Synthetic method of solid phase catalyst with organic microballoons load gold nano grain

A gold nanoparticle, solid-phase catalyst technology, applied in the direction of organic compound/hydride/coordination complex catalyst, chemical instrument and method, metal/metal oxide/metal hydroxide catalyst, etc., can solve the polyelectrolyte price Expensive, chemical modification synthesis steps are increased, etc., to achieve the effect of simple post-processing and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

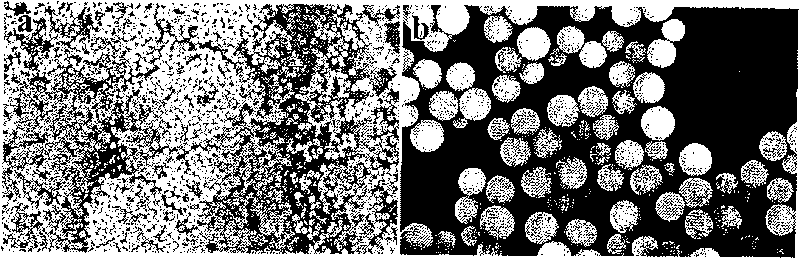

Embodiment 1

[0023] (1) In a 25ml round bottom flask, add 9mg of sodium metal into 5ml of absolute ethanol and react for 15min.

[0024] (2) Add 30 mg of (2,5-dimercapto-1,3,4-thiadiazole) into the round bottom flask in step (1), and stir magnetically at room temperature for 2.5 hours.

[0025] (3) 21 mg of perchlorinated acenaphthylene was dissolved in 10 ml of toluene.

[0026] (4) Mix the solutions obtained in steps (2) and (3) in a 50ml round-bottomed flask with a stopper, and keep the temperature at 20°C for 48h.

[0027] (5) Pour out the solution after cooling to room temperature, and centrifuge with a 5ml centrifuge tube. The resulting solid precipitate is washed with toluene, ethanol, and water five times in sequence, and the precipitate is finally dispersed in ethanol.

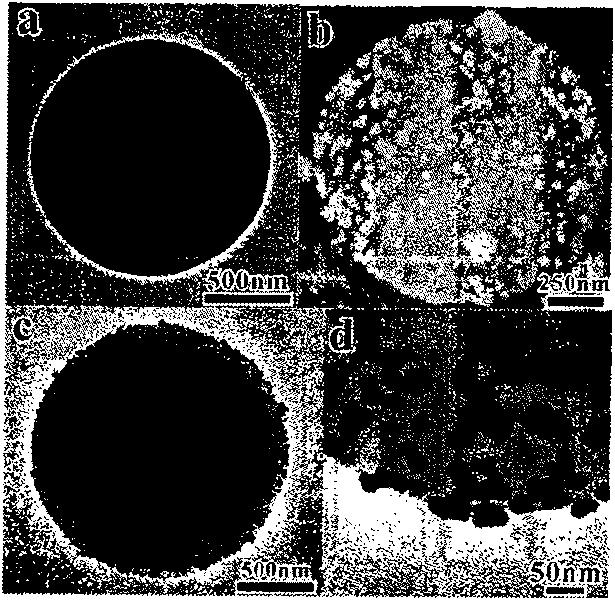

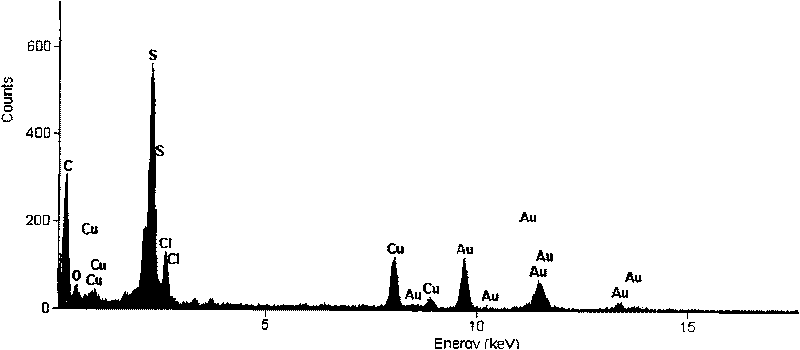

[0028] (6) Mix 1 mg of microspheres washed in step 5 and 0.1 ml (aqueous solution with a concentration of 25.4 mmol / L) of chloroauric acid (HAuCl 4 ) mixed in 10ml of ethanol and water mixed reagent (wherein ethan...

Embodiment 2

[0032] (1) In a 25ml round bottom flask, add 9mg of sodium metal into 5ml of absolute ethanol and react for 30min.

[0033] (2) Add 30 mg of (2,5-dimercapto-1,3,4-thiadiazole) into the round bottom flask in step (1), and stir magnetically at room temperature for 2.5 hours.

[0034] (3) Dissolve 21 mg of perchloronaphthalene in 10 ml of toluene.

[0035] (4) Mix the solutions obtained in steps (2) and (3) into a 50ml round-bottomed flask with a stopper, and keep the temperature at 30°C for 24h.

[0036] (5) After cooling to room temperature, the solution was poured out, centrifuged with a 5ml centrifuge tube, and the obtained solid precipitate was washed with toluene, ethanol, and water 5 times respectively, and the precipitate was finally dispersed in ethanol.

[0037] (6) Mix 1 mg of the microspheres washed in Step 5 and 0.2 ml (aqueous solution with a concentration of 25.4 mmol / L) of chloroauric acid (HAuCl 4 ) mixed in 10ml of ethanol and water mixed reagent (wherein etha...

Embodiment 3

[0040] (1) In a 25ml round bottom flask, add 9mg of sodium metal into 5ml of absolute ethanol and react for 30min.

[0041] (2) Add 30 mg of (2,5-dimercapto-1,3,4-thiadiazole) into the round bottom flask in step (1), and stir magnetically at room temperature for 2.5 hours.

[0042] (3) 21 mg of perchlorinated acenaphthylene was dissolved in 10 ml of toluene.

[0043] (4) Mix the solutions obtained in steps (2) and (3) in a 50ml round-bottomed flask with a stopper, and keep the temperature at 40°C for 12h.

[0044] (5) After cooling to room temperature, the solution was poured out, centrifuged with a 5ml centrifuge tube, and the obtained solid precipitate was washed with toluene, ethanol, and water 5 times respectively, and the precipitate was finally dispersed in ethanol.

[0045] (6) Mix 1 mg of the microspheres washed in Step 5 and 0.2 ml (aqueous solution with a concentration of 25.4 mmol / L) of chloroauric acid (HAuCl 4 ) mixed in 10ml of ethanol and water mixed reagent (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com