Modification method of calcium-based ascarite

A carbon dioxide and absorbent technology, applied in chemical instruments and methods, separation methods, chemical separation, etc., can solve problems such as threats to the safety and economic operation of equipment, decrease in carbonation conversion rate, and attenuation of absorbent performance, and achieve improved circulation. Carbonation conversion rate, lower operating costs, and the effect of less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described below in conjunction with accompanying drawing:

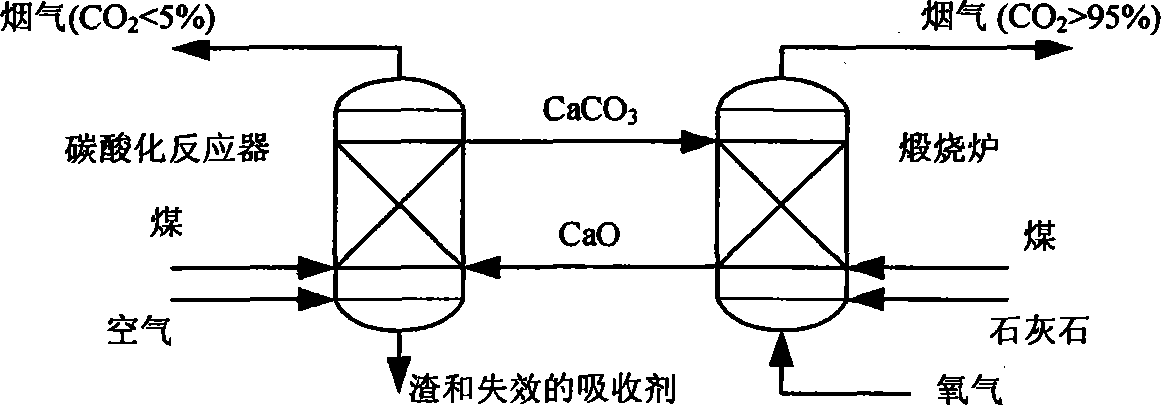

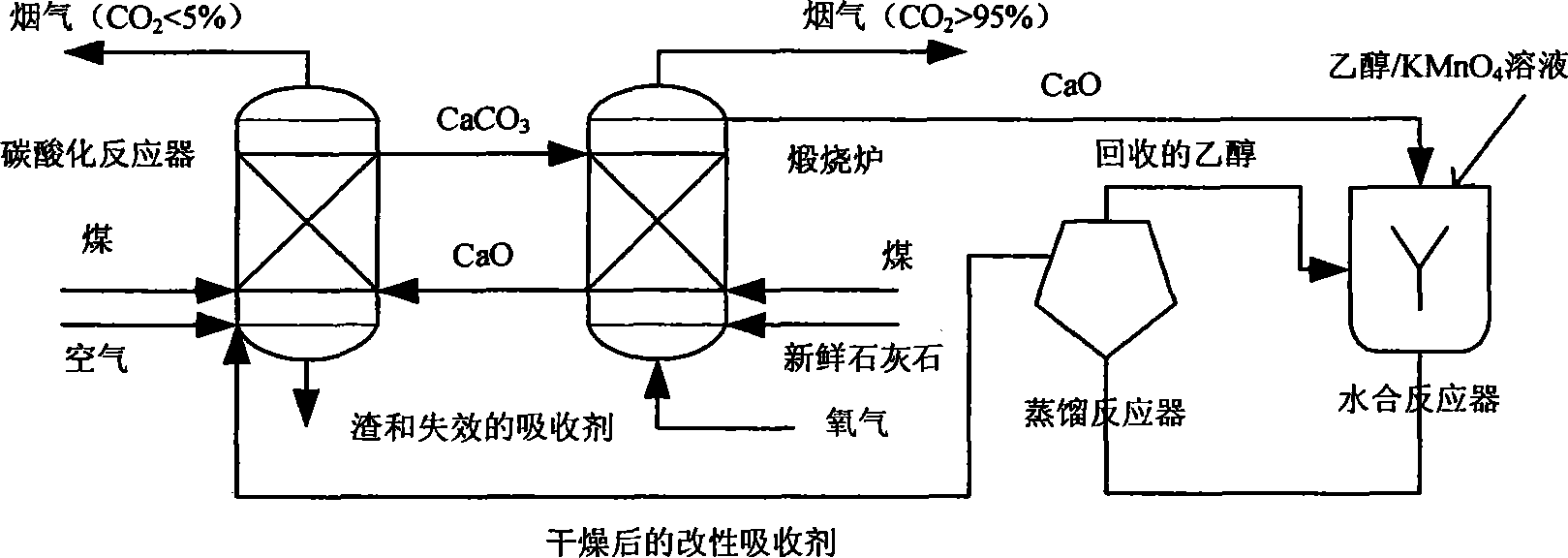

[0019] figure 2 Ca-based CO 2 Process flow for modification of absorbent during cyclic calcination / carbonation. CaCO 2 Absorbents such as limestone and dolomite enter the calciner for pyrolysis to produce CaO. CaO then enters the hydration reactor, and ethanol / KMnO 4 The solution undergoes hydration reaction and undergoes modification. The modified calcium-based CO 2 The absorbent is transported to a distillation reactor where the absorbent is dried and ethanol is recovered. The modified absorbent then enters the carbonation reactor to absorb the CO produced by combustion or gasification 2 . At the same time, a small amount of fresh calcium-based absorbent is added, and after entering the calciner, it is passed through ethanol / KMnO 4 The solution is modified, and the operation is repeated.

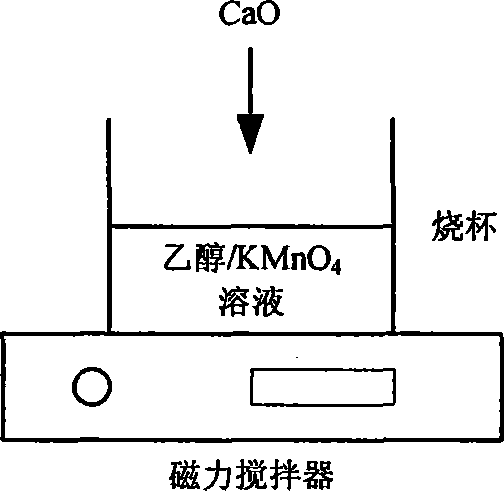

[0020] image 3 Ca-based CO 2 Schematic diagram of the absorbent modification proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com