Carbon nickel series olefin polymerization catalyst containing sulfur family elements as well as preparation and uses thereof

A technology of olefin polymerization and chalcogen elements, which is applied in the field of nickel-based olefin polymerization catalysts and its preparation, can solve the problems of air sensitivity, intolerance, and low catalytic activity of catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

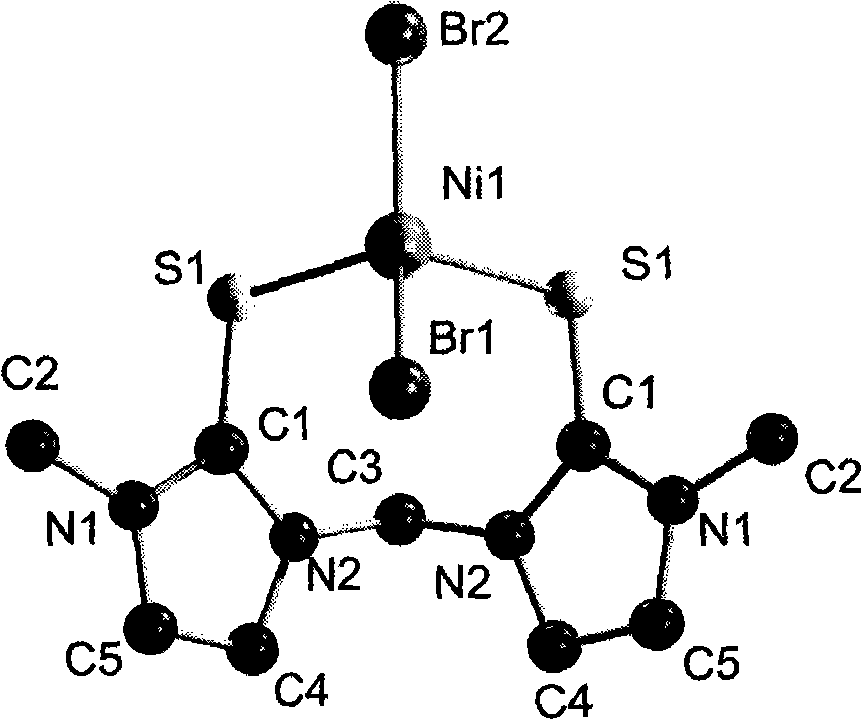

[0022] Embodiment 1: Preparation of ligand L1:

[0023] Under the protection of high-purity argon, 0.01mol 1,1-bis(1-methylimidazolium)methane bromide salt, 0.01mol potassium carbonate, 0.02mol sulfur powder (the ratio of the amount of the three substances is 1:1: 2), 60mL of methanol or toluene or tetrahydrofuran is placed in a 100ml reaction flask, refluxed for 24 hours, cooled to room temperature, removed solvent, CH 2 Cl 2 or CHCl 3 After washing and filtering, the solvent was removed to obtain 1.63 g of colorless solid powder with a yield of 68%.

