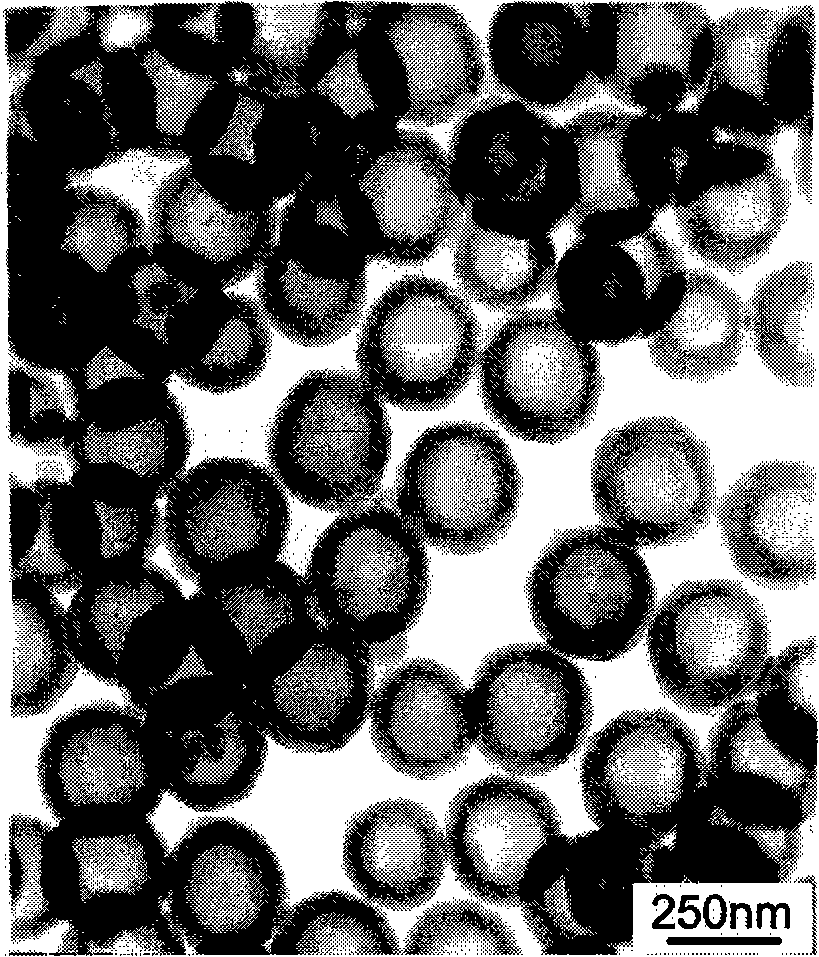

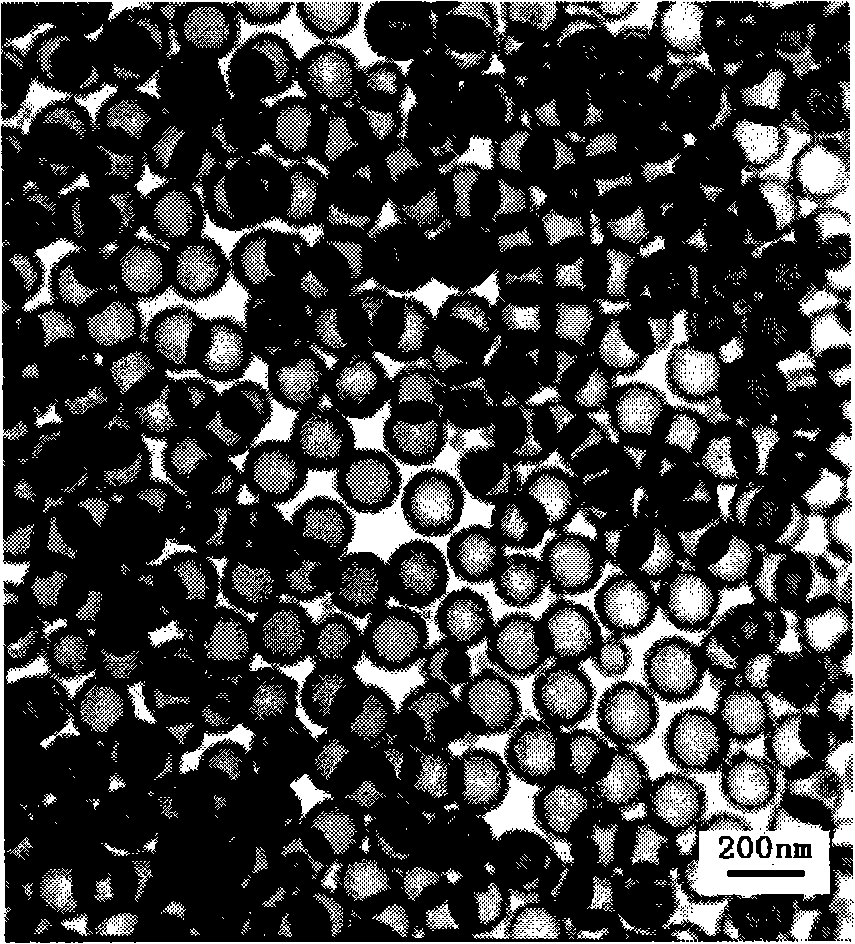

Functional hollow earth silicon microballoons and method for preparing same

A silica and functionalized technology, applied in the field of composite materials and functional materials, can solve problems such as limited application, and achieve the effects of simple preparation, low density and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

