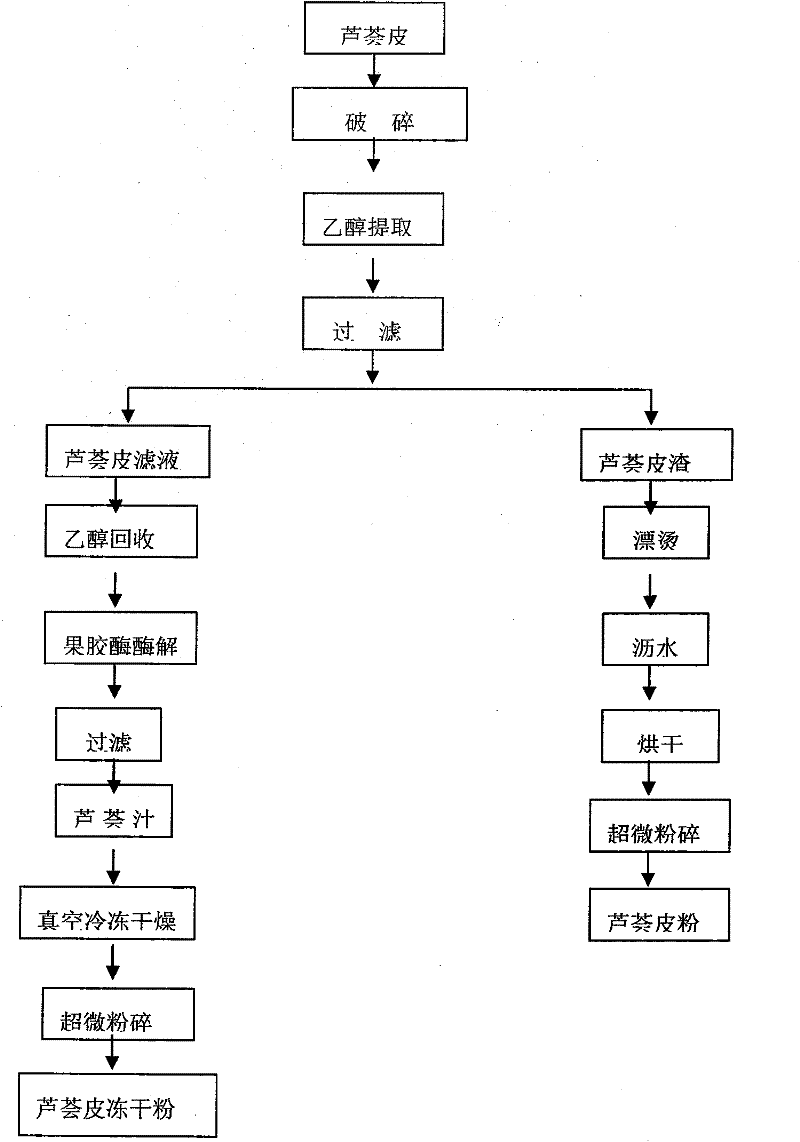

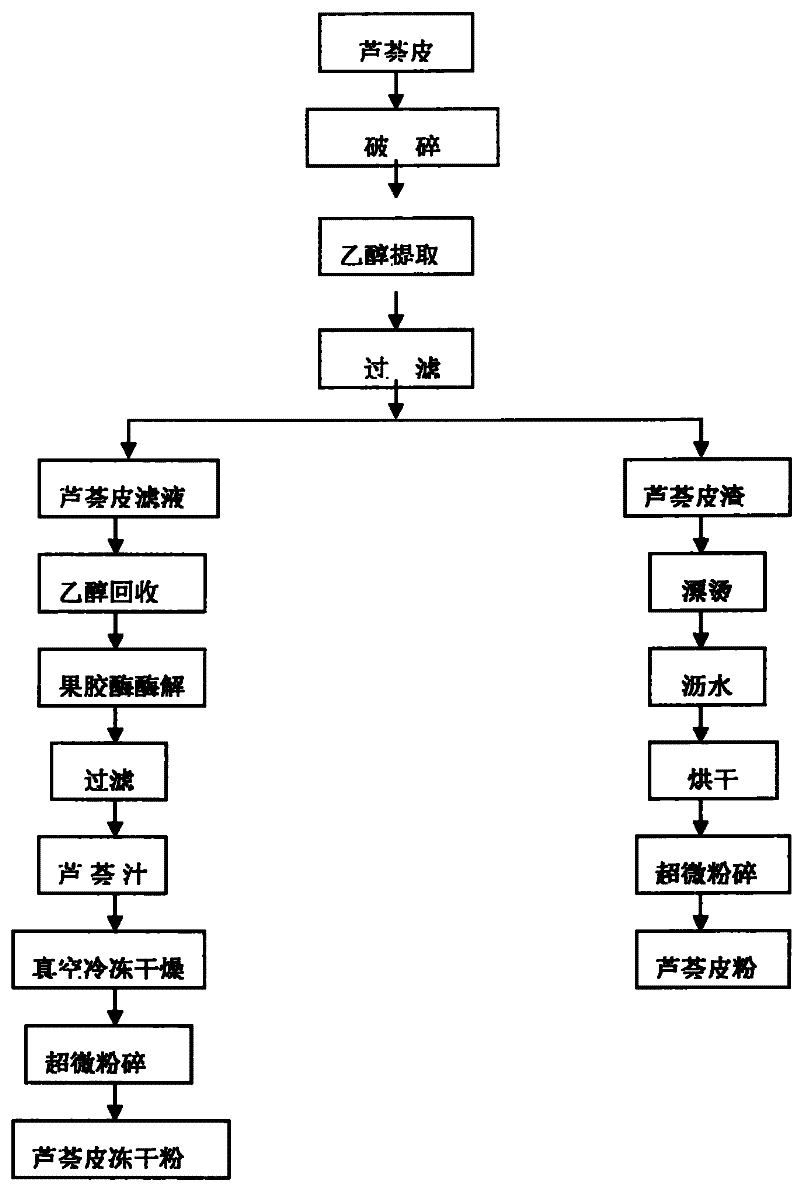

Comprehensive utilization aloe skin processing method

A processing method and technology of aloe bark, which is applied in the field of comprehensive utilization of aloe bark and aloe bark processing, can solve the problems of aloe plant utilization rate and even comprehensive utilization of resources, bad environment, waste of available resources, etc., and achieve comprehensive utilization rate High, reduce pollution, improve the effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A, after 1 ton of aloe bark is crushed into 1~10mm fragments with a crusher, 500 liters of concentration is added therein after being sent in the blender after being 70% ethanol, and under the stirring condition of 2600r / min, stir 2 minutes, for ethanol extraction;

[0019] B, filter A step gained mixture with the conventional method of prior art, obtain 914 kilograms of aloe bark filtrate and 580 kilograms of aloe bark respectively;

[0020] C. Add 914 kg of water to 914 kg of aloe bark filtrate and mix evenly, then heat the mixture to 50-55°C, reclaim ethanol, and return the obtained 499.9 liters of ethanol to step A for recycling. In the obtained 1328 kg of aloe bark juice , add 159.36 milliliters of pectinases, stir enzymolysis for 30 minutes, obtain 1320 kilograms of aloe juices by filtering with the conventional method of prior art;

[0021] D, carry out vacuum freeze-drying, ultra-low temperature pulverization with C step gained aloe juice with the conventional ...

Embodiment 2

[0024] A, after 1 ton of aloe bark is crushed into 1~10mm fragments with a crusher, 1000 liters of concentration is added therein after being sent in the blender after being 70% ethanol, and under the stirring condition of 2200r / min, stir 5 minutes, for ethanol extraction;

