Preparation of ultrafine powder auricularia nutrition noodle

A fungus powder and ultra-fine technology, applied in food preparation, dough processing, baking and other directions, can solve the problems of no plasticity and extensibility of fungus powder, affecting the quality of noodles, reducing dough strength, etc. Improved bioavailability and good connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Materials

[0022] Special flour: the wet gluten content is about 33%, the gluten quality of the flour is required to be relatively high, so as to avoid affecting the gluten quantity, elasticity and extensibility of the noodles due to the fiber brought in by the fungus;

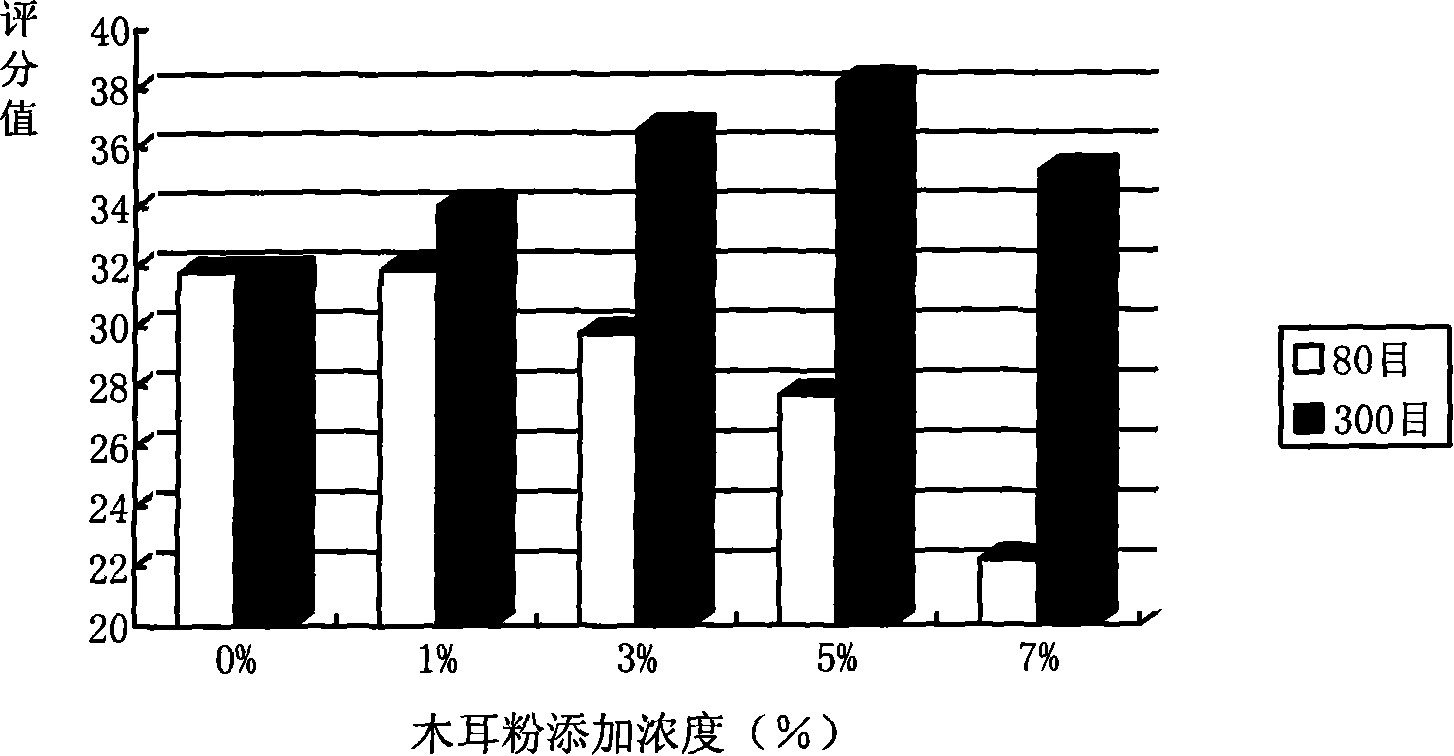

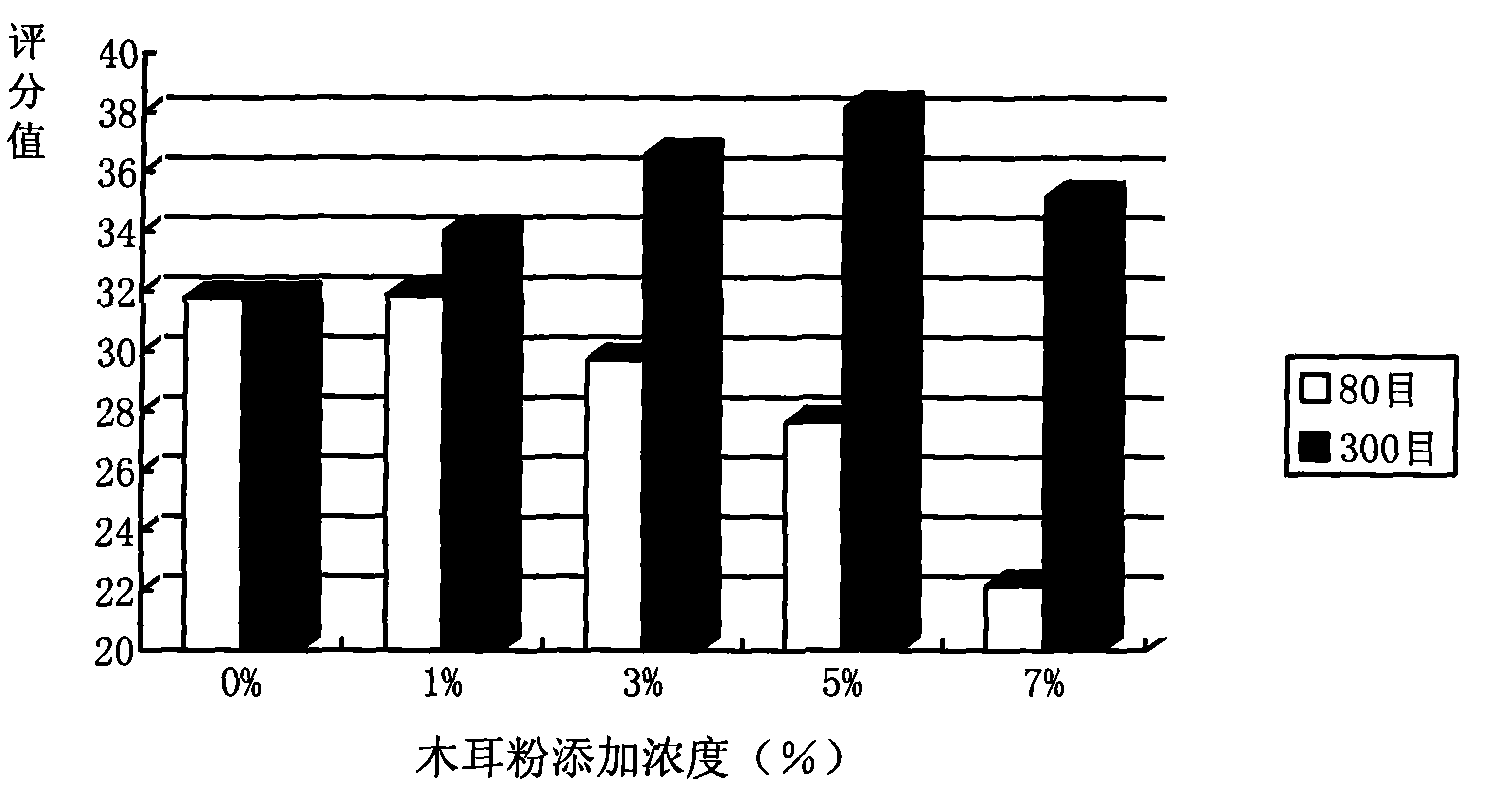

[0023] Fungus powder: 80 mesh ordinary coarse powder and 300 mesh superfine fungus powder;

[0024] Sodium alginate: as a quality improver.

