operating conditions of the stable tower ...

Embodiment 3

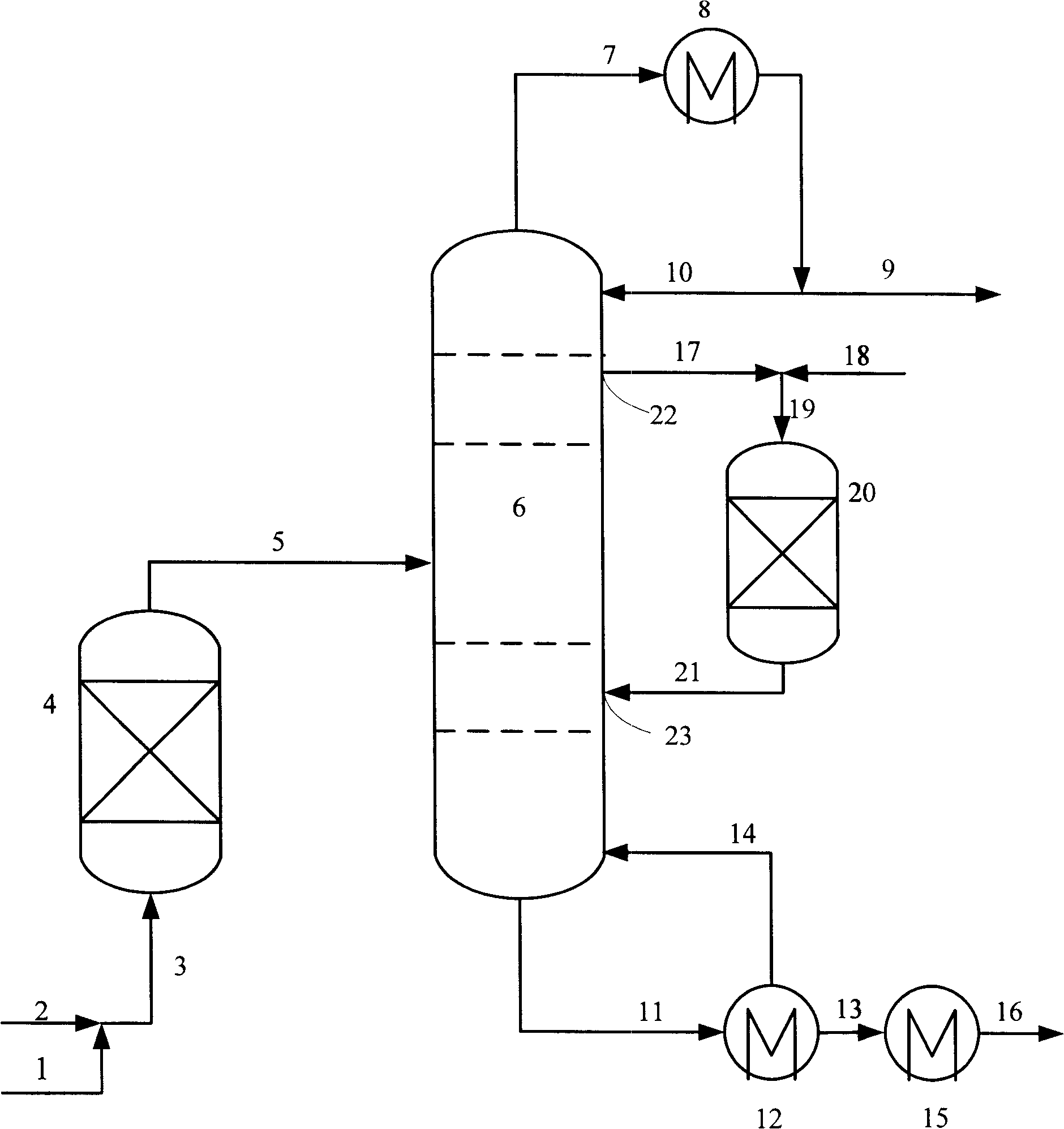

[0062] The hydrocarbon etherification raw material used in this embodiment is the same catalytic cracking deethanized gasoline 2 as in Comparative Example 2, and the catalytic cracked deethanized gasoline 2 enters the pre-etherification reactor after being mixed with methanol, and contacts with catalytic cracking catalyst DOCP, At an alcohol / hydrocarbon mass ratio of 0.1, a reaction temperature of 120°C, and a reaction pressure of 1.5 MPa, the weight space velocity of the feed liquid is 18.0 h based on hydrocarbon etherification raw materials -1 react under the conditions. The reaction result is based on olefins, the olefin polymerization selectivity is ≤0.5%, the diolefins in the reaction product are ≤100 μg / g, and the alkali nitrogen content is ≤1 μg / g.

[0063] The reaction product of the pre-etherification reactor enters the stabilizing tower for fractional distillation, and a side line outlet is set at 60% of the tower height of the stabilizing tower, and the liquid phase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com