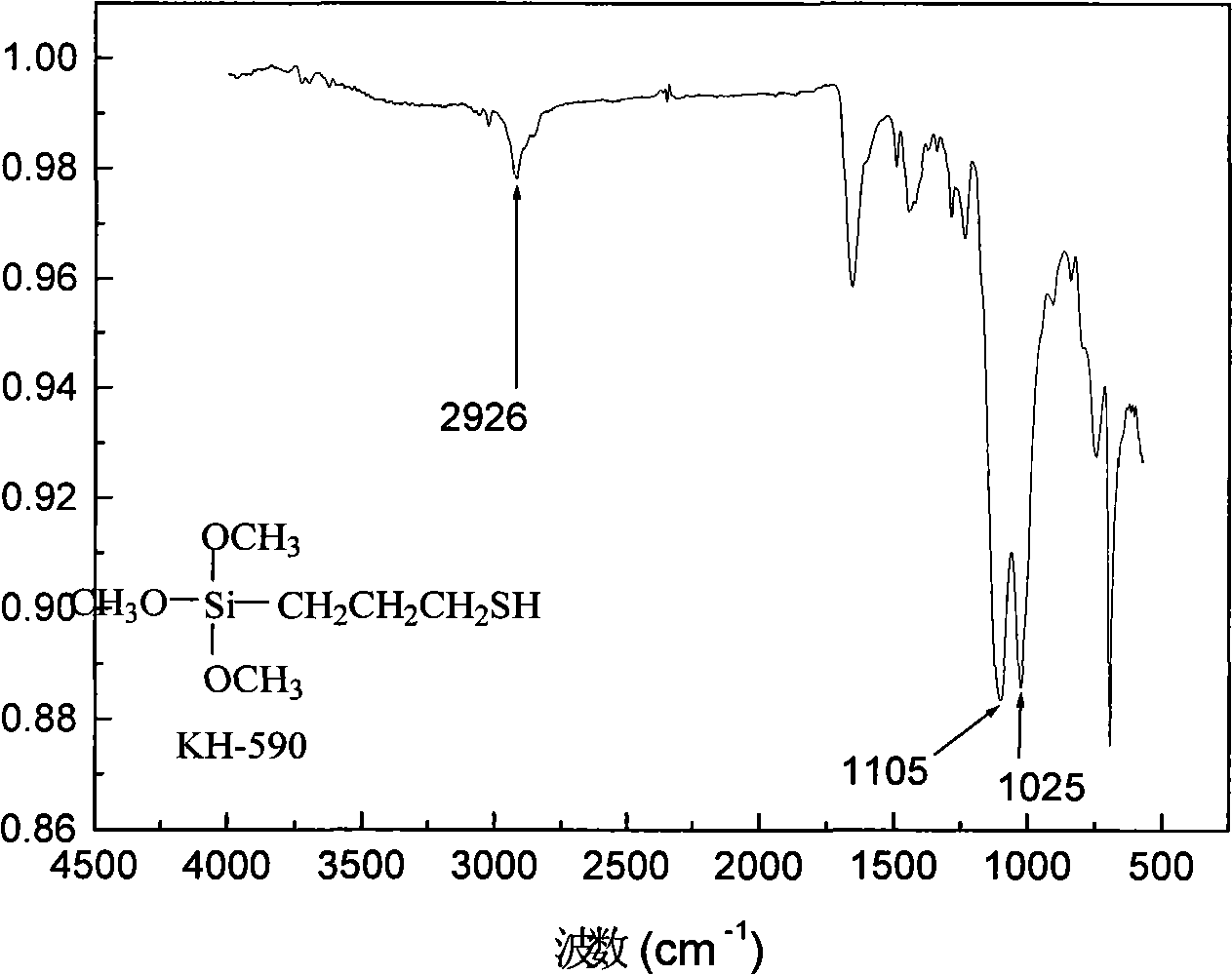

Embodiment 1

[0037] The ratio of raw materials used is as follows:

[0038] 100 parts (weight) of positively charged polystyrene microspheres on the surface

[0039] Ammonia (28wt.%) 80 parts (weight)

[0040] Vinyl triethoxysilane 50 parts (weight)

[0041] 400 parts (weight) of ethanol

[0042] 50 parts of deionized water (by weight)

[0043] According to the proportions of the above components, the polystyrene microspheres with positive charges on the surface were ultrasonically dispersed in the mixed medium of ethanol and water for 0.5 hours to obtain sample a. In a four-neck flask with nitrogen gas, heat to 50°C, then pour ammonia water into the reactor and stir for 5-15 minutes, then quickly pour vinyltriethoxysilane into the reaction container, and continue to stir the reaction 5-8 hours. Stop heating afterwards, after cooling to room temperature, carry out centrifugation, and wash 3-4 times with ethanol and water. This is vinyl-functionalized hollow silica microspheres.

Embodiment 2

[0045] The ratio of raw materials used is as follows:

[0046] 100 parts (weight) of positively charged polystyrene microspheres on the surface

[0047] Ammonia (28wt.%) 80 parts (weight)

[0048] Vinyl trimethoxysilane 20 parts (weight)

[0049] 400 parts (weight) of ethanol

[0050] 50 parts of deionized water (by weight)

