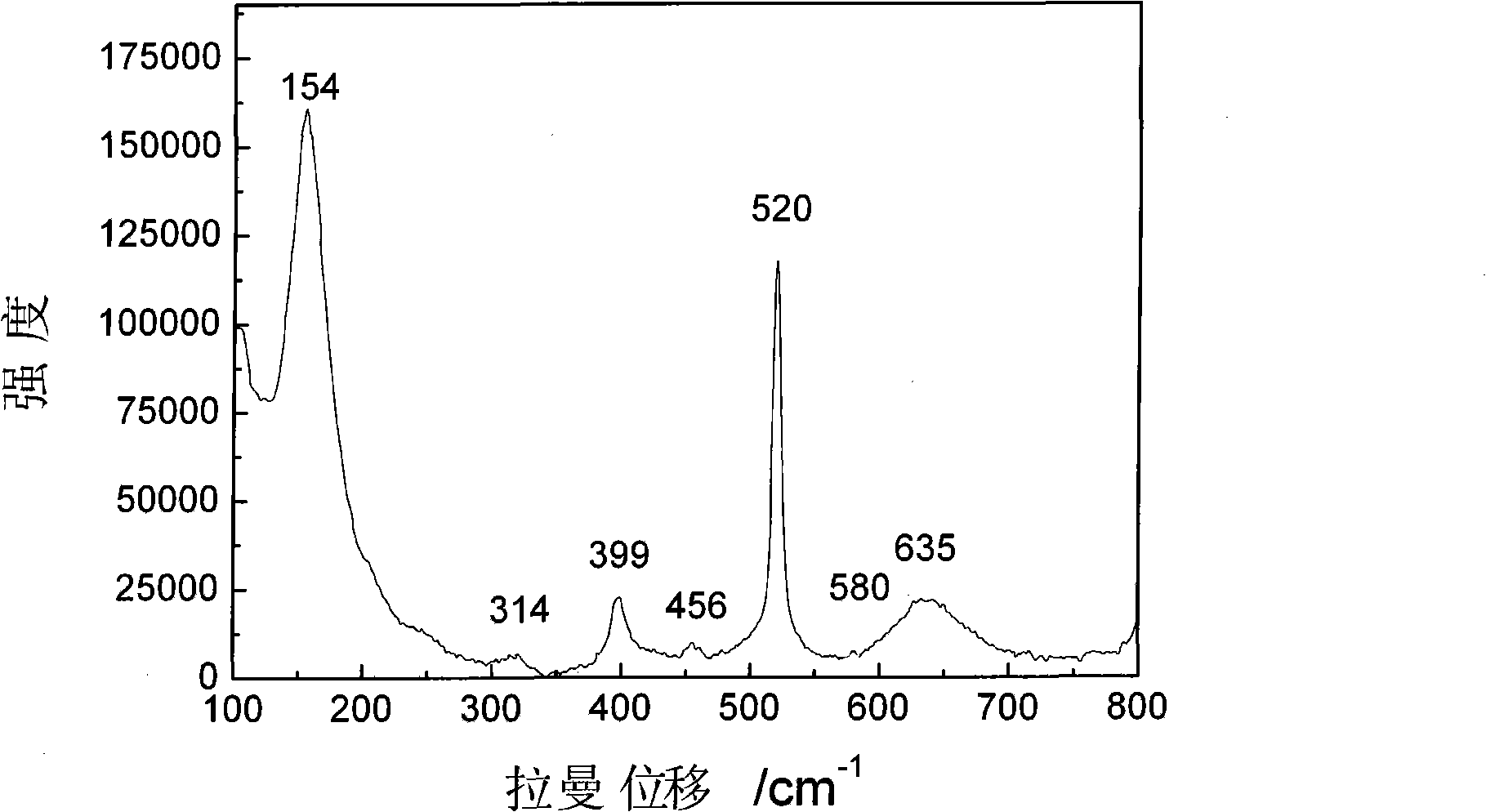

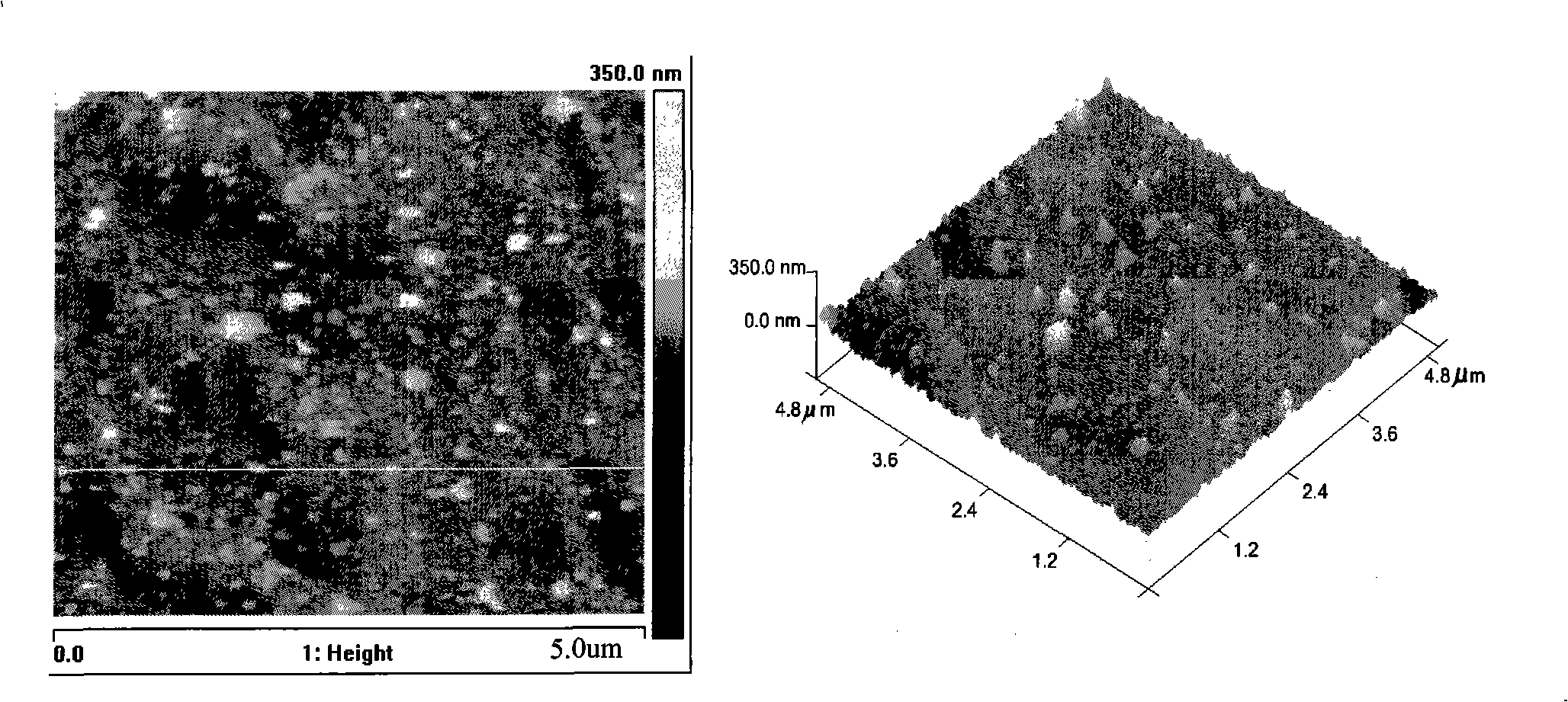

Method for preparing immobilized DNA guiding substrate surface nano-titanium dioxide film growth

A nano-titanium dioxide and thin-film growth technology, applied in the direction of coating, etc., can solve the problems of complex equipment, high substrate temperature, and weak substrate bonding, etc., and achieve the effect of uniform film surface and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The preparation method for the growth of nano-titanium dioxide film on the surface of the substrate guided by immobilized DNA comprises the following steps:

[0025] (1) Substrate cleaning and drying:

[0026] Wash the single crystal silicon wafer with chloroform and distilled water successively under ultrasonic enhancement to wash away the floating dust and organic impurities on the surface, take out the substrate from the washing solution and place it in a mixed solution of concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 7:3 Soak at 80°C for 20 minutes, take it out, wash the substrate with distilled water and isopropanol in turn, and dry it with nitrogen;

[0027] (2) Immobilization of DNA molecules on the surface of the substrate:

[0028] ①Put the cleaned and dried substrate into a solution of 0.5% by volume of aminopropyltrimethoxysilane in anhydrous cyclohexane, and soak it at 25°C for 90 minutes to form self-assembly of aminosilane on the...

Embodiment 2

[0037] The preparation method for the growth of nano-titanium dioxide film on the surface of the substrate guided by immobilized DNA comprises the following steps:

[0038] (1) Substrate cleaning and drying:

