Method for controlling orientation and profile characteristic of zinc oxide nano-stick/nano-tube array

A nanotube array and nanorod technology, which is applied in the field of synthesizing ZnO nanorods/nanotube arrays, can solve the problems of poor uprightness of one-dimensional ZnO nanostructures, adverse effects of ZnO nanostructures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Prepare the seed layer precursor solution: dissolve zinc acetate and ethanolamine (0.3M) in equimolar amounts into ethanol; after fully stirring for 1 hour, seal and homogenize for 24 hours;

[0046] (2) Clean the deposition substrate: ultrasonically clean and dry the silicate glass substrate one by one with acetone, alcohol, and deionized water;

[0047] (3) Spin-coating precursor solution: place the deposition substrate on a homogenizer, add the prepared seed layer precursor solution dropwise, and spin-coat at a speed of 7500 rpm for 30s;

[0048] (4) Solvent evaporation: transfer the spin-coated substrate to a hot plate at 280° C. for 5 minutes;

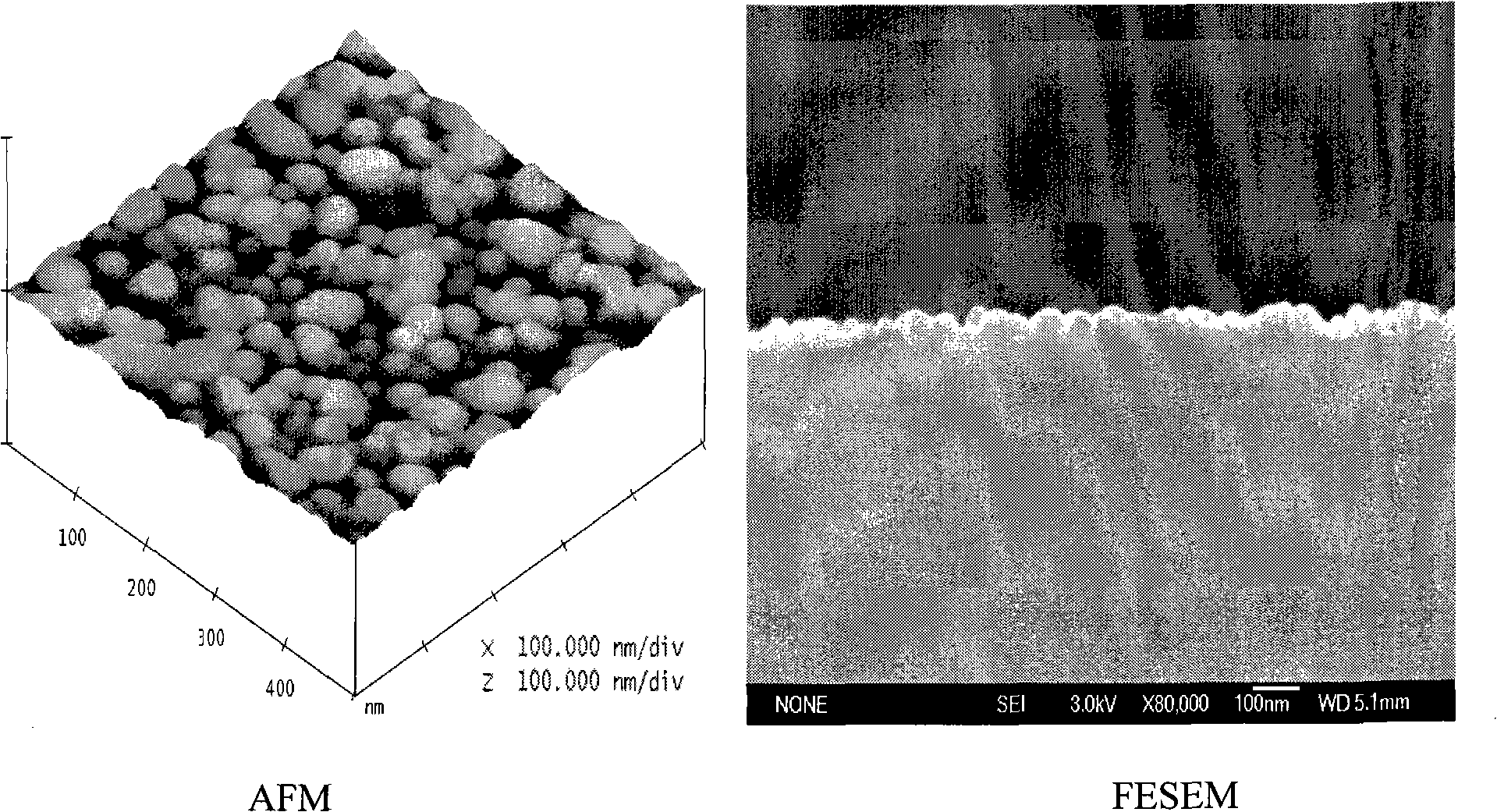

[0049] (5) Transfer to a rapid annealing furnace, first pyrolyze at 300° C. for 10 minutes, and then perform rapid annealing at 500° C. for 5 minutes to obtain a ZnO seed layer. Its surface and cross-sectional morphology are as figure 1 As shown, the seed particles are distributed on the substrate as single particles ...

