Edible membrane material and preparation thereof

A technology of edible film and film material, which is used in food preparation, application, food preservation and other directions to achieve the effect of reducing production cost, good compatibility, good antiseptic and bacteriostatic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

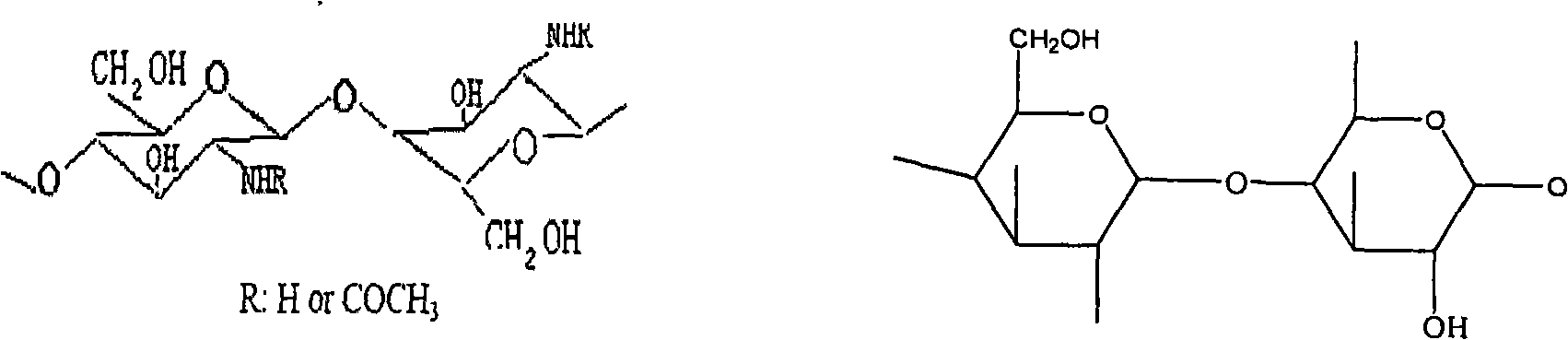

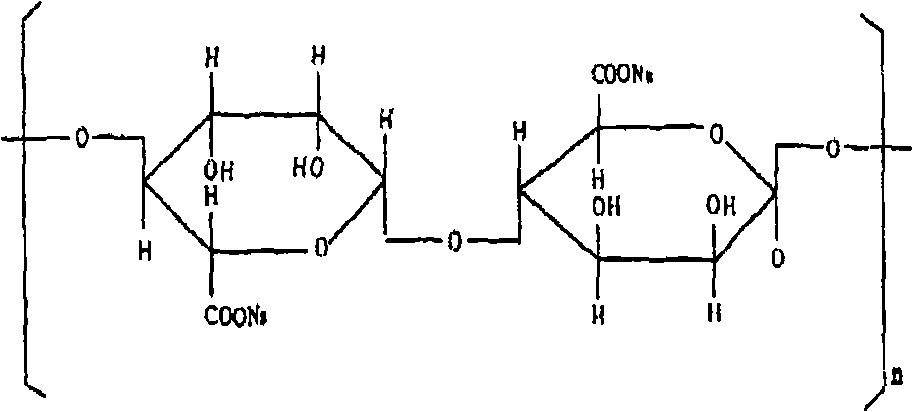

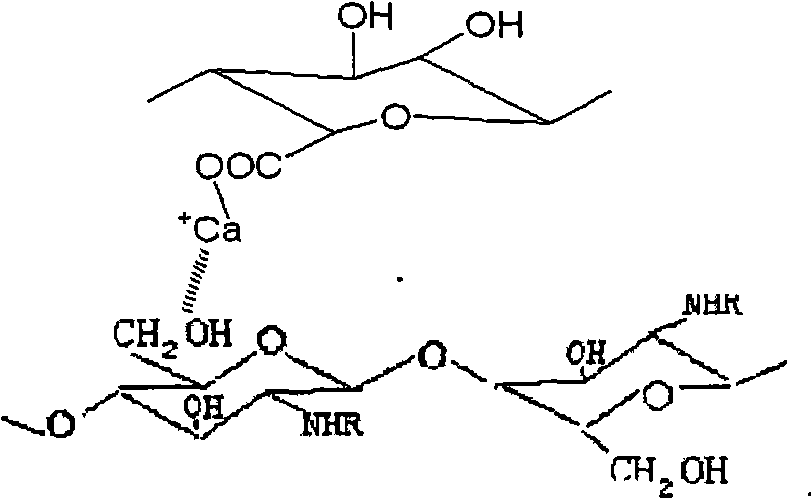

Method used

Image

Examples

Embodiment 1

[0051] Disperse 20 parts by weight of amylopectin and 4 parts by weight of starch acetate in distilled water at 95°C, so that the mass concentration of starch and its derivatives in the dispersion system is 5%;

[0052] Disperse 50 parts by weight of commercially available chitosan powder (200 meshes in particle size) (about 85% degree of deacetylation) in an appropriate amount of water, maintain rapid stirring, and add lactic acid to make chitosan completely dissolve into lactic acid of chitosan Solution, control the concentration of lactic acid in this solution to reach about 0.01M (pH value between 3~3.5), and the mass concentration of chitosan is about 10%;

[0053] Dissolve 5 parts by weight of sodium alginate in 100 parts by weight of water to make a solution, mix the solution with the above-mentioned aqueous dispersion of starch and its derivatives, and the lactic acid solution of chitosan, and maintain the temperature of the mixed system (lactic acid system) Slowly add...

Embodiment 2

[0058] Dispersing 15 parts by weight of starch and 4 parts by weight of acetate starch in distilled water at 90°C, so that the mass concentration of starch and its derivatives in the dispersion system is 5%;

[0059] The commercially available chitosan of 50 weight parts is dissolved in the lactic acid solution of 0.01M, makes the mass concentration of the chitosan in this solution be 5%;

[0060] Dissolve 5 parts by weight of sodium alginate in 100 parts by weight of water to make a solution, mix the solution with the above-mentioned aqueous dispersion of starch and its derivatives, and the lactic acid solution of chitosan, and maintain the temperature of the mixed system (lactic acid system) Slowly add CaCO at about 60°C under high-speed stirring at 2500 rpm 3 powder until a colloidal solution with a pH value of about 6.5 is obtained;

[0061] Concentrate the resulting colloidal solution at about 65°C until the total sugar concentration in the solution exceeds 5%, keep the ...

Embodiment 3

[0065] Disperse 20 parts by weight of starch and 4 parts by weight of acetate starch in distilled water at 90°C, so that the mass concentration of starch and its derivatives in the dispersion system is 3%; then add 35 parts by weight of Chitosan, 5 parts by weight of chitosan sulfate, 10 parts by weight of sodium alginate, stirring and dispersing, and adding lactic acid to it to dissolve the chitosan material therein to form a lactic acid system with a pH of 3 to 3.5 ;

[0066] Maintain the temperature of the lactic acid system at about 70°C, and add calcium carbonate powder under high-speed stirring at 2300 rpm until obtaining a colloidal solution with a pH of 6.8 (it can be observed that most of the added calcium carbonate is in the colloidal solution) dissolved and participated in the reaction, only a very small amount of calcium carbonate is uniformly dispersed in the colloidal solution);

[0067] Concentrate the obtained colloidal solution at about 60°C to a total sugar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com