[0025] B, the mixture of A step is filtered with the conventional method of prior art, obtains aloe bark filtrate and aloe bark respectively;

[0026] C. After adding water of equal quality to the aloe bark filtrate and mixing evenly, the mixed solution is heated to 50-55°C, and the ethanol is recovered, and the obtained ethanol is returned to step A for recycling. In each ton of aloe bark solution obtained, add 100 Milliliter of pectinase, stirred and enzymolyzed for 40 minutes, then filtered with the conventional method of the prior art, got the filtrate to obtain aloe juice, and the filter residue was stand-by;

[0027] D, carry out vacuum freeze-drying, ultra-low temperature pulverization with the alo...

Embodiment 3

[0030] A, after 1 ton of aloe bark is crushed into 1~10mm fragments with a crusher, 750 liters of concentration is added therein after being sent in the mixer after being 70% ethanol, and under the stirring condition of 2400r / min, stir 3 minutes, for ethanol extraction;

[0031] B, the mixture of A step is filtered with the conventional method of prior art, obtains aloe bark filtrate and aloe bark respectively;

[0032] C. After adding water of equal quality to the aloe bark filtrate and mixing evenly, the mixed solution is heated to 50-55°C, and ethanol is recovered, and the obtained ethanol is returned to step A for recycling. In the obtained per ton of aloe bark solution, add 110 Milliliter of pectinase, stirred and enzymolyzed for 35 minutes, then filtered with the conventional method of the prior art, got the filtrate to obtain the aloe juice, and the filter residue was set aside;

[0033] D, carry out vacuum freeze-drying, ultra-low temperature pulverization with the al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com