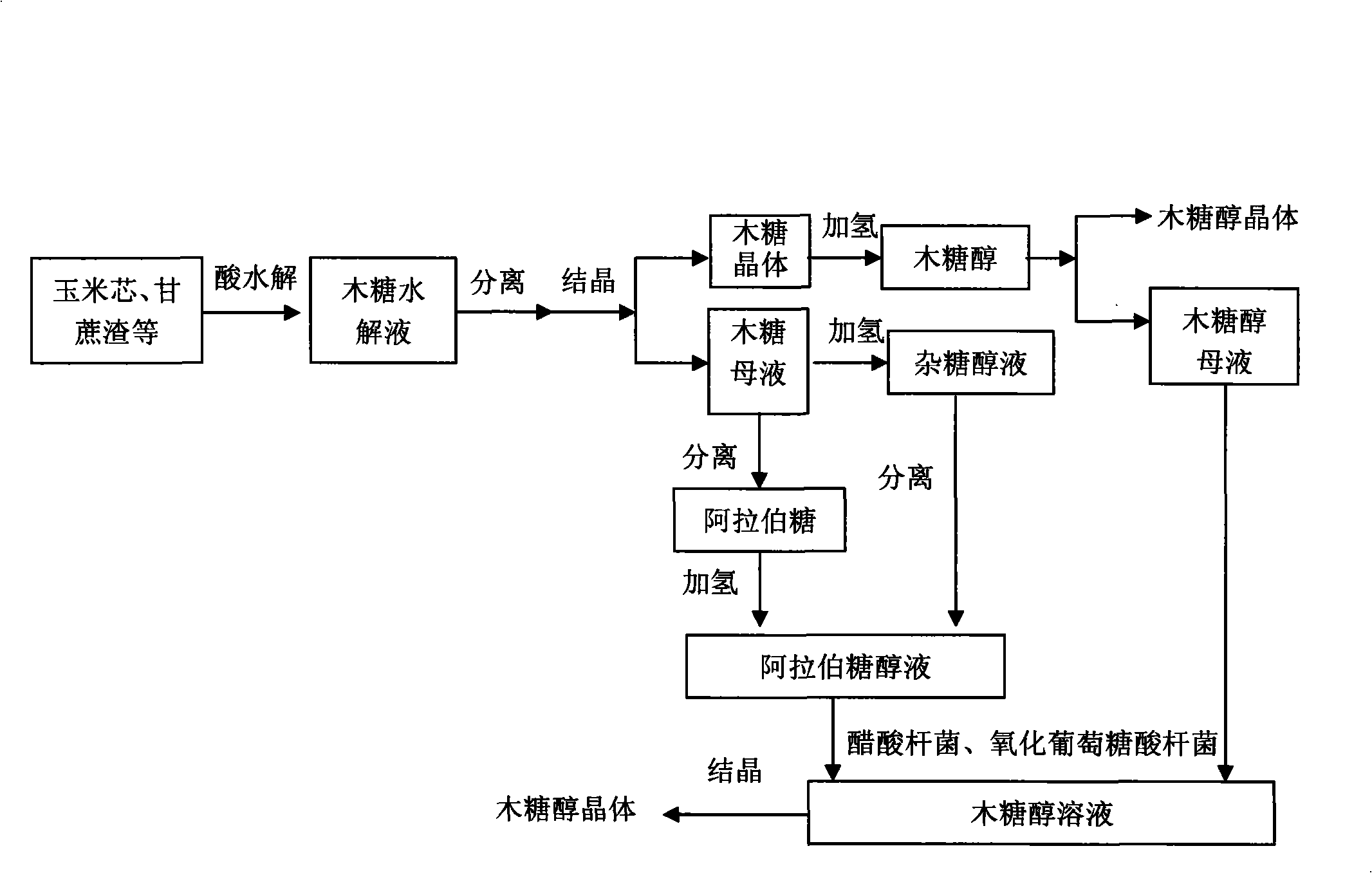

Process for producing eutrit by waste xylose mother liquor or eutrit mother liquor in production process of eutrit

