Method for preparing nano-crystal with core-shell structure

A technology of core-shell structure and nanocrystals, which is applied in the field of synthesis of high-quality core-shell structure nanocrystals by a phosphorus-free method, can solve the problems of harsh reaction conditions, complicated preparation process, and high synthesis cost, and achieve simplified synthesis procedures, simple procedures, and convenient The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

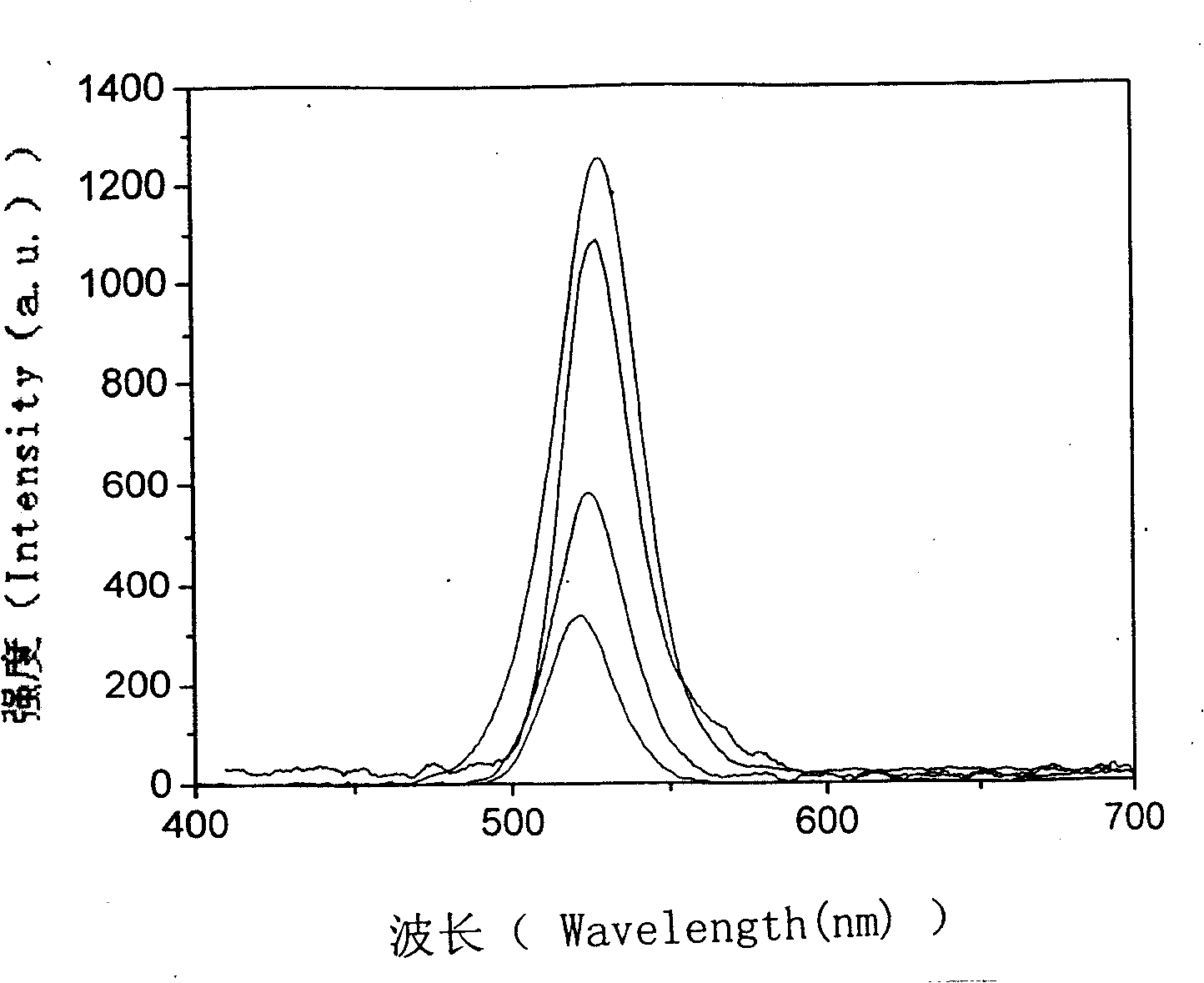

[0025] Synthesis of CdSe / ZnS core-shell nanocrystals. Take 0.4×10 -7 mol dot-like particles of CdSe nanocrystals (2.4nm in diameter) were injected into a 50mL three-path bottle, 3mL of liquid paraffin and 1g of octadecylamine were added, and the mixed solution was heated to 100°C under nitrogen for 30 minutes to exclude oxygen, and then heated to 140°C. ℃; heat and dissolve 1mmol ZnO and 3mmol oleic acid into 10ml liquid paraffin to obtain Zn(OA) 2 Solution, dissolve 1mmol sulfur in 10ml liquid paraffin to obtain a sulfur solution, mix 0.19ml zinc oleate and 0.19ml sulfur solution, add dropwise to a three-necked flask and raise the temperature to 160°C. After 10 minutes, add a mixed solution of 0.35ml zinc oleate solution and 0.35ml sulfur solution, raise the temperature to 200°C, and operate sequentially to obtain CdSe / ZnS nanocrystals with different thicknesses. Sampling and observation before each addition. In this process, core-shell structure nanocrystals with differen...

