Method for preparing protein peptide with immobilization proteolytic enzyme protolysate

A technology of immobilized protease and immobilized enzyme, applied in the field of producing protein peptides with immobilized protease, can solve the problems of application limitation and high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Using Pluronic P123 as template, trimethylbenzene (TMB) as pore expander, tetraethyl orthosilicate (TEOS) as organosilicon source, water as solvent, and hydrochloric acid to adjust the pH value of the system to synthesize ordered silicon-based mesoporous Material SBA-15. The molar ratio of each material in the reaction is: 1TEOS: 0.017P123: 0.6TMB: 5.85HCl: 165H 2 O. Under magnetic stirring, add the silicon source into the template agent acidic aqueous solution, stir at room temperature for 2 hours, and then statically crystallize at 35°C for 24 hours; react in an autoclave at 100°C for 24 hours, filter, and wash with deionized water until Neutral, after drying at room temperature, calcined at 550°C for 4 hours to obtain SBA-15 carrier. The carrier has a most probable pore diameter of 9.8nm and a specific surface area of 977m 2 / g.

[0021] Add 5 g of the mesoporous material prepared by the above method to 3 mg / ml alkaline protease, shake at room temperature for 1...

Embodiment 2

[0023] Weigh 0.50g of casein, accurate to 0.01g, moisten it with a small amount of 0.5mol / l sodium hydroxide solution, add about 800ml of buffer solution with an appropriate pH=7.5, stir while heating in a boiling water bath until completely dissolved, After cooling, transfer to a 1000ml volumetric flask, dilute with buffer solution to volume.

Embodiment 3

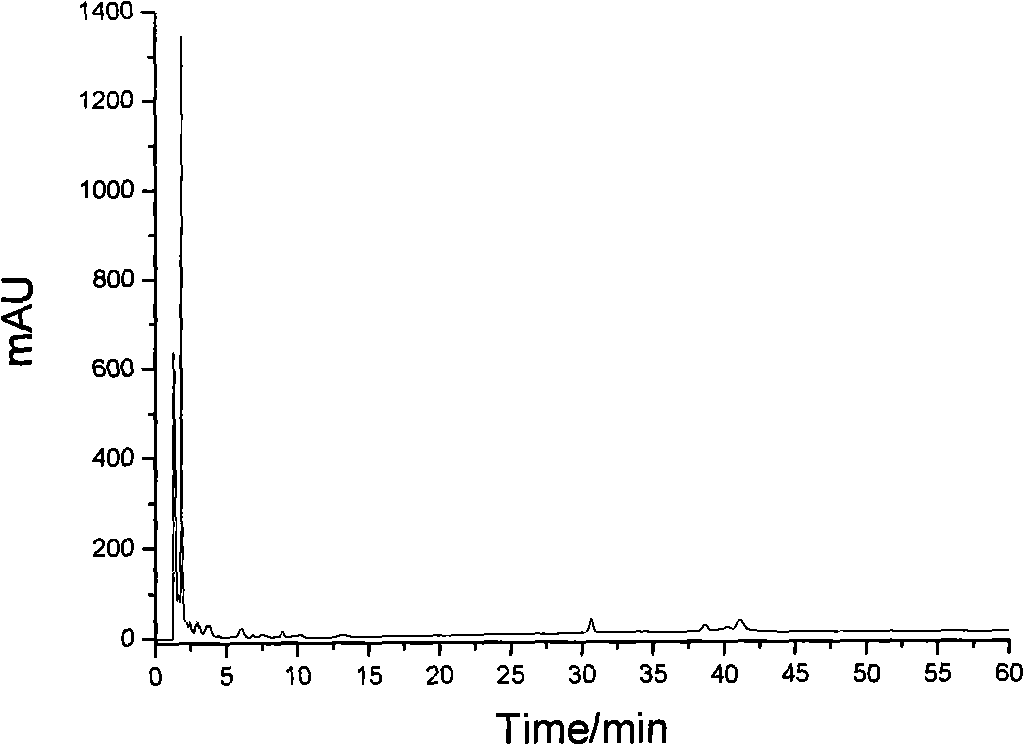

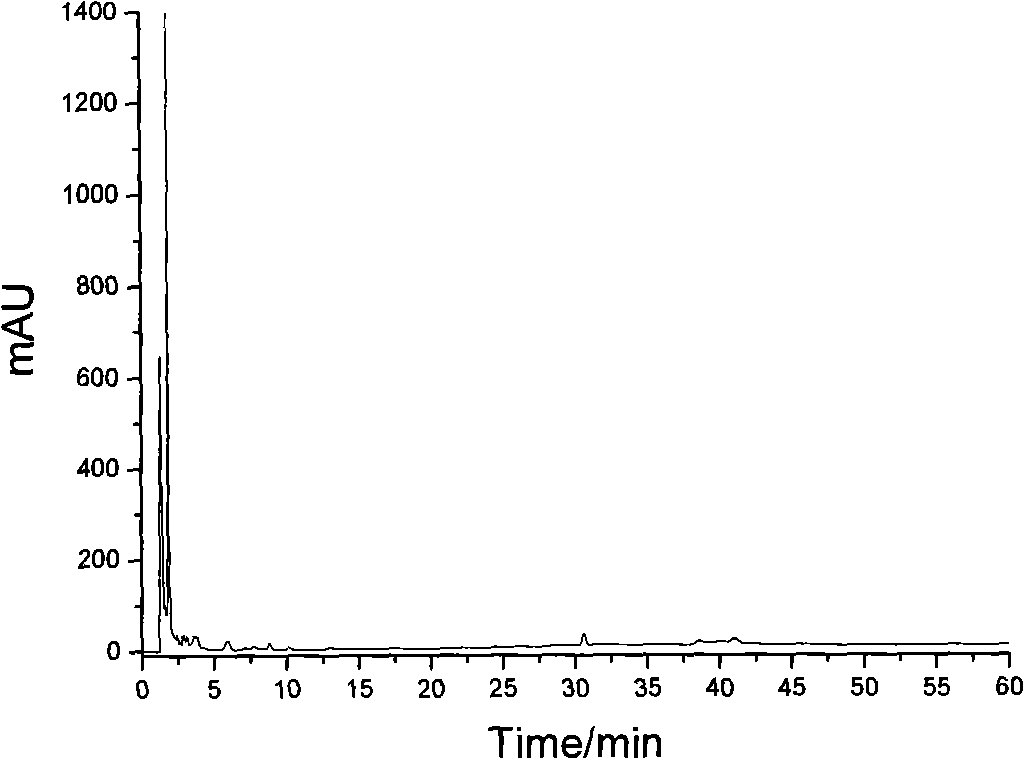

[0025] Dissolve casein at a concentration of 0.5 mg / ml in a phosphate buffer solution with a pH of 8.0, flow through the reactor prepared in Example 1 above at a rate of 1000 ml / h at 50° C., collect the effluent, and concentrate , spray-dried protein peptides. The obtained protein peptide and the protein peptide hydrolyzed by free alkaline protease were subjected to HPLC analysis, and the results are shown in the accompanying drawings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com