Acid brilliant pink-calcium oxalate adsorbing material and its preparation method

An acid peach, adsorption material technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problem of long decolorization cycle, and achieve the effect of short settling time, good adsorption performance and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

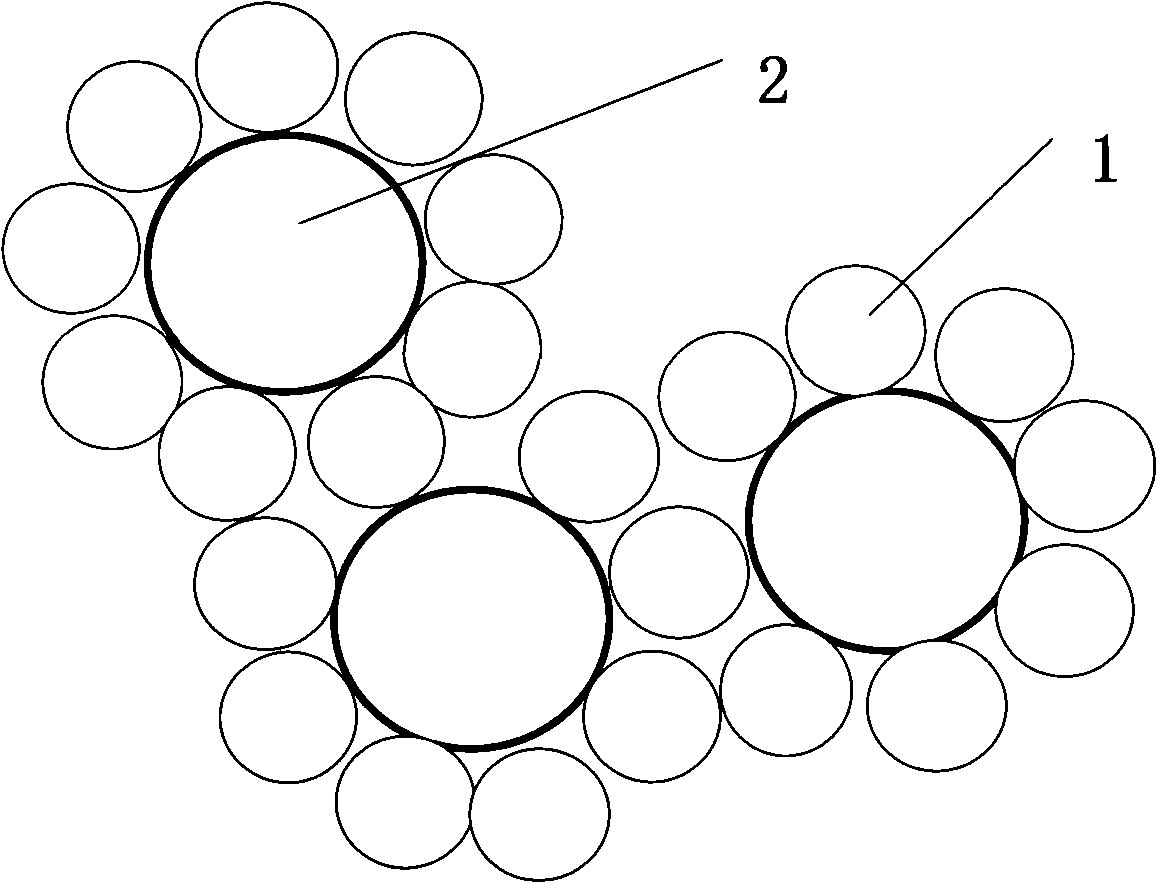

Image

Examples

Embodiment 1

[0027] Calcium chloride, a soluble calcium-based framework material, is selected. Calcium chloride is added with water to form a calcium chloride solution with a concentration of 5% (w / w, weight percentage). The sodium oxalate is added with water to form a sodium oxalate solution with a concentration of 2% by weight. In a 2000ml beaker, under magnetic stirring conditions, add 800ml commercially available concentration of 95% technical grade ethanol, 400ml 10mM acid red 138 and 800ml 5% (w / w) calcium chloride solution, and then add 2% (w / w ) Sodium oxalate solution 200ml, mixing reaction 10~30 minutes, sedimentation 1h, 3 times of water washing (3 * 2000ml) sedimentation, leave overnight, collect sedimentation, be the suspension liquid product of the present invention.

[0028] The above-mentioned suspension product can also be made into a solid adsorption material product through centrifugation, drying, and crushing.