Embodiment 2

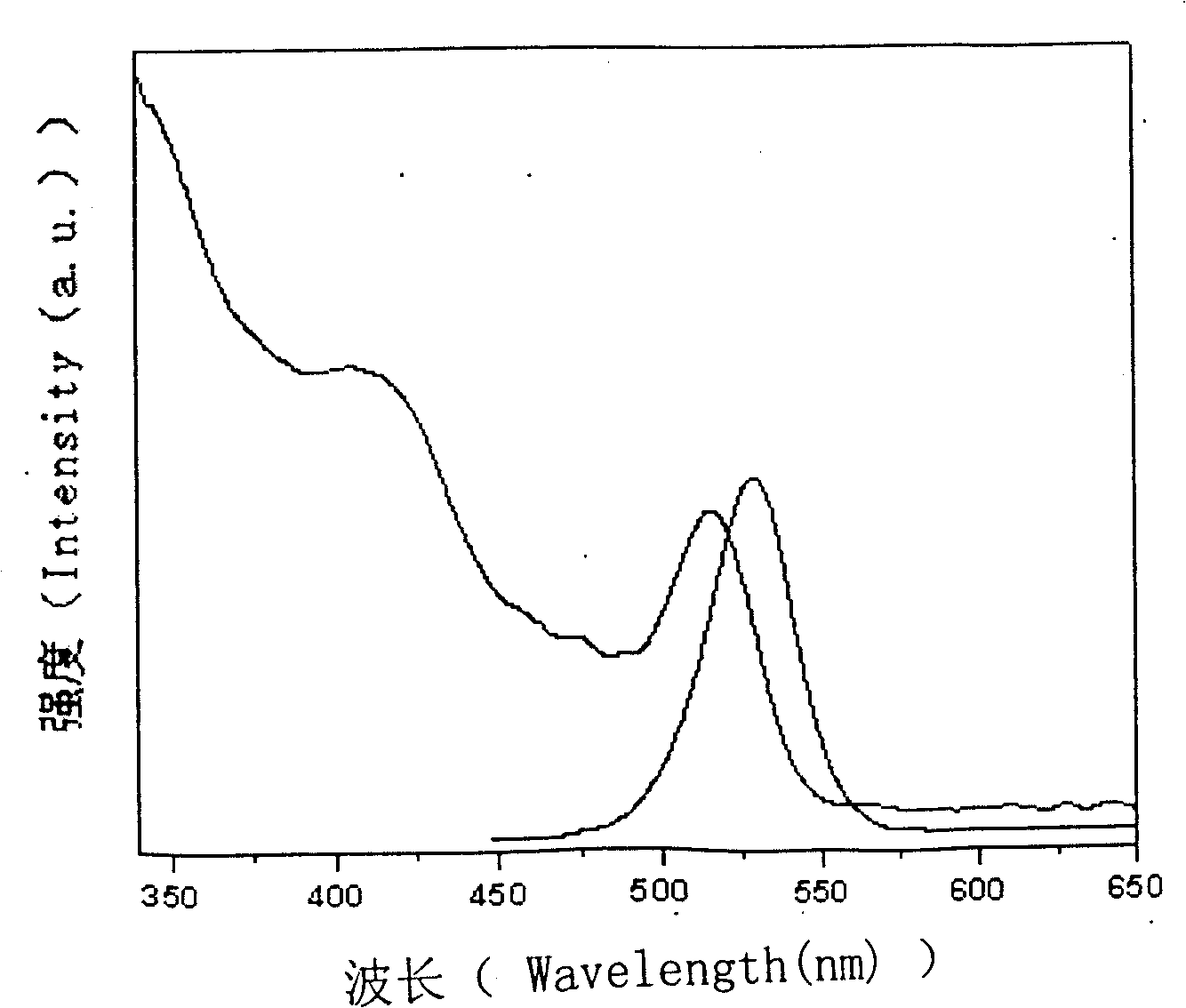

[0027] Synthesis of CdSe / CdS core-shell nanocrystals. Wherein, 1mmol cadmium oxide and 3mmol oleic acid are dissolved in 10ml liquid paraffin and thermally dissolved until the oleic acid cadmium solution obtained by clarification replaces the oleic acid zinc solution in the embodiment 1, and others are the same as the embodiment 1. The fluorescence absorption spectrum of CdSe / ZnS core-shell nanocrystals coated with three layers of CdS is shown in Figure 4 .

