Biological desulphurization process for waste and old rubber

A biological desulfurization and waste rubber technology, which is applied in the field of microbial desulfurization of waste rubber, can solve the problems that the desulfurization efficiency depends on the survival amount of sulfur-loving microorganisms, the desulfurization process is complicated, and the desulfurization effect is affected, achieving good physical and mechanical properties, and the desulfurization process is simple. The effect of simple and convenient cultivation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

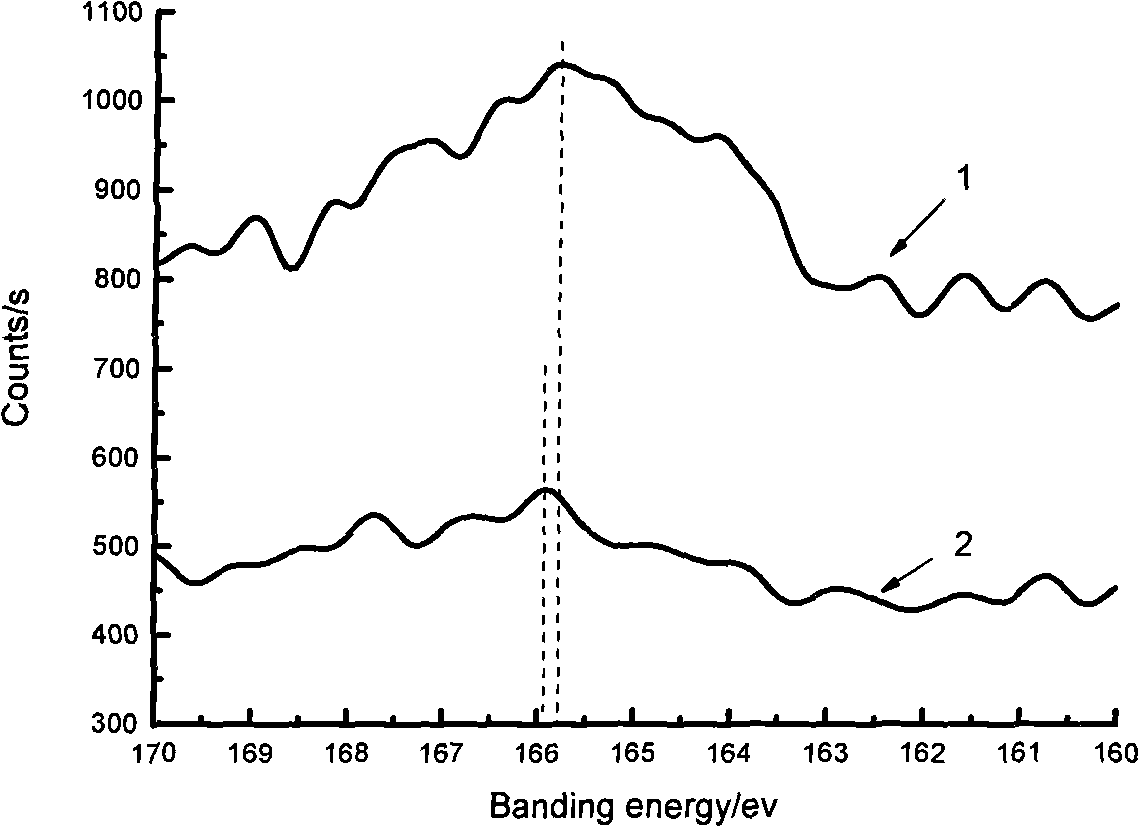

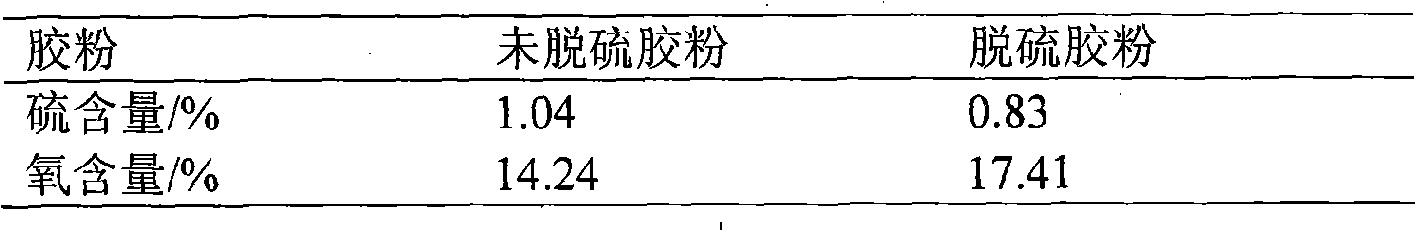

[0020] Take 1.2g of hexadecyltrimethylammonium bromide in a 500ml three-necked flask, add 200ml of water, control the temperature of the water bath at 40°C, and set the stirring speed at 1300r / min to form hexadecyltrimethylammonium bromide Aqueous amine solution. Then, 100 ml of cyclohexane was added dropwise to the aqueous solution of cetyltrimethylammonium bromide, and stirred for 20 minutes to form an emulsion. Add 20 g of natural rubber powder prepared by a known sulfur vulcanization method into the prepared emulsion, start stirring, control the stirring speed at 300 r / min, and swell for 40 min. Then add 0.2g of glutathione into the rubber powder emulsion and react for 2h. Then suction filter, wash, and dry to obtain desulfurized rubber powder. The obtained desulfurized rubber powder is masticated on an open mill for 12 minutes. The sulfur content and oxygen content on the surface of the rubber powder in this example before and after desulfurization are shown in Table 1,...

Embodiment 2

[0025] Example 2: Take 0.2g of cetyltrimethylammonium bromide in a 500ml three-necked flask, dissolve it in 200ml of water under the condition of a water bath at 50°C, and dissolve 20ml of ring Hexane was added dropwise to the aqueous solution of cetyltrimethylammonium bromide and stirred for 20 minutes to prepare an emulsion. Weigh 20g of styrene-butadiene vulcanizate powder and add it into a three-necked flask. The stirring speed of the mixer is 100r / min, and the swelling is 40min. 0.6g of glutathione was added into the three-necked flask, the speed of the stirrer was 300r / min, and the reaction was carried out for 18h. Then suction filter, wash and dry to obtain desulfurized rubber powder. The prepared desulfurized rubber powder is masticated on an open mill for 12 minutes, and then the finished product of reclaimed rubber is obtained; the finished reclaimed rubber can be directly molded on a vulcanizing machine at 145°C for 3 minutes to obtain a rubber sample. Table 3 com...

Embodiment 3

[0028] Example 3: (1) The yeast cell and water are completely frozen in a container at a volume ratio of 1:1, and the cell and the container are quickly placed in boiling water at 100°C for 15 minutes of pyrolysis, and then frozen for use. The cell wall of Saccharomyces cerevisiae is cleaved during the process of sudden heating from the frozen state, releasing the thiol-containing compounds in the yeast cells. (2) Take 2.0g of hexadecyltrimethylammonium bromide in a 250ml three-necked flask, dissolve it in 60ml of water under the condition of a water bath at 60°C, and dissolve 60ml of the ring under the condition of stirring speed of 1000r / min Add hexane to the aqueous solution of cetyltrimethylammonium bromide and stir for 20 minutes to prepare an emulsion. Weigh 20g of self-made natural rubber powder and add it into a three-necked flask. The stirring speed of the mixer is 100r / min, and the swelling is 40min. Melt 18ml of the lysed yeast cells obtained in step (1) in a water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com