A technology of xylose mother liquor and xylitol, which is applied in the field of xylitol production, can solve the problems of reducing the economic benefits of xylose, and achieve the effects of improving production economic benefits, simple and reasonable process, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

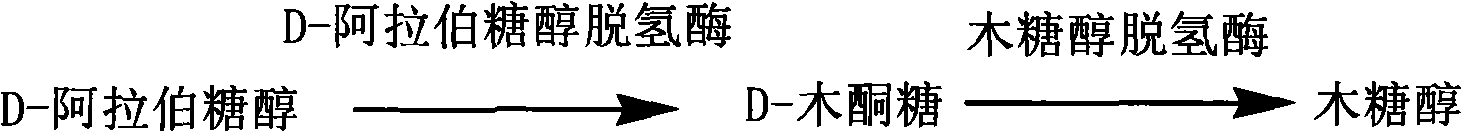

Method used

Image

Examples

example 1

[0027] The xylose mother liquor (the sugar refractive concentration is about 63%, which contains 22% arabinose, 50% xylose, 6% galactose and 15% glucose) utilizes 732Na + The separation conditions are as follows: separation temperature 70°C, system pressure 1.1MPa, feed flow rate 1L / h, elution water flow rate 3.5L / h, separate arabinose from the xylose mother liquor, and obtain a purity of 95% arabinose liquid. Add this arabinose solution into the hydrogenation reactor, react until the reducing sugar content is less than 0.1%, and obtain the D-arabitol solution with a refractive concentration of 50% and a D-arabitol content of about 94%, ready for use .

[0028] Gluconobacter oxydans ATCC621 was inoculated in a 250mL Erlenmeyer flask containing 50mL of bacterial culture medium A, cultured on a rotary shaker at 30°C and 220rpm for 72h, the cells were collected by centrifugation, and washed once with 0.1M phosphate buffer before use. The composition of bacterial medium A is: 50...

example 2

[0032] Gluconobacter oxydans ATCC621 was inoculated in a 250mL Erlenmeyer flask containing 50mL bacterial culture medium B, and cultured on a rotary shaker at 37°C and 220rpm for 30h. The cells were collected by centrifugation and washed once with 0.1M phosphate buffer before use. The composition of bacterial medium B is: 30g / L glucose, 5g / L yeast extract, 10g / L peptone, 20g / L D-arabinitol.

[0033] The cells after washing are inserted into 50mL sugar refraction concentration as 10% xylitol crystallization mother liquor with the addition amount of 15% (W / V), and wherein xylitol content is 60%, and arabitol content is 30% (D - the concentration of arabitol is 30g / L), and the transformation is carried out on a rotary shaker at 25° C. and 220 rpm for 35 hours. At the end of the transformation, the concentration of xylitol in the transformation liquid is 88 g / L.

[0034] Centrifuge the transformed liquid to obtain 47 mL of supernatant, add 0.94 g of activated carbon, adjust the pH...

example 3

[0036]Acetobacter was inoculated in a 250mL Erlenmeyer flask containing 50mL bacterial culture medium C, cultured on a rotary shaker at 25°C and 220rpm for 50h, the cells were collected by centrifugation, washed once with 0.1M phosphate buffer and set aside for use. The composition of bacterial culture medium C is: 10g / L glucose, 20g / L yeast extract, 8g / L peptone, 30g / L D-arabinitol.

[0037] Mix 5 mL of the D-arabitol solution prepared in Example 1 with 10 mL of the xylitol crystallization mother liquor with a sugar refractive concentration of 20% (wherein the xylitol content is 60%, and the arabitol content is 30%), and add 0.5 g of glucose was distilled to 50 ml as a transformation solution (the content of D-arabitol was 32 g / L).

[0038] The washed cells were added into 50 mL of the above-mentioned transformation solution at an addition amount of 5% (W / V), and transformed at 37° C. and 220 rpm on a rotary shaker for 20 hours. At the end of the transformation, the concentra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com