Embodiment 2

[0053] (1) Prepare the seed layer precursor solution: dissolve zinc acetate and ethanolamine (0.075M) in equimolar amounts into ethanol; after fully stirring for 1 hour, seal and homogenize for 24 hours;

[0054] (2) Clean the deposition substrate: ultrasonically clean and dry the monocrystalline silicon wafers one by one with acetone, alcohol, and deionized water;

[0055] (3) Spin-coating precursor solution: place the deposition substrate on a homogenizer, add the prepared seed layer precursor solution dropwise, and spin-coat at a speed of 3000 rpm for 30s;

[0056] (4) Solvent evaporation: transfer the spin-coated substrate to a hot plate at 280°C for 10 minutes;

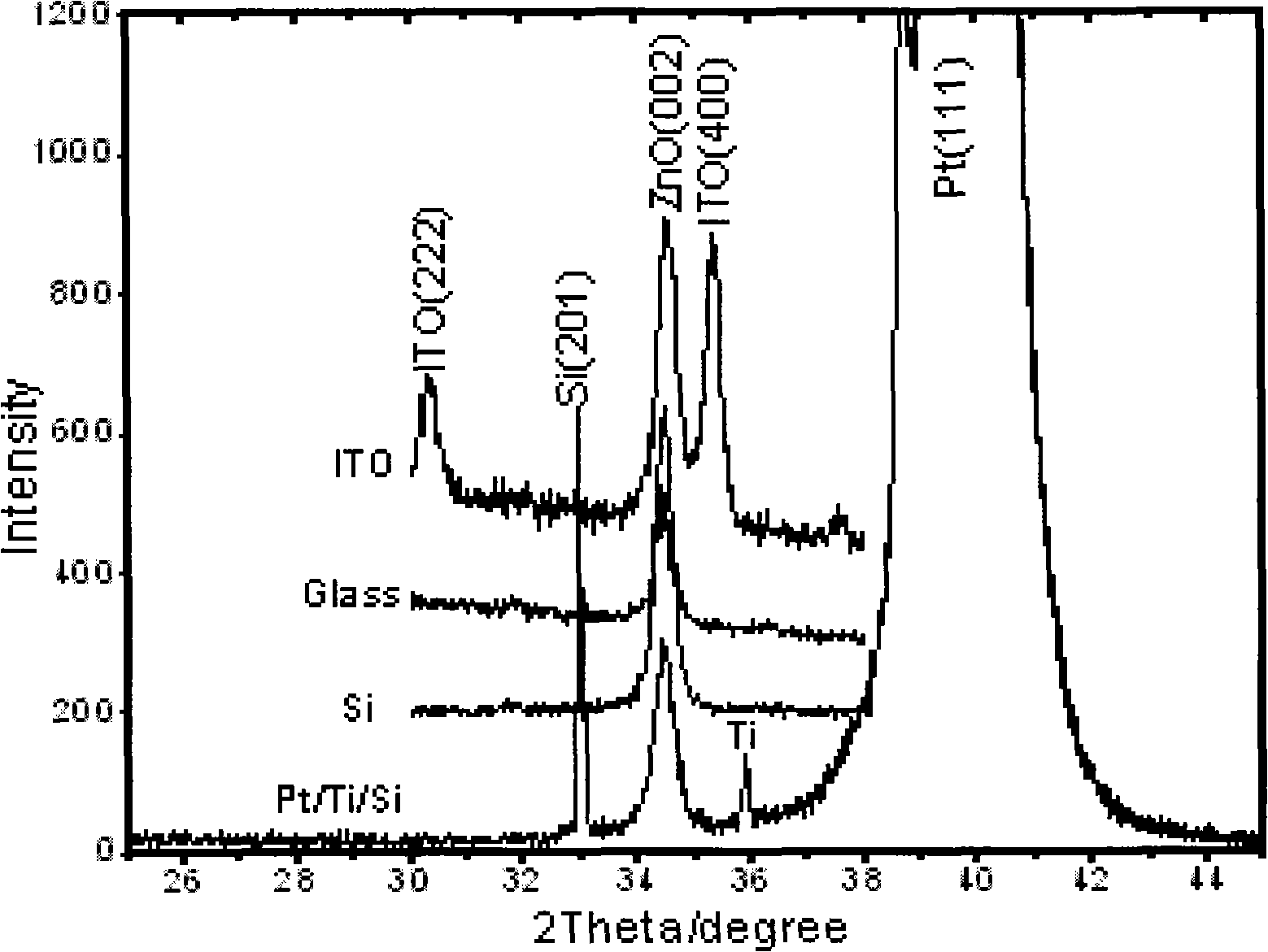

[0057] (5) Transfer to a rapid annealing furnace, first treat at 300°C for 10 minutes, and then rapidly anneal at 500°C for 5 minutes. Figure 4 Middle P2 is the XRD spectrum of the obtained ZnO seed layer film. The seed layer is randomly oriented in (001), (100) and (101) directions;

[0058] (6) The randomly...

