Formed nano-carbon fibre carrier and preparation thereof

A nano-carbon fiber and carrier technology, applied in the field of materials, can solve the problems that compression molding method is not suitable for mass production, limited application, complicated process, etc., and achieve the effect of simple and convenient molding equipment, easy scale production and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

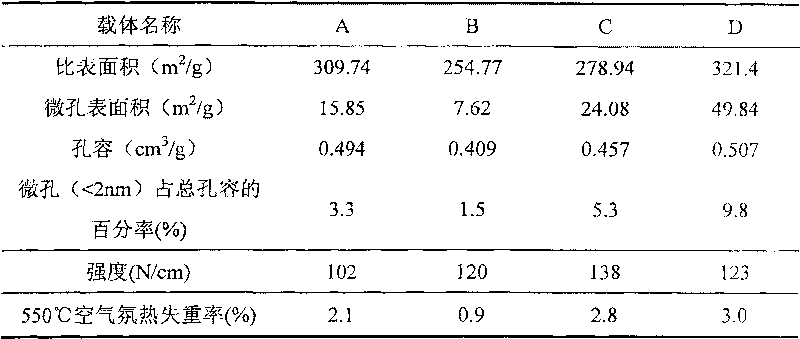

[0023] Example 1 , Preparation of carbon nanofiber carrier

[0024] Weigh 40g of nano-carbon fiber powder, 22.2g of pseudo-boehmite dry glue (produced by Fushun Petrochemical Research Institute, with an alumina content of 60%), 1g of citric acid, 1g of turmeric powder, 1g of nitric acid, and 79g of water. The above samples were fully mixed and kneaded into a plastic material and added to an extruder (F-26 twin-screw extruder, manufactured by South China University of Science and Technology Industrial Factory) to extrude into a clover-shaped strip with a diameter of 1.4mm. After air drying overnight, it was dried at 110°C for 4 hours. The dried sample was placed in a muffle furnace, the temperature was raised to 400° C. at a rate of 3° C. / min, and kept at this temperature for 6 hours to prepare carrier A.

Embodiment 2

[0025] Example 2 , Preparation of carbon nanofiber carrier

[0026] Take by weighing 40g of nano-carbon fiber powder, 114.2g of pseudo-boehmite dry rubber powder (pural SB powder produced by Sasol company, with an alumina content of 70%), 1g of citric acid, 1g of turmeric powder, add 1.5g of nitric acid, 18.5g of water, The above samples were fully mixed and kneaded into a plastic material and added to an extruder (F-26 twin-screw extruder, manufactured by the South China University of Science and Technology Industrial Factory), extruded into a four-leaf clover shape, and the dried sample was placed in an inert Atmosphere (Ar, N 2 ) to 600° C. for 4 hours to obtain carrier B.

Embodiment 3

[0027] Example 3 , Preparation of carbon nanofiber carrier

[0028] Take by weighing 40g of nano-carbon fiber powder, 66.7g of pseudo-boehmite dry rubber powder (pural SB powder produced by Sasol Company, with an alumina content of 70%), 0.2g of citric acid, 0.2g of kale powder, add 1.5g of nitric acid, 38.5g of water g. Mix the above samples thoroughly. Carrier C was prepared according to the conditions described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com