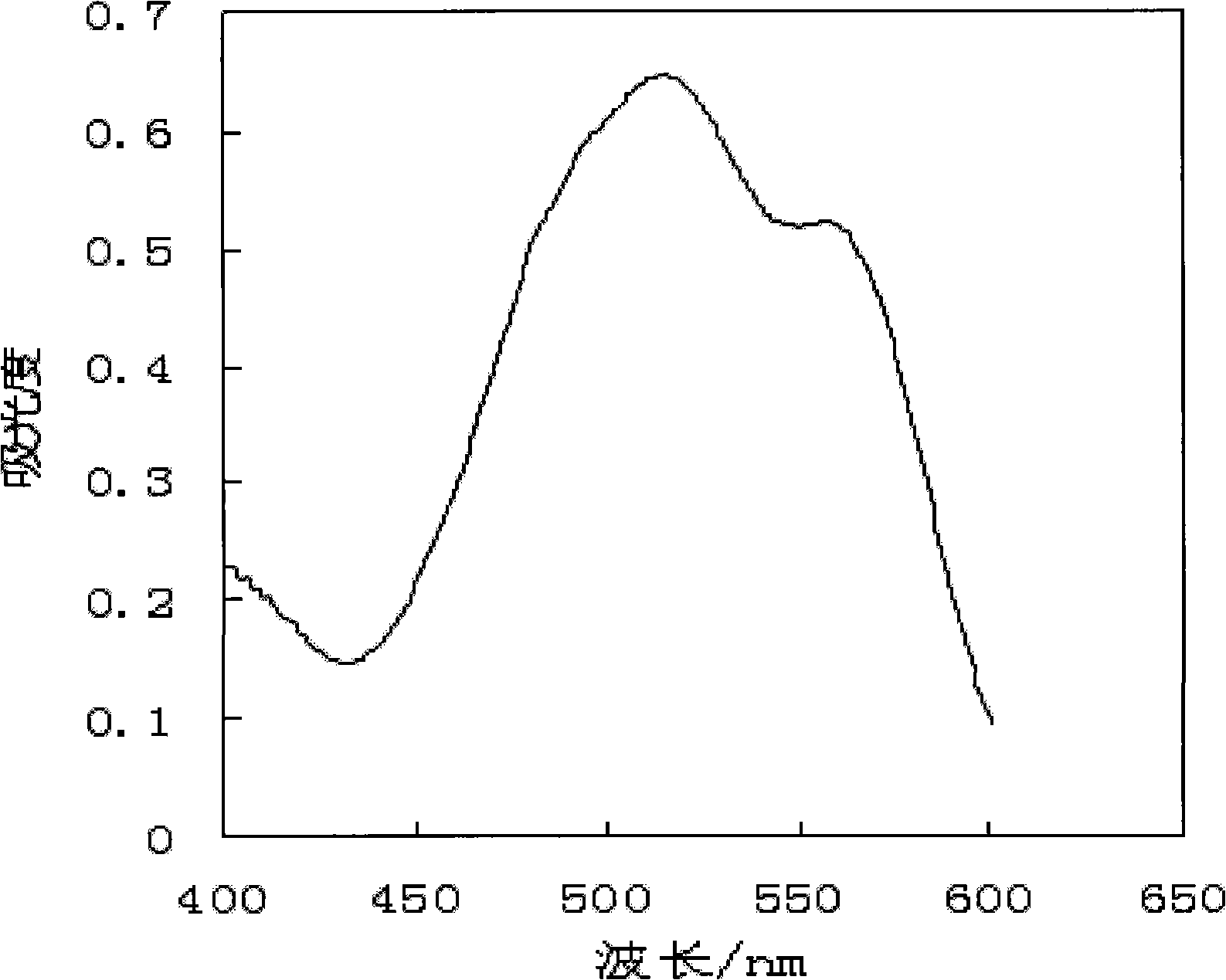

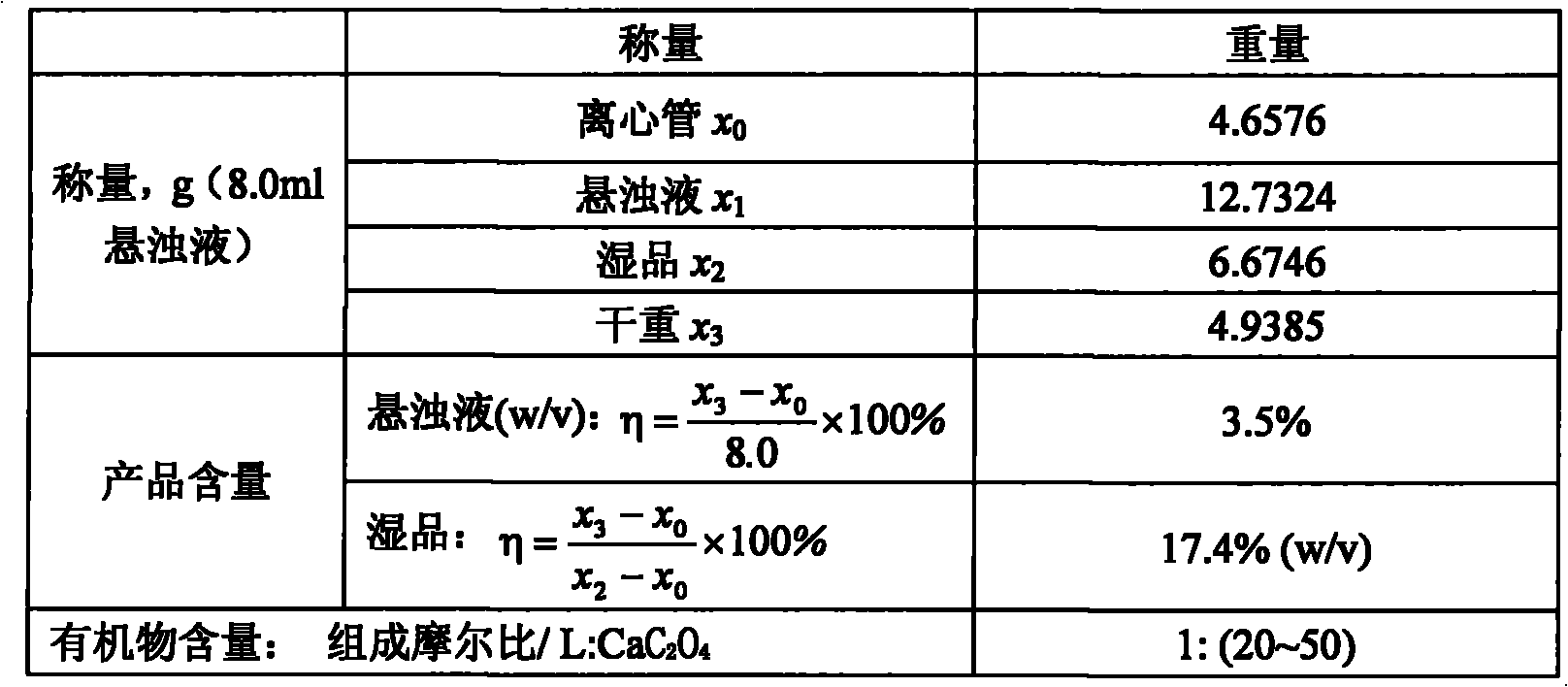

[0029] The composition of the above-mentioned adsorbent ...

Embodiment 2

[0034] The calcium-based skeleton material is calcium oxide of insoluble calcium. Dissolve calcium oxide with 1-10% (w / w) hydrochloric acid first, then neutralize it with 1%-10% (w / w) sodium hydroxide solution to pH 5-7, and finally add water to prepare a concentration of 20% by weight. % calcium solution. 1%-10% (w / w) sodium hydroxide is used to dissolve oxalic acid, and water is added to prepare a 5% sodium oxalate solution by weight. Acid red 138 dye wastewater was made into inclusion solution with a concentration of 20 mM. Commercially available methanol with a concentration of 75% was used as a colloidal solvent. According to calcium solution: sodium oxalate solution: inclusion solution: colloidal solvent = 4 parts: 1 part: 2 parts: 4 parts by weight. Then add acid red 138 inclusion solution and colloidal solvent into the calcium solution, add sodium oxalate solution under stirring condition, mix and react for 10 to 30 minutes, the precipitate is made into a suspension...

Embodiment 3

[0036] When the above-mentioned acid pink-calcium oxalate adsorption material produced by the method of the present invention was used to process cationic dye wastewater, 3 kinds of basic dye wastewater samples were prepared in a 10ml colorimetric tube: basic pink (chroma 480), acid brilliant blue 6B ( Chroma 320), ethyl violet (chroma 390). Add 0.1%, 0.3%, and 0.5% acid pink-calcium oxalate adsorption material of the sample weight respectively, and the measured data are shown in Table 2 after 30 minutes of precipitation. It can be seen that for acid brilliant blue 6B and ethyl violet, only 0.1% of the material can absorb more than 95% of the color, and the sedimentation is fast. For basic pink, adding 0.5% material can absorb more than 90% of the color. Therefore, the material has obvious adsorption effect on cationic dyes.

[0037] Table 2 Adsorption experimental data of three dyes

[0038]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com