Poly-p-benzene dicarboxylic acid 1,2-propylene glycol ester and copolyester, and preparation thereof

A polyterephthalic acid and propylene glycol technology, which is applied in the field of polyterephthalic acid, can solve the problems of low reactivity and difficult to polymerize, and achieves the effects of excellent performance and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1. direct esterification method

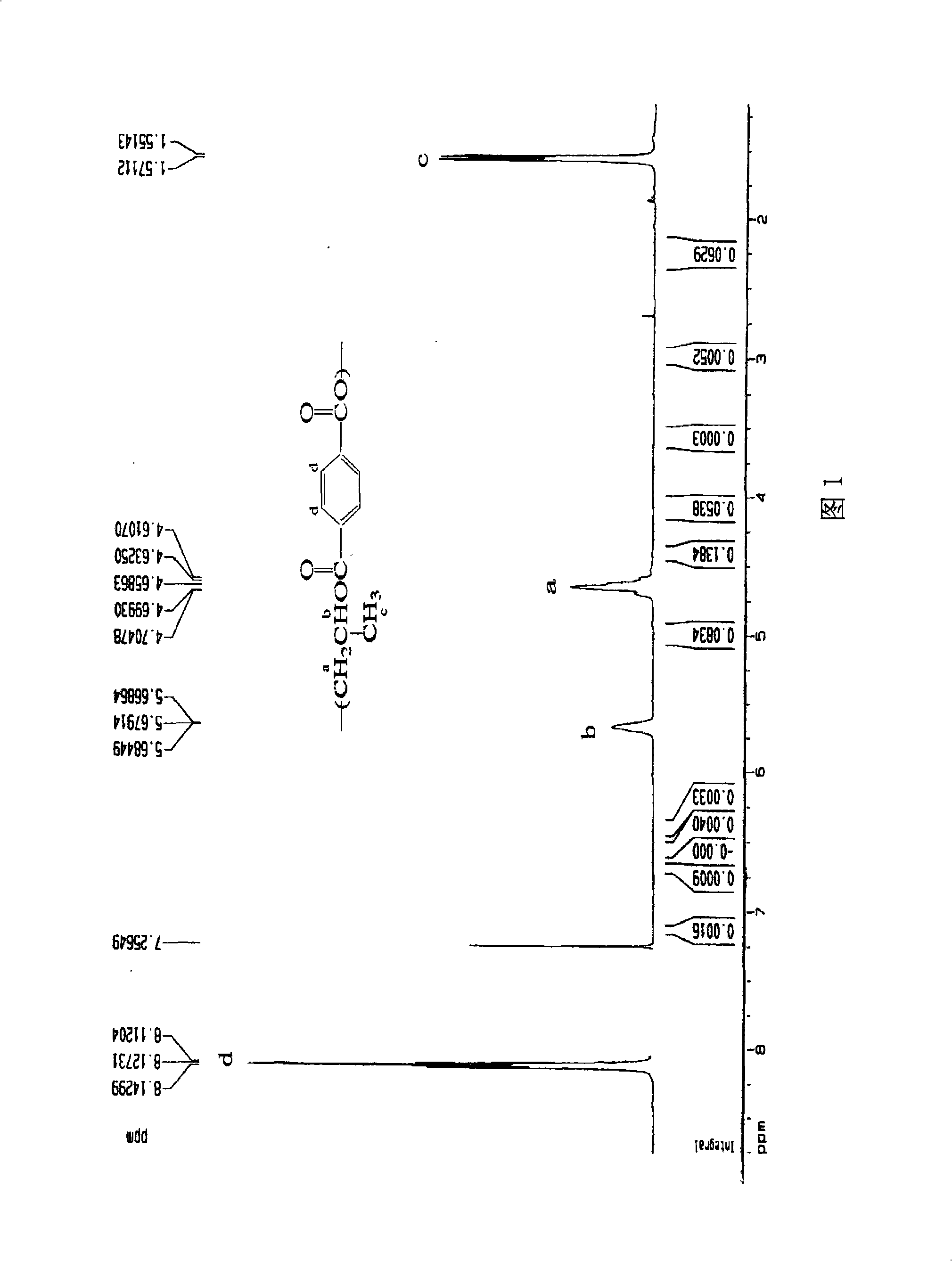

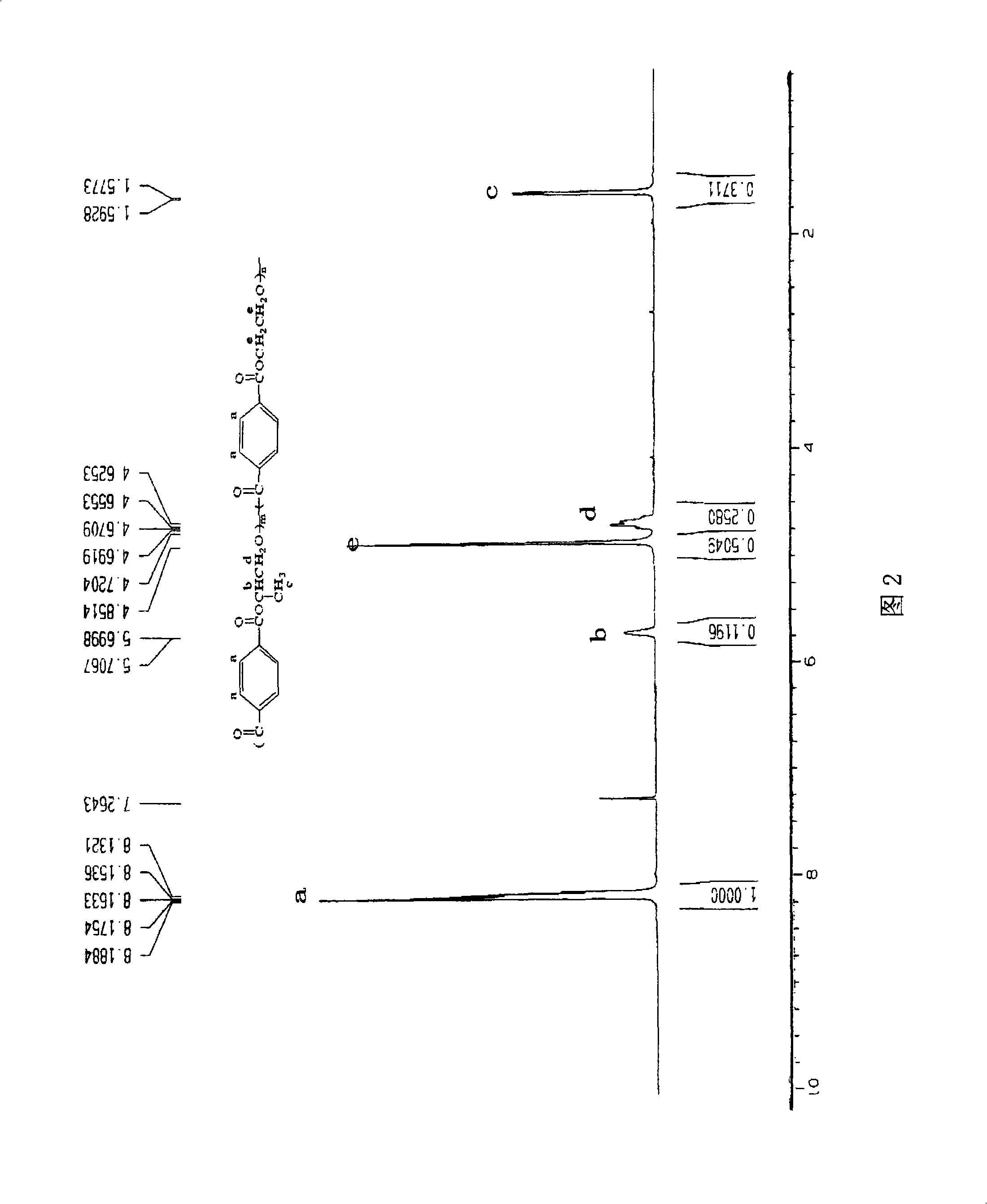

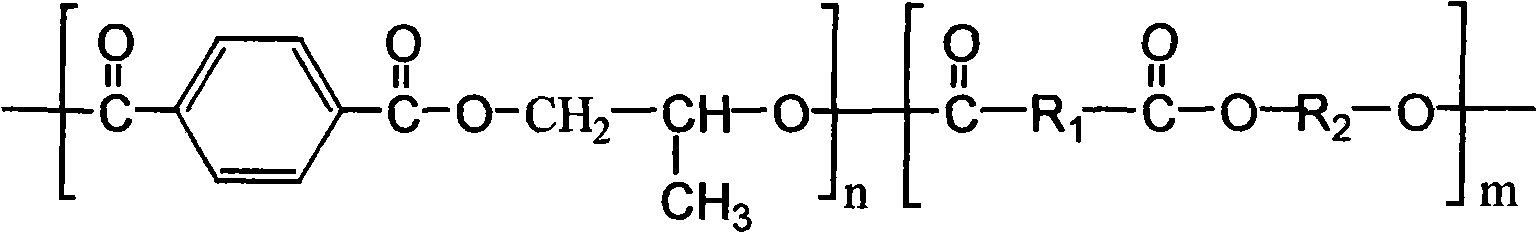

[0055]166g of terephthalic acid, 106.4g of 1,2-propanediol and 0.2g of tetrabutyl titanate were added into a reaction vessel protected by nitrogen gas, the temperature was raised to 250-260°C, and the esterification reaction was carried out under normal pressure. After the esterification reaction, add 0.08g of antimony trioxide and 0.2g of trimethyl phosphate, and polycondense for 4 hours at 270°C and