Sapphire and germanate glass infrared composite material and preparation method thereof

A technology of germanate glass and composite materials, applied in chemical instruments and methods, glass/slag layered products, instruments, etc., can solve the problem that infrared material crystals or glass are difficult to meet these requirements at the same time, poor heat resistance and mechanical shock , low hardness and other problems, to achieve the effect of reduced processing and polishing costs, low manufacturing and processing costs, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of sapphire and germanate glass infrared composite material of the present invention comprises the following steps:

[0036] ① Selection of germanate glass

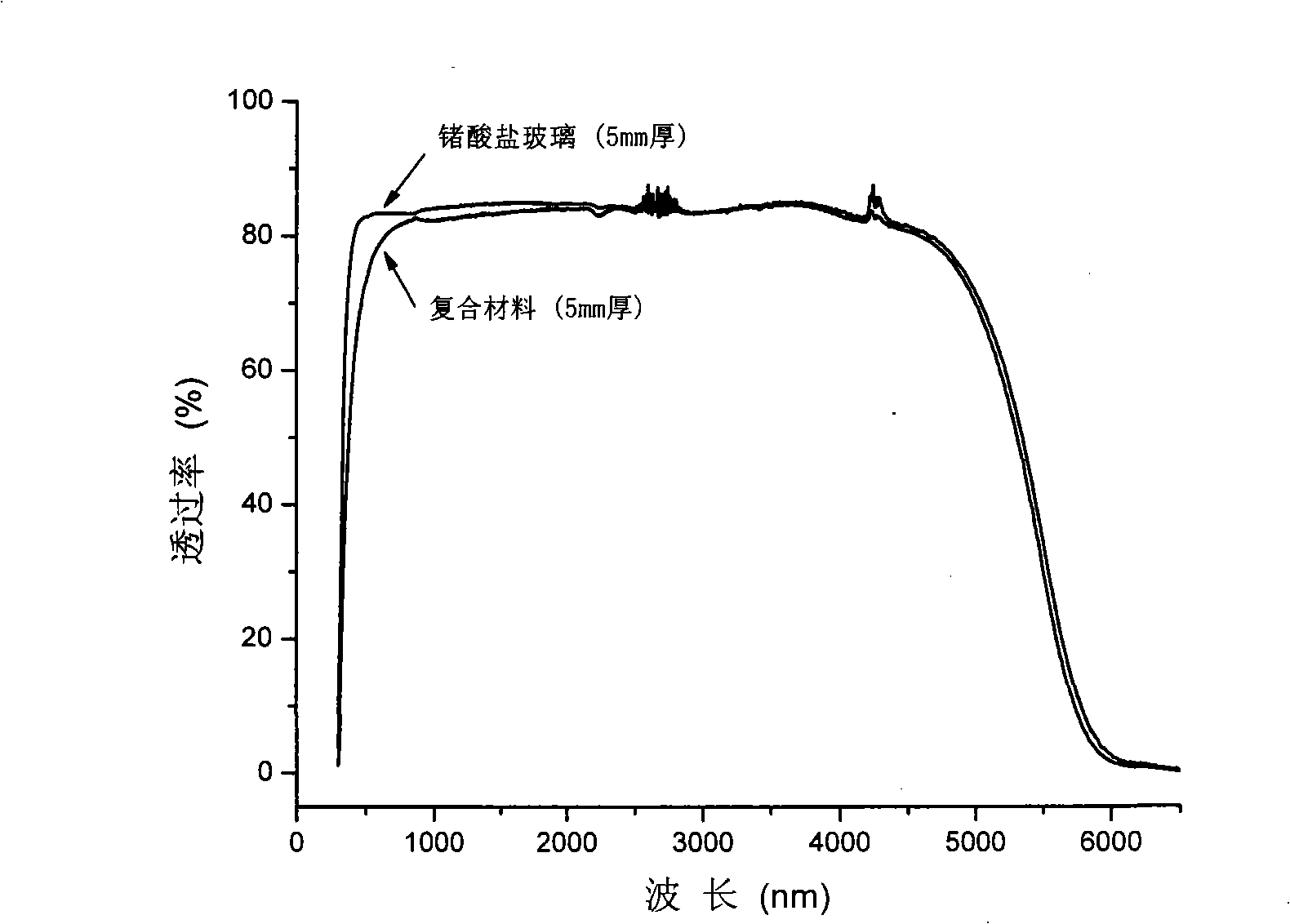

[0037] The selected germanate glass has an average transmittance of not less than 70% in the 0.4-5μm band, and the refractive index of the selected germanate glass matches that of sapphire, with a deviation range of ±0.05; the selected germanium The thermal expansion coefficient of salt glass matches that of sapphire within ±1×10 -6 / K;

