Method for separating and extracting alfapsin

A technology of chymotrypsin and chymotrypsinogen, which is applied in the field of biopharmaceuticals, can solve the problems of reducing investment and production costs, less reusable times, and expensive affinity chromatography media, so as to reduce investment and production costs and benefit the environment Effects of protection and reduction of process load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

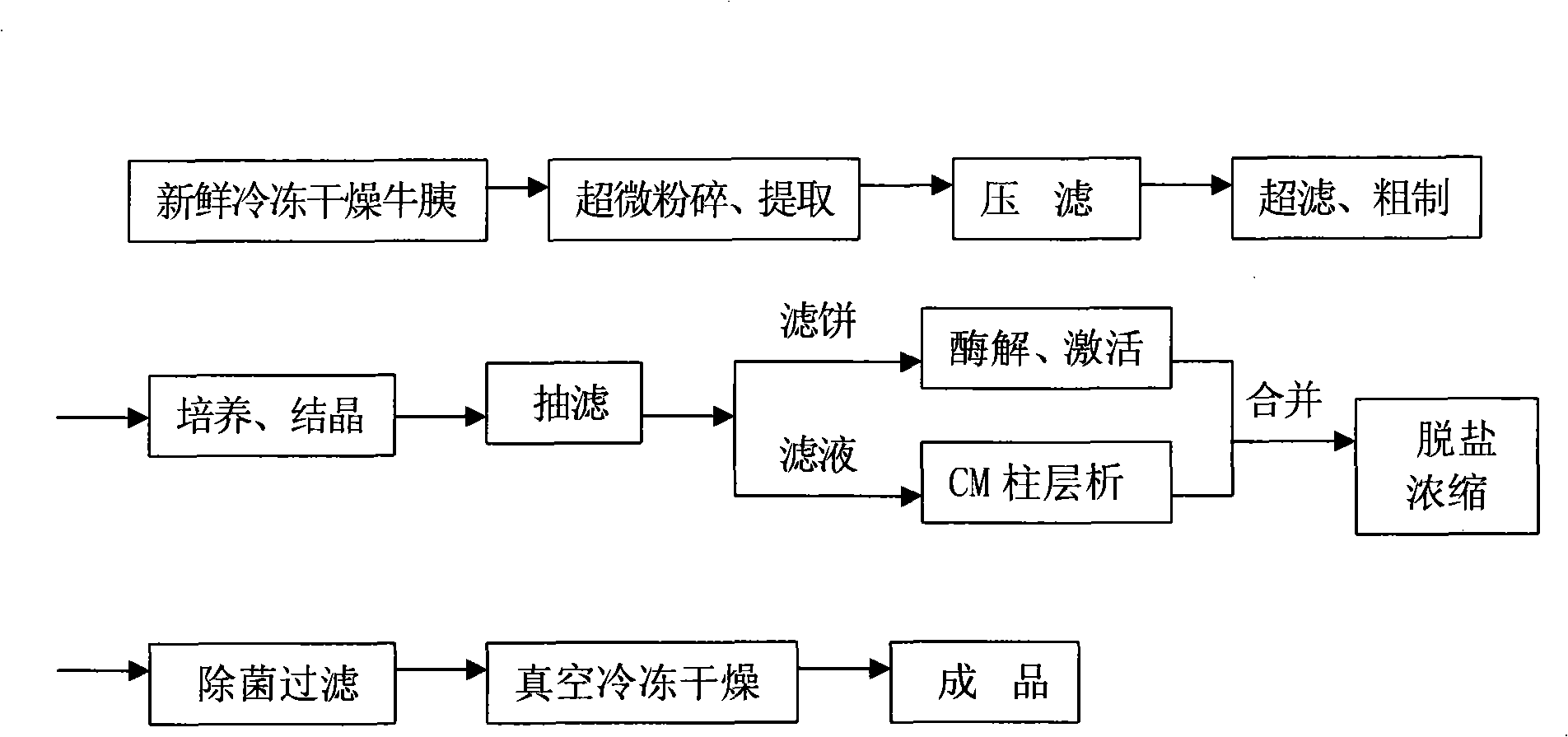

Image

Examples

Embodiment 1

[0023] ① Prepare 4000L 0.125mol / L sulfuric acid solution in a 6000L reaction tank. Cut 1000kg of fresh bovine pancreas from -18°C to -20°C cold storage into slices with a slicer, then crush it into a slurry with a high-pressure homogenizer, add it to the above-mentioned reaction tank, and add a 5-15°C refrigerant to the jacket of the reaction tank Liquid protection, stirring and extracting for 24 hours, after the extraction is completed, add filter aid and stir well, pump the extract into 40m 2 Plate and frame filter press for liquid-solid separation. After separation, the solid residue is bagged and disposed of according to environmental protection requirements. The resulting supernatant should be clear without turbidity and pumped into the ultrafiltration tank. Use a 40KD ultrafilter to perform ultrafiltration separation on the liquid in the ultrafiltration tank. After the ultrafiltration is over, use a 10KD ultrafilter to perform ultrafiltration on the above ultrafiltrat...

Embodiment 2

[0031] ① Prepare 2500L 0.125mol / L sulfuric acid solution in a 5000L reaction tank. Cut 500 kg of fresh bovine pancreas stored in a cold storage at -18°C to -20°C into slices with a microtome, and then pulverize into a slurry with a high-pressure homogenizer. Put it into the above reaction tank, add 5 ~ 15 ℃ refrigerant liquid protection in the jacket of the reaction tank, stir and extract for 18 hours, after the extraction is completed, add filter aid and stir well, pump the extract into 30m 2 Plate and frame filter press for liquid-solid separation. After separation, the solid residue is bagged and disposed of according to environmental protection requirements. The resulting supernatant should be clear without turbidity and pumped into the ultrafiltration tank. Use a 40KD ultrafilter to perform ultrafiltration separation on the liquid in the ultrafiltration tank. After the ultrafiltration is over, use a 10KD ultrafilter to perform ultrafiltration on the above ultrafiltrate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com