Preparation of zircite porous ceramic

A technology of porous ceramics and zirconia, which is applied in the field of preparation of porous ceramics, can solve problems such as poor uniformity, irregular distribution of material pores, and difficult control of the preparation process, and achieve the effects of regular distribution, adjustable size, and small thermal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

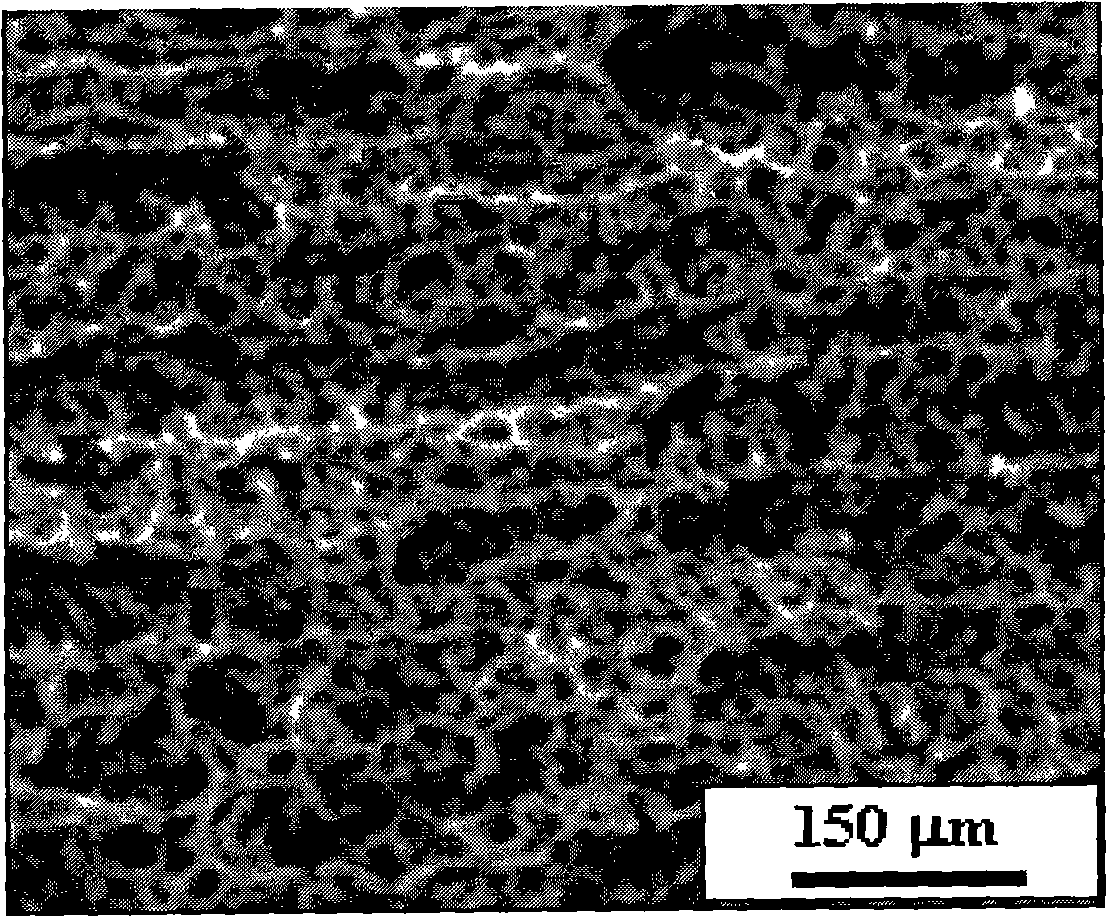

Image

Examples

specific Embodiment approach 1

[0008] Embodiment 1: The preparation method of zirconia porous ceramics in this embodiment is realized by the following steps: 1. Partially stabilized ZrO by volume percentage of 10-35% 2 Powder with 65-90% C 10 h 16 Mix, then add polystyrene, put it into a ball mill jar, put it in a water bath at 60-70°C for 18-22 hours, and get a slurry; 2. Put the mold in liquid nitrogen for pre-cooling, and then pour Put in the slurry, and after the slurry is solidified, place it in the environment of -33~-37℃ and freeze it for 22~26 hours; 3. After the frozen slurry is released from the mold, place it in the room temperature air environment to dry for 46~50 hours, and then put it in the sintering In the furnace, heat up to 1450-1650°C at a heating rate of 2-4°C / min, heat-preserve and sinter for 2-4 hours, and then cool to room temperature at a cooling rate of 5-10°C / min to obtain porous zirconia ceramics; the steps The addition of polystyrene in the first step is 2~3% of the total weigh...

specific Embodiment approach 2

[0009] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, 20% of the partially stabilized ZrO 2 Powder with 80% C 10 h 16 After mixing, polystyrene was added, and then put into a ball mill jar, and placed in a water bath at 65°C for ball milling and wet mixing for 20 hours. Other steps and parameters are the same as those in Embodiment 1.

[0010] In this embodiment C 10 h 16 The mass purity of the product is >97%; ball milling wet mixing is carried out by using zirconia balls with a diameter of 5mm and mixing at a speed of 150-250r / min.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one is the partially stable ZrO in step one 2 The powder contains Y with a molar percentage of 5mol%. 2 o 3 . Other steps and parameters are the same as those in Embodiment 1.

[0012] This embodiment ZrO 2 Y in powder 2 o 3 as a stabilizer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com