A lithium ion battery cathode material composition, cathode, battery and method

A technology for lithium-ion batteries and negative electrode materials, which is applied in the direction of battery electrodes, battery pack components, non-aqueous electrolyte storage battery electrodes, etc., can solve the problems of shortened battery cycle life, unreported battery safety test results and high-current discharge performance, and unsatisfactory High-efficiency power battery requirements and other issues to achieve the effect of avoiding high temperature fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] According to the above description of the composition of the lithium-ion battery and the negative electrode material composition of the lithium-ion battery, the preparation method of the lithium-ion battery is specifically introduced below, and the process includes the following steps:

[0053] Step 1: Fabrication of the negative electrode sheet. According to the weight ratio, graphite, conductive agent, thickener, binder, and stabilizer are added to the solvent; the mixture is stirred, and the time, speed and temperature used for stirring are controlled to make negative electrode slurry within the expected viscosity range ; and coated on the current collector and dried; the dried pole piece is rolled into the required process thickness; according to the design requirements of the battery model, cut into the required size;

[0054] Step 2: Fabrication of the positive electrode sheet. According to the weight ratio, the active material, binder, and conductive agent are a...

Embodiment 1

[0073] Sodium carboxymethylcellulose (CMC) was dissolved in high-purity deionized water, and after stirring evenly, conductive graphite (KS15), mesophase carbon microspheres (CMB), fumed silica (SiO 2 ) and styrene-butadiene rubber (SBR), the weight composition of each component is CMB: CMC: KS15: SiO2 :SBR=93:1.5:1.5:2:2. The evenly stirred slurry was coated on a 20 μm thick copper foil current collector, vacuum-dried at 100° C., rolled, cut, and spot-welded with nickel lugs to obtain a negative electrode sheet.

[0074] The steps of preparation and liquid injection of the positive electrode sheet are the same as in Comparative Example 1.

Embodiment 2

[0076] Dissolve a certain amount of sodium carboxymethylcellulose (CMC) in high-purity deionized water, stir well, and then add conductive graphite (KS15), natural graphite (CMG) coated with mesocarbon microspheres (CMB), and Fumed silica (SiO 2 ) and styrene-butadiene rubber (SBR), the weight composition of each component is CMG: CMC: KS15: SiO 2 :SBR=90:1.5:1.5:5:2. The evenly stirred slurry was coated on a 20 μm thick copper foil current collector, vacuum-dried at 100° C., rolled, cut, and spot-welded with nickel lugs to obtain a negative electrode sheet.

[0077] The steps of preparation and liquid injection of the positive electrode sheet are the same as in Comparative Example 1.