Embodiment 3

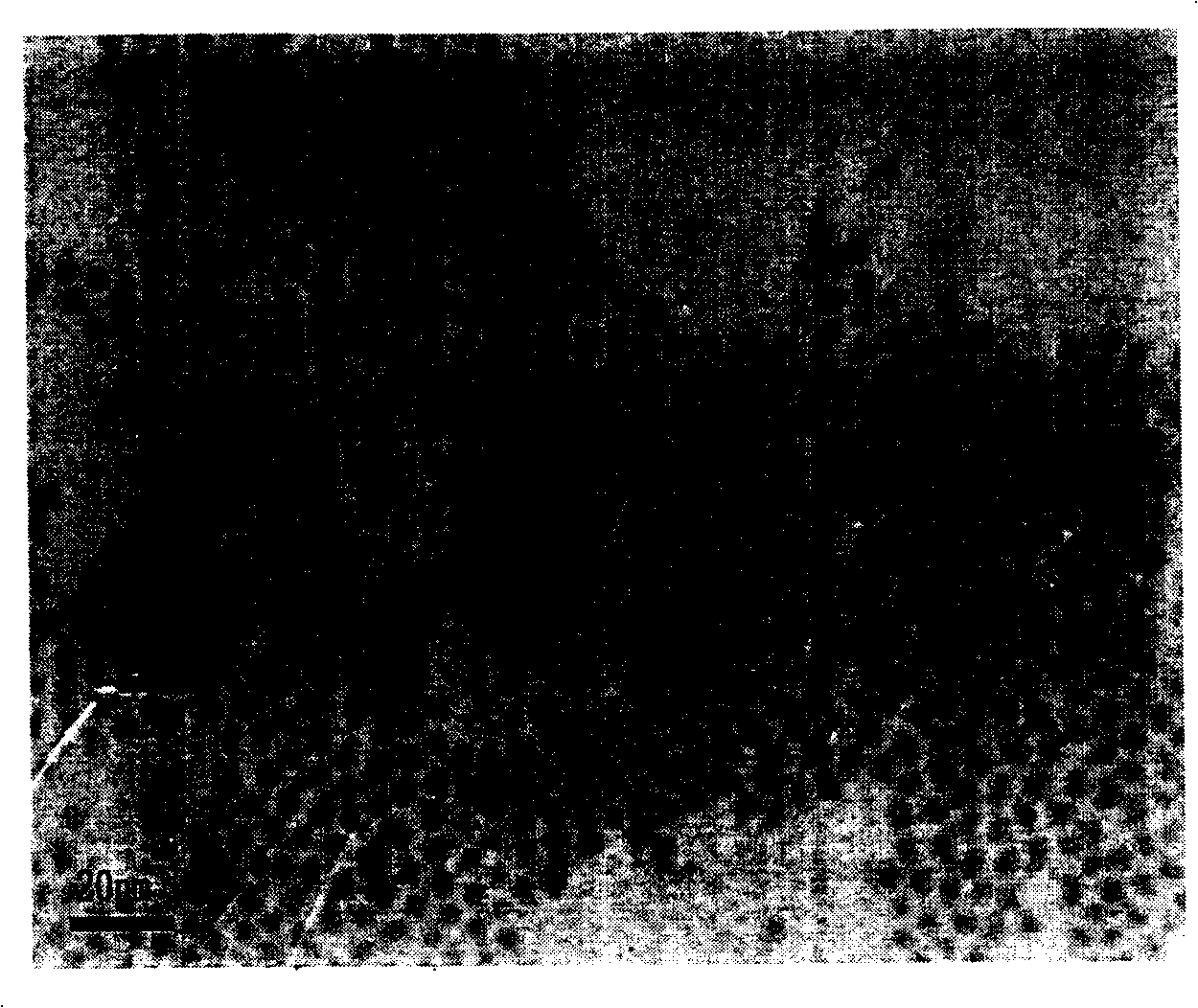

[0029] Synthesis of CdSe / CdS / ZnS core-shell nanocrystals. Take 0.21×10 -7 mol dot-like particles of CdSe nanocrystals (3.4nm in diameter) were injected into a 50mL three-path bottle, 3mL of liquid paraffin and 1g of octadecylamine were added, and the mixed solution was heated to 100°C under nitrogen for 30 minutes to exclude oxygen, and then heated to 160°C. ℃; heat and dissolve 1mmol CdO and 3mmol oleic acid into 10ml liquid paraffin to obtain Cd(OA) 2 Solution, heat and dissolve 1mmol ZnO and 3mmol oleic acid into 10ml liquid paraffin to obtain Zn(OA) 2Solution, dissolve 1mmol of sulfur in 10ml of liquid paraffin to obtain a sulfur solution, mix 0.67ml of cadmium oleate and 0.67ml of sulfur solution, add it dropwise into a three-necked flask and raise the temperature to 180°C to form a layer of CdS; After 10 minutes, add a mixed solution of 0.93ml zinc oleate solution and 0.93ml sulfur solution, raise the temperature to 200°C, and operate sequentially to obtain CdSe / CdS / Zn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com