[0039] Wash the monocrystalline silicon wafer with chloroform and water under ultrasonic enhancement, take out the substrate from the washing liquid, and soak it in the mixed solution of concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 7:3 at 90°C for 20 minutes, take it out and put The substrate was cleaned with distilled water and isopropanol, and dried with nitrogen;

[0040] (2) Immobilization of DNA molecules on the surface of the substrate:

[0041] ① Put the cleaned and dried substrate into an anhydrous cyclohexane solution with a volume percentage of 3% aminopropyltriethoxysilane and soak it at 15°C for 30 minutes to form a self-assembled film of aminosilane on the surface layer, take out the treated substrate, wash it with cyclohexane an...

Embodiment 3

[0047] The preparation method for the growth of nano-titanium dioxide film on the surface of the substrate guided by immobilized DNA comprises the following steps:

[0048] (1) Substrate cleaning and drying:

[0049] Wash the glass sheet with chloroform and water under ultrasonic strengthening, take out the substrate from the washing solution, place it in a mixed solution of concentrated sulfuric acid and hydrogen peroxide with a volume ratio of 3:1, soak it for 15 minutes at 85°C, and remove the substrate after taking it out. The slices were washed with distilled water and isopropanol, and dried with nitrogen;

[0050] (2) Immobilization of DNA molecules on the surface of the substrate:

[0051] ① Put the cleaned and dried substrate into an anhydrous toluene solution with a volume percentage of 1.5% aminopropyltriethoxysilane and soak it at 30°C for 60 minutes to form a self-assembled film of aminosilane on the surface, The treated substrate was taken out, washed with cyclo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com