[0051] According to the proportion of the above components, the polystyrene microspheres with positive charges on the surface were ultrasonically dispersed in the mixed medium of ethanol and water for 0.5 hours to obtain sample a. At this time, the sample a was heated to 60°C, and ammonia water Put it into the reactor and stir for 5-15 minutes, then quickly pour vinyltrimethoxysilane into the reaction vessel, and continue to stir and react for 5-8 hours. Stop heating afterwards, after cooling to room temperature, carry out centrifugation, and wash 3-4 times with ethanol and water. At this point, vinyl-functionalized hollow silica microspheres are obt...

Embodiment 3

[0053] The ratio of raw materials used is as follows:

[0054] 100 parts (weight) of positively charged polystyrene microspheres on the surface

[0055] Sodium hydroxide solution (0.01mol / L) 2 parts (weight)

[0056] 20 parts (weight) of γ-(methacryloyloxy)propyltrimethoxysilane

[0057] Methanol 400 parts (weight)

[0058]50 parts of deionized water (by weight)

[0059] According to the proportion of the above components, the positively charged polystyrene microspheres on the surface were ultrasonically dispersed in the mixed medium of methanol and water for 0.5 hours to obtain sample a. At this time, the sample a was heated to 40°C, and the hydrogen Pour the sodium solution into the reactor and stir for 5-15 minutes, then quickly pour γ-(methacryloyloxy)propyltrimethoxysilane into the reaction vessel, and continue to stir and react for 5-8 hours. Stop heating afterwards, after cooling to room temperature, carry out centrifugation, and wash 3-4 times with ethanol and wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com