Embodiment 3

[0061] (1) Prepare the seed layer precursor solution: dissolve zinc acetate and ethanolamine (0.15M) in equimolar amounts into ethanol; after fully stirring for 1 hour, seal and homogenize for 24 hours;

[0062] (2) Clean the deposition substrate: ultrasonically clean and dry the monocrystalline silicon wafer substrate one by one with acetone, alcohol, and deionized water;

[0063] (3) Spin-coating precursor solution: place the deposition substrate on a homogenizer, add the prepared seed layer precursor solution dropwise, and spin-coat at a speed of 4500 rpm for 30s;

[0064] (4) Transfer the spin-coated substrate to a hot plate at 280° C. for 5 minutes;

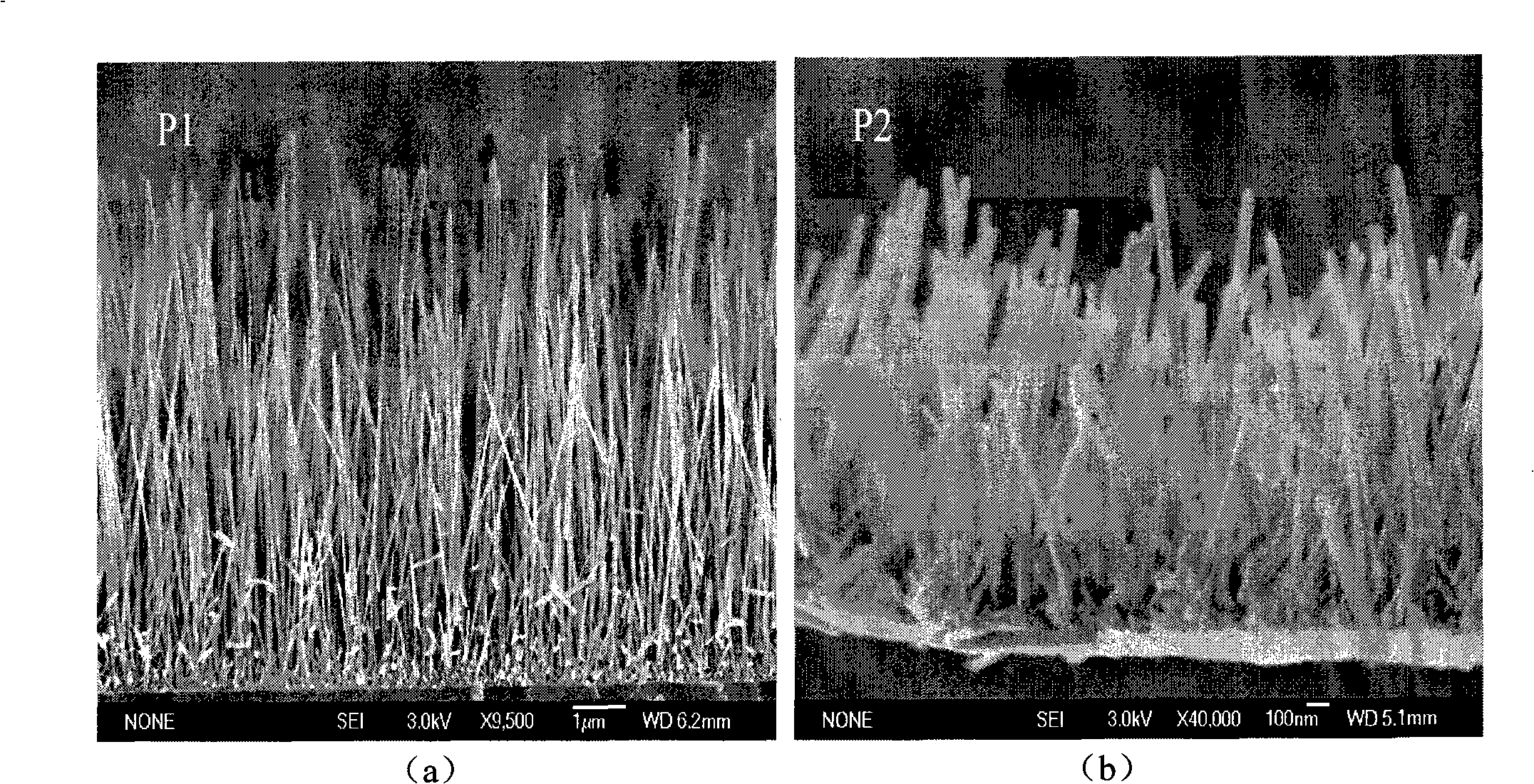

[0065] (5) Transfer to a rapid annealing furnace, first pyrolyze at 300°C for 10 minutes, and then heat treat at 500°C and 650°C for 5 minutes respectively. Figure 5 FESEM images of the surface (a) and cross-section (b) of the obtained seed layer. It can be seen that after high temperature growth, the seed size increases ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com