Device for removing volatile organic matter and generating hydrogen with non-equilibrium plasma

A volatile organic compound and plasma technology, which is applied in the field of environmental technology and waste gas recycling, can solve the problems of little research on pollutants, high energy consumption, and no consideration of recycling, avoiding the formation of high-temperature arcs and reducing energy consumption. , the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

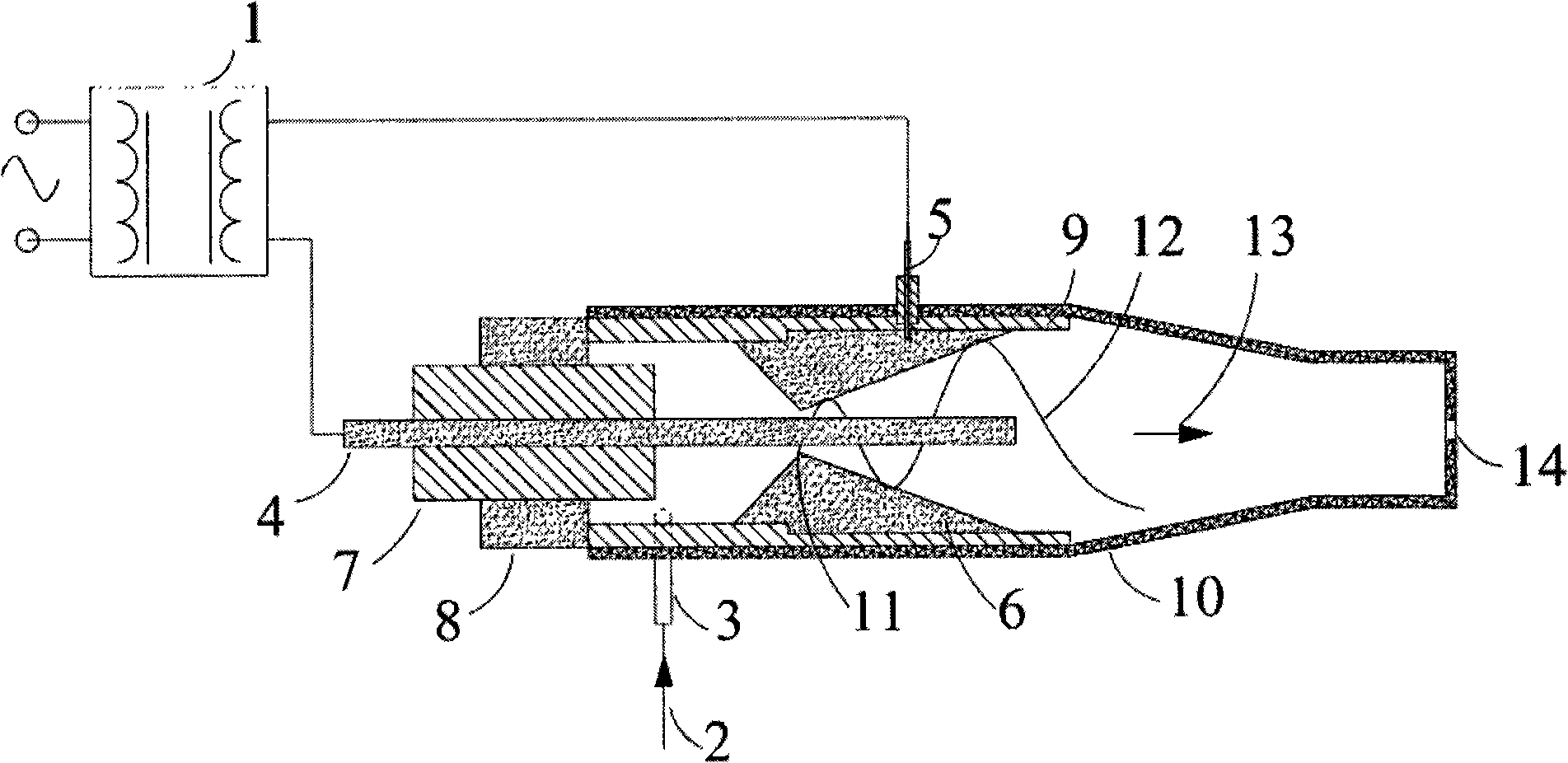

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0018] Referring to the accompanying drawings, the material used to make the cylindrical center electrode 4 and the outer electrode 6 of the Laval nozzle is brass; the length of the center electrode is 280 mm, and the diameter is 8 mm; the length of the outer electrode is 110 mm, the outer diameter is 68 mm, and the minimum distance between the two electrodes is 3 mm; Sexual organic waste gas 2 contains 5000ppm toluene, with a flow rate of 20m 3 / h, the output voltage of the AC high-voltage power supply 1 is controlled at 10kV; at this time, the toluene elimination rate is over 90%, the energy utilization rate is about 1200g / kWh, and the hydrogen concentration detected in the exhaust gas is about 1000ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com