a pressure of 50-80Pa to obtain poly(trimethylene terephthalate). The weight average molecular weight of the sample measured by GPC was 45100, and the molecular weight distribution index was 2.23. Figure 1 shows the sample 1 In the H-NMR spectrum, the NMR peaks of the hydroxyl hydrogen of 1,2-propanediol and the carboxyl hydrogen of terephthalic acid do not appear in this figure, which proves that the samples tested are their polymers.

Embodiment 2

[0056] Embodiment 2. direct esterification method

[0057] Add 162.7g of terephthalic acid, 3.3g of isophthalic acid, 114g of 1,2-propanediol, 0.06g of zinc acetate and 0.1g of butyl titanate into a reaction vessel protected by nitrogen, and raise the temperature to 250-260°C , pressurize 0.1 ~ 0.3MPa, carry out esterification reaction. After the esterification reaction, 0.1 g of butylstannoic acid was added, and polycondensation was carried out at 265°C and a pressure of 30-50 Pa for 3 hours to obtain poly(propylene glycol terephthalate) copolyester. The weight average molecular weight of the sample measured by GPC was 39600, and the molecular weight distribution index was 2.31.

Embodiment 3

[0058] Embodiment 3. direct esterification method

[0059] Add 166.0g of terephthalic acid, 76g of 1,2-propanediol, and 55.0g of cyclohexanedimethanol into a reaction vessel protected by helium, raise the temperature to 250-260°C, pressurize at 0.1-0.3MPa, and carry out the esterification process. reaction. After the esterification reaction, add 0.15g of antimony acetate and 0.1g of tetrabutyl titanate, and polycondense for 3.5 hours at 260°C and a pressure of 80-100Pa to obtain poly(1,2-propylene glycol terephthalate) copolyester , the intrinsic viscosity is . The weight average molecular weight of the sample measured by GPC was 43200, and the molecular weight distribution index was 2.15.

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com