Composite aluminium-magnesium-silicate thermal insulating material and preparation technique

A thermal insulation material and a technology of magnesium aluminum silicate, which is applied in the field of preparation technology of composite magnesium aluminum silicate thermal insulation materials, can solve problems such as complex production process, and achieve the effects of simple production process, scientific and reasonable formula, and good thermal insulation performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Composite magnesium aluminum silicate thermal insulation material, which includes the following components by weight: 20 parts of bentonite, 15 parts of attapulgite, 10 parts of sepiolite, 1 part of titanium oxide, 500 parts of water, 30 parts of brucite, and 1 part of ceramic fiber , 2 parts of aluminum dihydrogen phosphate, 8 parts of sodium sulfosuccinate, 4 parts of sodium silicate, 1 part of polyvinyl alcohol, 1 part of carboxymethyl cellulose, and 10 parts of perlite.

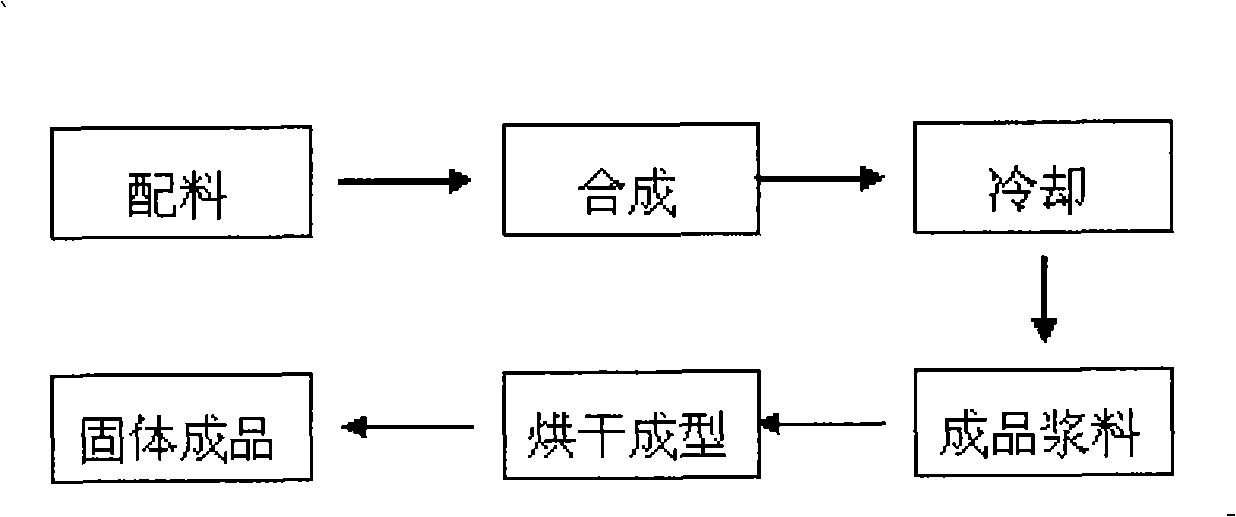

[0017] The composite magnesium aluminum silicate thermal insulation material is synthesized according to the following steps: ①. First, add bentonite, attapulgite, sepiolite, brucite, ceramic fiber, and water in the above-mentioned materials by weight into the synthesis kettle; then add the above-mentioned weight parts Titanium oxide, aluminum dihydrogen phosphate, sodium silicate, polyvinyl alcohol, carboxymethyl cellulose in the material; finally add perlite and stir while adding, the synthesis te...

Embodiment 2

[0019] Composite magnesium aluminum silicate thermal insulation material, which includes the following components by weight: 40 parts of bentonite, 40 parts of attapulgite, 40 parts of sepiolite, 3 parts of titanium oxide, 800 parts of water, 50 parts of brucite, and 3 parts of ceramic fiber , 5 parts of aluminum dihydrogen phosphate, 15 parts of sodium sulfosuccinate, 8 parts of sodium silicate, 3 parts of polyvinyl alcohol, 4 parts of carboxymethyl cellulose, and 15 parts of perlite.

[0020] The composite magnesium aluminum silicate thermal insulation material is synthesized according to the following steps: ①. First, add bentonite, attapulgite, sepiolite, brucite, ceramic fiber, and water in the above-mentioned materials by weight into the synthesis kettle; then add the above-mentioned weight parts Titanium oxide, aluminum dihydrogen phosphate, sodium silicate, polyvinyl alcohol, carboxymethyl cellulose in the material; finally add perlite and stir while adding, the synthes...

Embodiment 3

[0022] Composite magnesium aluminum silicate thermal insulation material, which includes the following components by weight: 30 parts of bentonite, 30 parts of attapulgite, 25 parts of sepiolite, 2 parts of titanium oxide, 600 parts of water, 40 parts of brucite, and 2 parts of ceramic fiber , 3 parts of aluminum dihydrogen phosphate, 12 parts of sodium sulfosuccinate, 6 parts of sodium silicate, 2 parts of polyvinyl alcohol, 2 parts of carboxymethyl cellulose, and 12 parts of perlite.

[0023] The composite magnesium aluminum silicate thermal insulation material is synthesized according to the following steps: ①. First, add bentonite, attapulgite, sepiolite, brucite, ceramic fiber, and water in the above-mentioned materials by weight into the synthesis kettle; then add the above-mentioned weight parts Titanium oxide, aluminum dihydrogen phosphate, sodium silicate, polyvinyl alcohol, carboxymethyl cellulose in the material; finally add perlite and stir while adding, the synthes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com