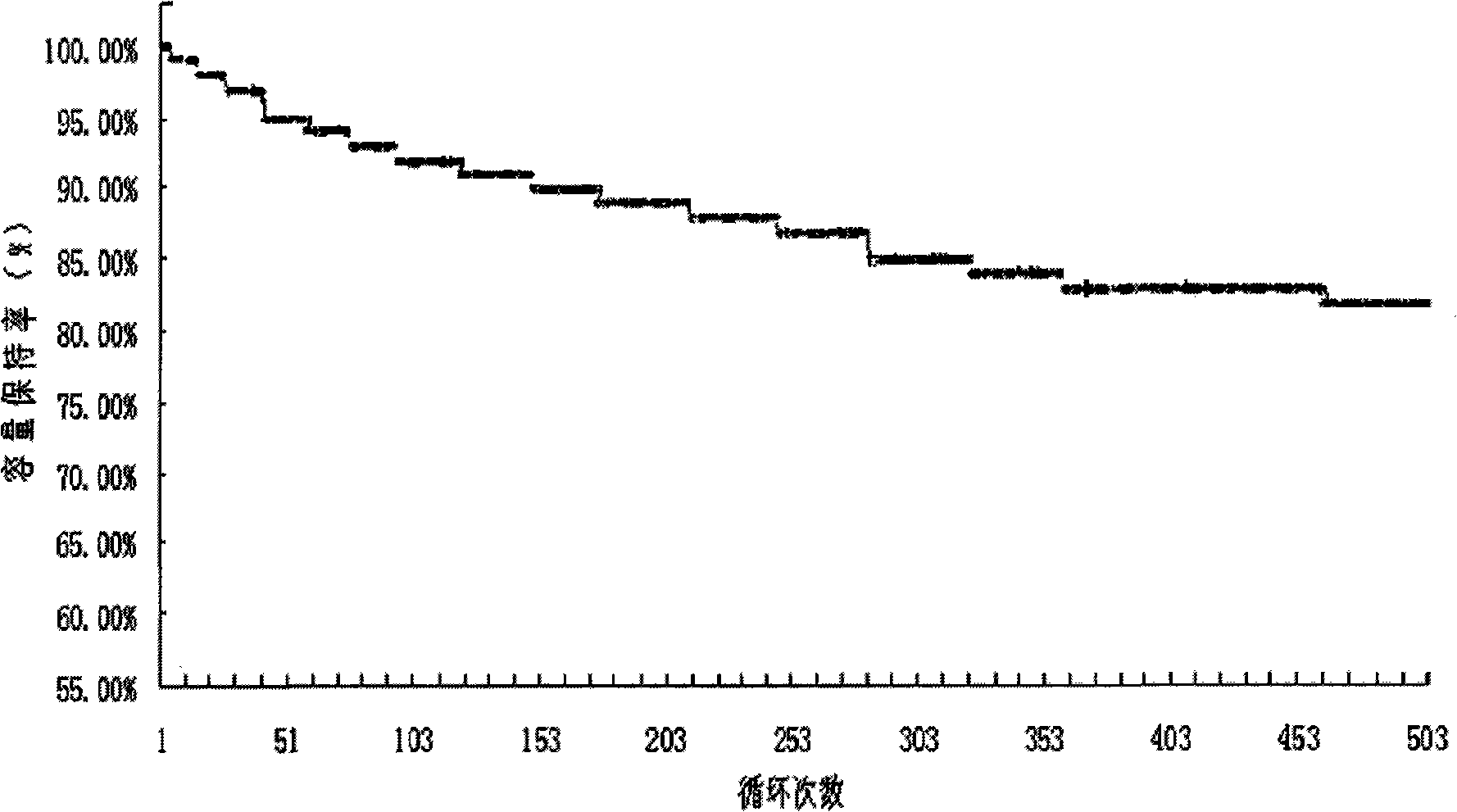

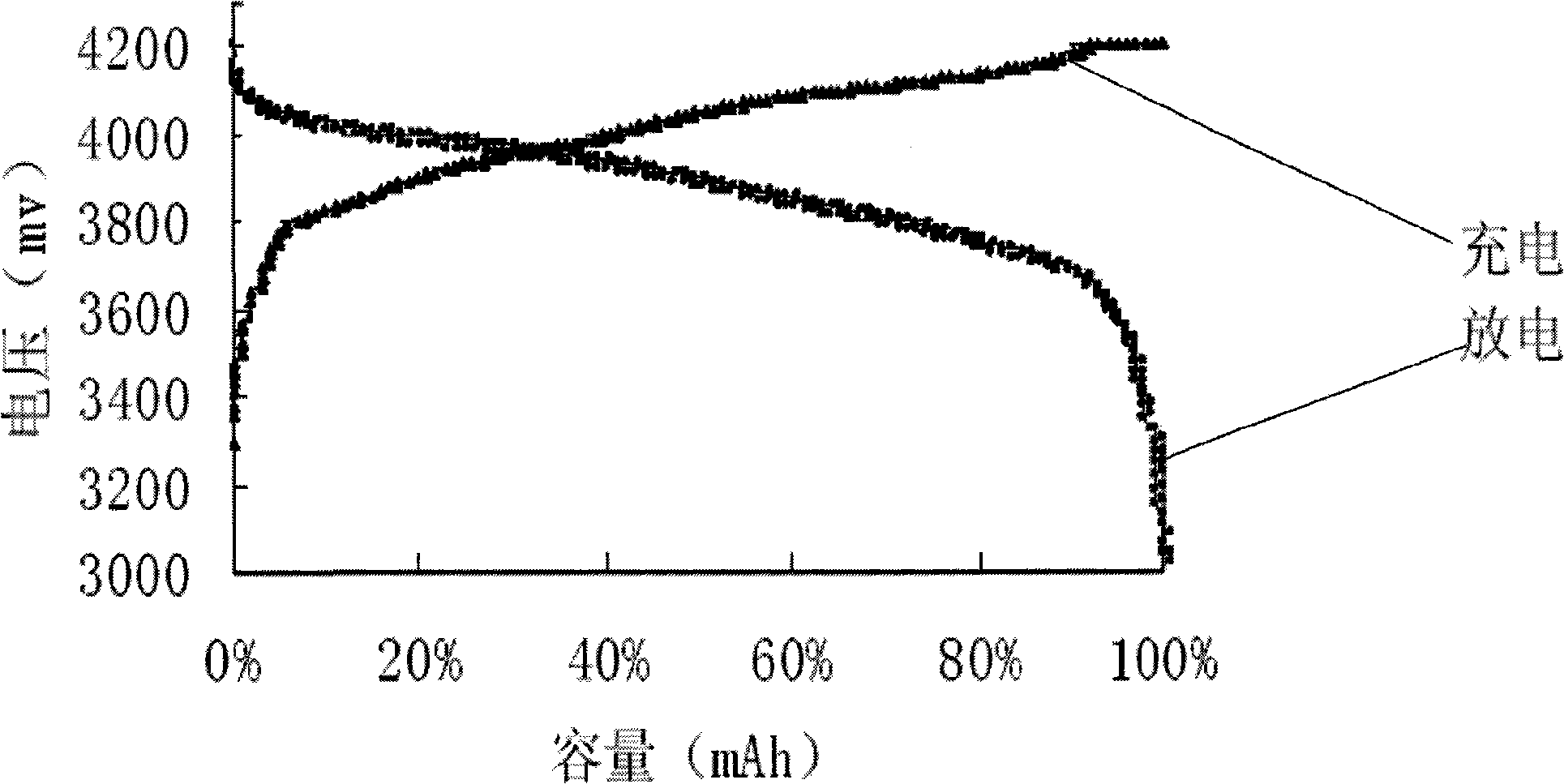

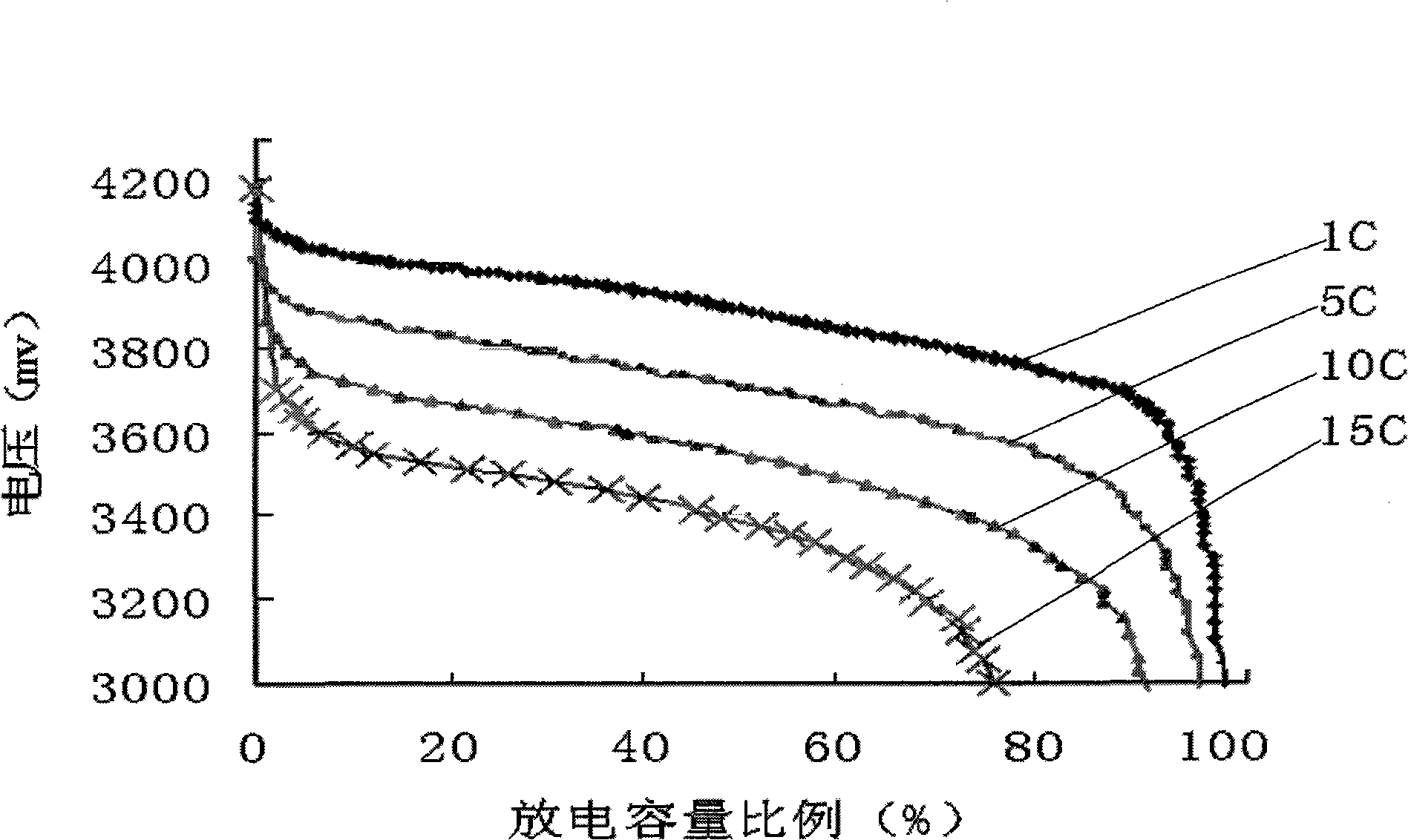

[0078] The beneficial effects of the technical solution of the present invention will be described below through corresponding test experiments.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com