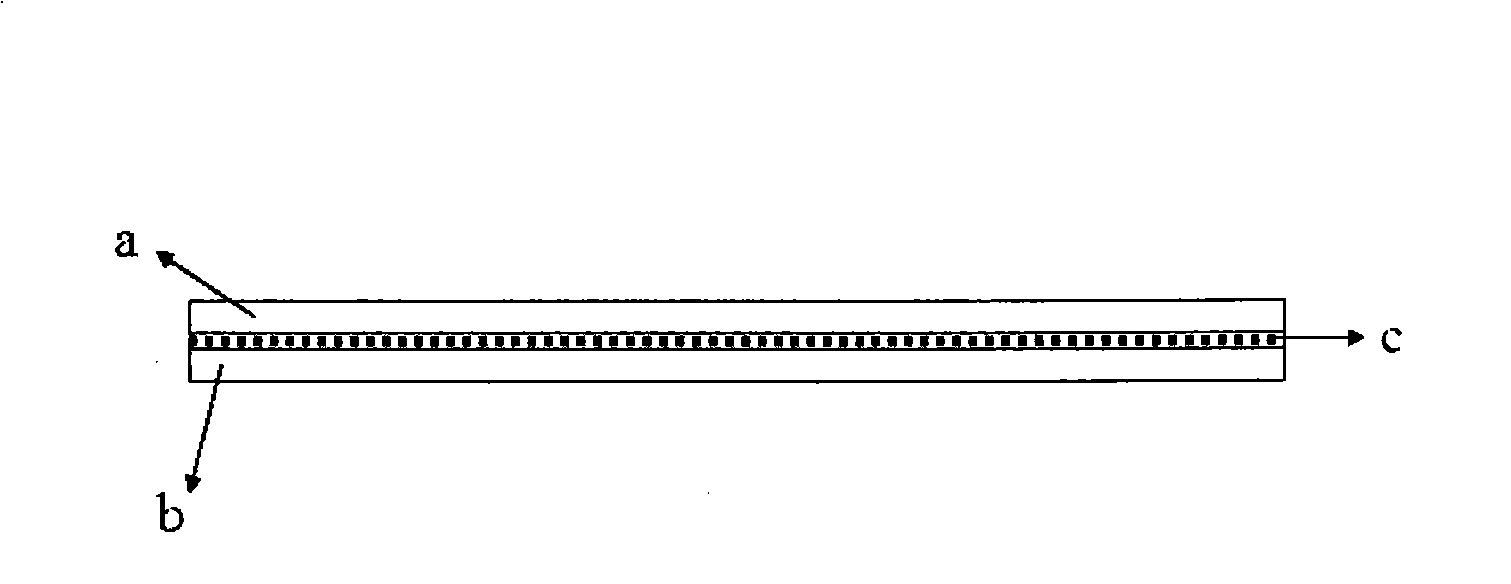

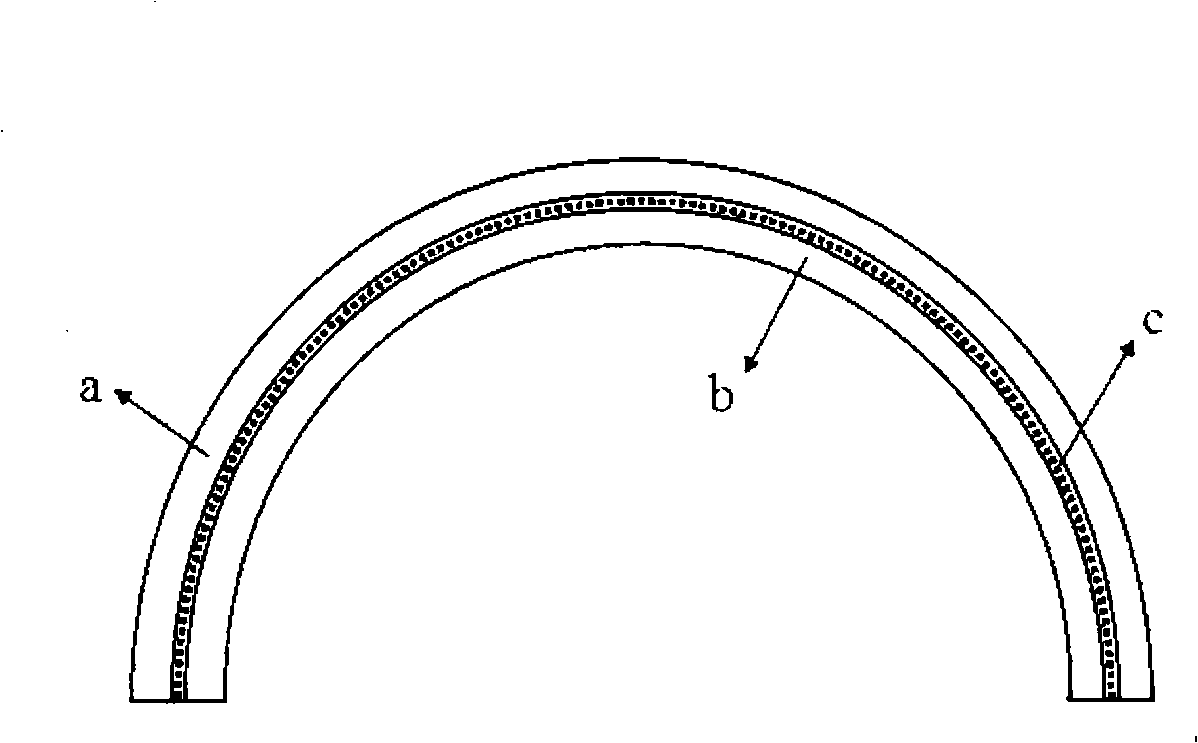

[0038] ②Processing of sapphire and germanate glass

[0039] Process the selected sapphire and germanate glass into components of the desired shape, respectively polish the joint surfaces of the components, and place them in absolute ethanol for ultrasonic cleaning;

[0040] ③ Thermal compounding

[0041] In a clean environment, put the polished surfaces of the components together and place them under high temperature for uniform pressure compounding; the...

Embodiment 1

[0044] Select the mole percentage to divide into 34GeO 2 -12Ga 2 o 3 -6Al 2 o 3 -12BaO-30CaO-6Nb 2 o 5 The main properties and parameters of the germanate glass are shown in glass 1 in Table 1. Then the glass is processed into a disc with a diameter of 20 mm and a thickness of 3 mm, one side of the disc and the sapphire sheet are polished, and then cleaned with absolute ethanol. After drying, put the two wafers together in a clean environment with the cleaned and polished surface directly, then put them into the electric furnace, and keep the wafer load evenly under pressure, with a pressure of 5×10 5 Pa. Raise the temperature at a rate of 5°C / min to 700°C for 8 hours, then cool down to 680°C at a rate of 5°C / min and hold for 6 hours for annealing, and then cool down to room temperature at a rate of 1°C / min.

[0045] After the sample in this example is polished on the surface, the thicknesses of sapphire and germanate glass in the 5mm thick sample are respectively 3mm ...

Embodiment 2

[0047] Select the mole percentage to divide into 60GeO 2 -12Ga 2 o 3 -6Al 2 o 3 -12BaO-5Nb 2 o 5 -5CaO germanate glass, its main property parameters are shown in glass 2 in Table 1. Prepare and process germanate glass and sapphire sheet by the same method as in Example 1, then ultrasonically clean the glass sheet and sapphire sheet with anhydrous alcohol, and then insert a layer of pre-designed and cleaned gold screen between the two After gridding, place it in the electric furnace. A load is applied to the disc to make it evenly compressed, and the pressure is 5×10 5 Pa. Raise the temperature to 690°C at a rate of 5°C / min for 10 hours, then cool down to 620°C at a rate of 5°C / min and hold for 6 hours for annealing, and then cool down to room temperature at a rate of 0.1°C / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com