[0025] 2. Instrument

[0026] Bailey powder machine, small noodle machine, electronic balance, small noodle grinder

[0027] 3 methods

[0028] 3.1 Process flow

[0029] Preparation of superfine powder of fungus → kneading noodles → ripening → pressing, cutting into strips → drying

[0030] 3.2 Operation points

[0031] Preparation of 80-mesh common fungus powder: vacuum-dry the fungus until the water content is below 6%, and pulverize in a small grinder to obtain 80-mesh common fungus powder.

[0032] Preparation of 300-mesh superfine fungus powder: th...

Embodiment 2

[0037] Embodiment 2: The difference from Embodiment 1 is that in 3.2 Operational Points:

[0038] Preparation of 300-mesh fungus ultrafine powder: vacuum-dry the fungus until the water content is below 10%, and pulverize it in an ultrafine pulverizer for 6 minutes to obtain superfine fungus powder.

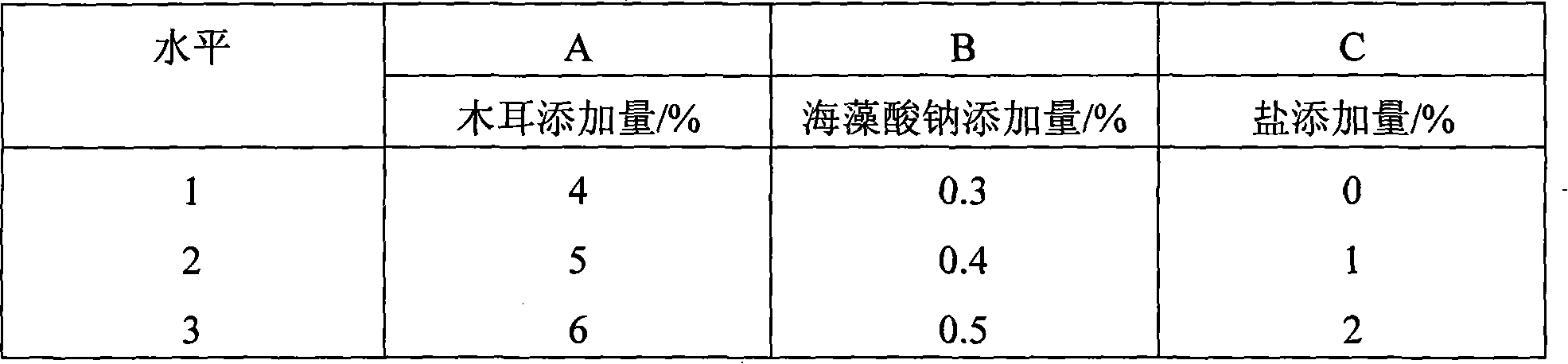

[0039] Kneading noodles: Melt 15g of fungus powder, 1.2g of sodium alginate and 6g of table salt with 33% of the weight of flour to form a slurry. Stir evenly and place it for 10 minutes to allow the fungus powder to fully absorb moisture and expand to form a stable slurry. Add to 300g Flour neutralizes the dough, the dough mixing time is 18min, and the dough temperature is 25°C.

[0040] Maturing: Let the reconciled dough stand for 30 minutes to allow the dough to fully absorb water to form a gluten network structure, and keep the dough temperature at 25°C.

[0041] Pressing and cutting strips: Repeatedly press the matured dough on a small noodle press to form a fine-textured, m...

Embodiment 3

[0042] Embodiment 3: The difference from Embodiment 1 is in 3.2 Operational Points:

[0043] Preparation of 300-mesh fungus ultrafine powder: vacuum-dry the fungus until the water content is below 10%, and pulverize it in an ultrafine pulverizer for 10 minutes to obtain superfine fungus powder.

[0044] Kneading noodles: Melt 30g of fungus powder, 1.8g of sodium alginate and 12g of table salt with 35% of the weight of flour to form a slurry. Stir evenly and place it for 15 minutes to allow the fungus powder to fully absorb moisture and expand to form a stable slurry. Add to 300g The flour is neutralized, the dough time is 20min, and the dough temperature is 30°C.

[0045] Maturing: Let the reconciled dough stand for 40 minutes to make the dough fully absorb water and form a gluten network structure, and keep the dough temperature at 30°C.

[0046] Pressing and cutting strips: Repeatedly press the matured dough on a small noodle press to form a fine-textured, mutually cohesive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com