VOC waste gas microwave combustion furnace

A microwave combustion and exhaust gas technology, applied in the direction of combustion method, combustion type, incinerator, etc., can solve the problems of high safety, destruction, high processing cost, etc., and achieve the effects of reducing pollution and harm, short reaction time, and simple assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

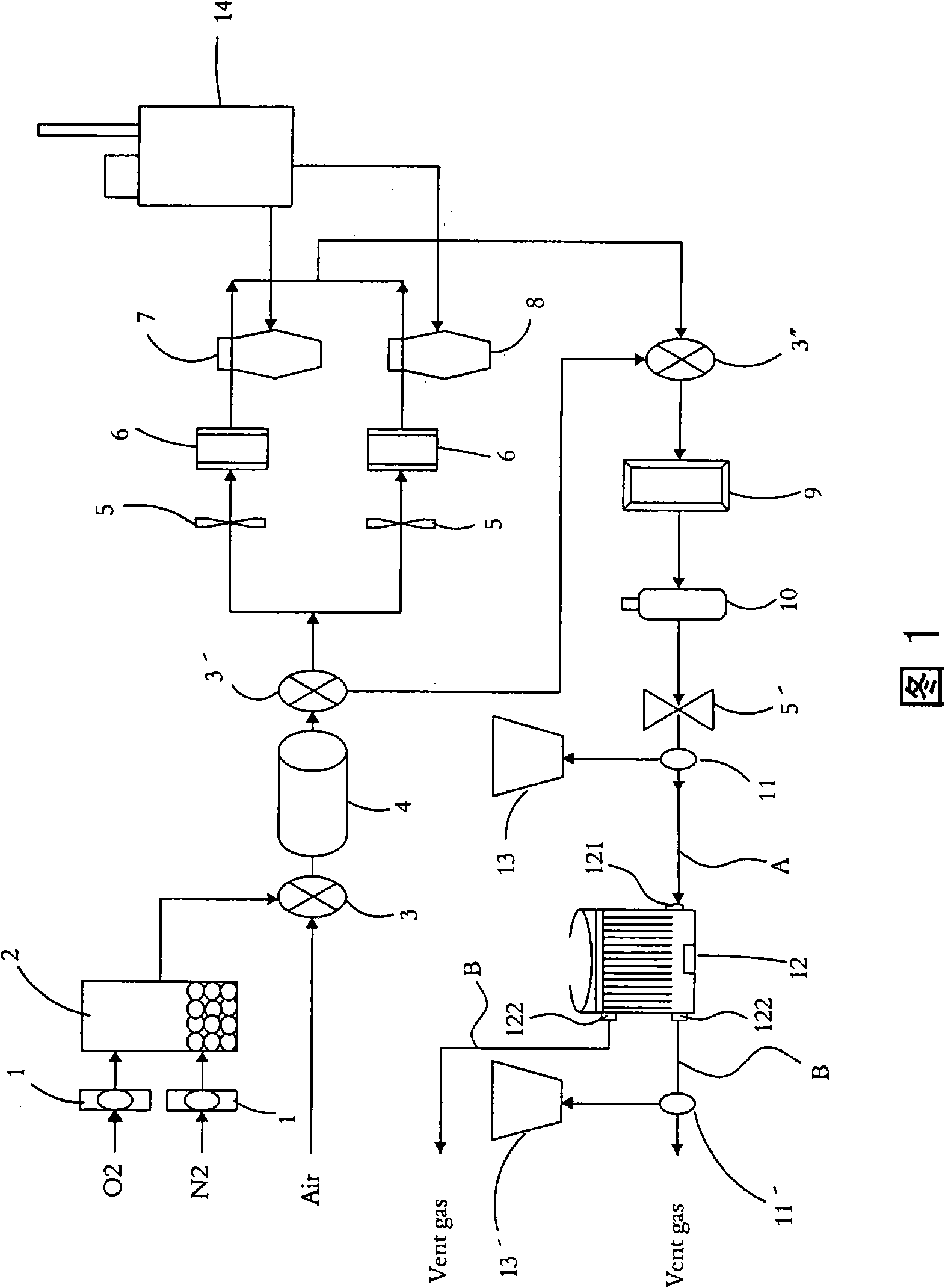

[0018] As shown in Figure 1, it is the schematic diagram that reaction tank of the present invention is connected with other relevant equipment: can understand gas (such as oxygen O by this figure) 2 , Nitrogen N 2 etc.) flow into the gas mixing tank 2 through the flow meter 1, a valve 3 is connected between the gas mixing tank 2 and one end of the filter 4, and the valve 3 can introduce air (Air), and the other end of the filter 4 is connected with a valve 3'. The above-mentioned mixed gas flowing through the filter 4 can flow to the path formed by the valve 5, the flow controller 6 and the organic waste gas 7 after passing through the valve 3', and flow to the path formed by the valve 5, the flow controller 6 and the humidity controller 8. The path formed in series will flow to the valve 3" after passing through these two paths; or, directly introduce the mixed gas passing through the valve 3' into the valve 3"; the aforementioned organic waste gas 7 and humidity controller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com