Embodiment 2

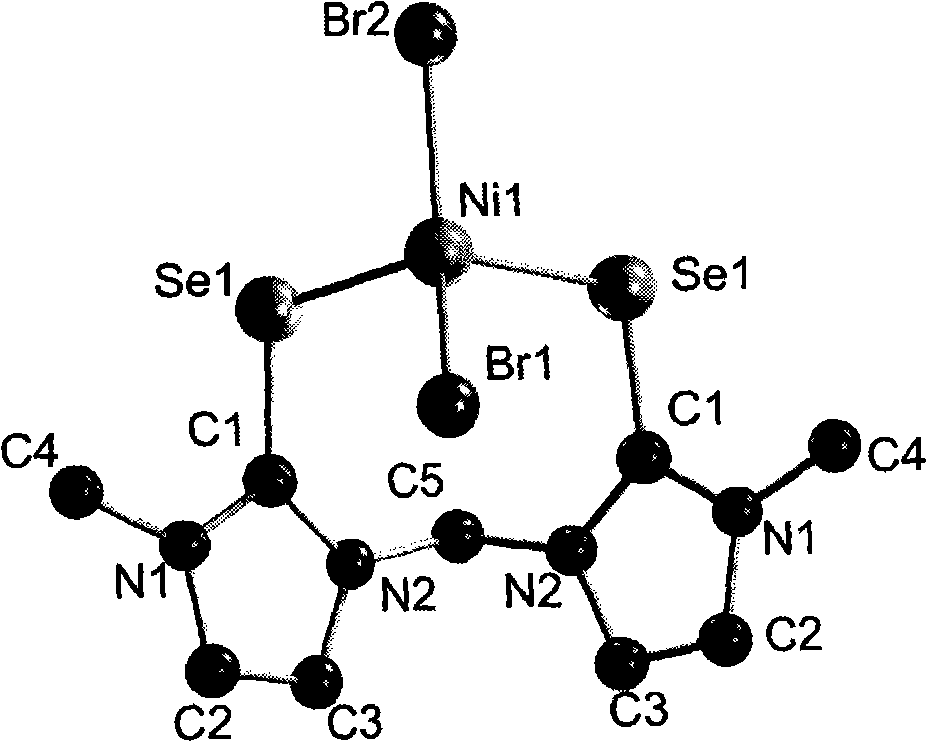

[0024] Embodiment 2: the preparation of ligand L2:

[0025] Under the protection of high-purity argon, with 0.01mol 1,1-bis(1-methylimidazolium) methane bromide salt, 0.01mol potassium carbonate, 0.02mol selenium powder (the ratio of the amount of the three substances is 1:1: 2), 60mL of methanol or toluene or tetrahydrofuran is placed in a 100ml reaction flask, refluxed for 24 hours, cooled to room temperature, removed solvent, CH 2 Cl 2 or CHCl 3 After washing and filtering, the solvent was removed to obtain 1.90 g of a colorless solid powder with a yield of 56%.

Embodiment 3

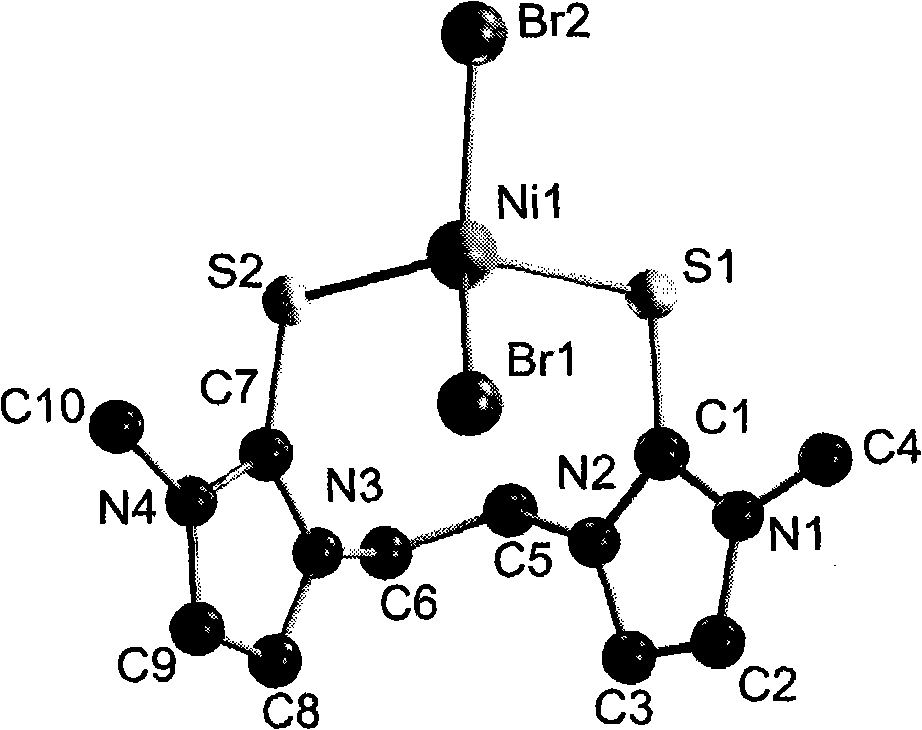

[0026] Embodiment 3: Preparation of ligand L3:

[0027] Under the protection of high-purity argon, 0.01mol 1,1-two (1-methylimidazolium) ethane bromide bromide, 0.01mol potassium carbonate, 0.02mol sulfur powder (the ratio of the amount of the three substances is 1:1 : 2), 60mL of methanol or toluene or tetrahydrofuran was placed in a 100ml reaction flask, refluxed for 24 hours, cooled to room temperature, solvent removed, CH 2 Cl 2 or CHCl 3 After washing and filtering, the solvent was removed to obtain 1.61 g of a colorless solid powder with a yield of 63%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com