Regenerated particle aggregate, process for producing regenerated particle aggregate, regenerated-particle-aggregate-containing paper containing regenerated particle aggregate as internal additive, an

A manufacturing method and technology of agglomerates, applied in chemical instruments and methods, waste addition, inorganic compound addition, etc., can solve the problems of great quality change, uneven particle size and enlargement of clay, and achieve good ink adhesion, High optical refractive index and excellent dispersion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

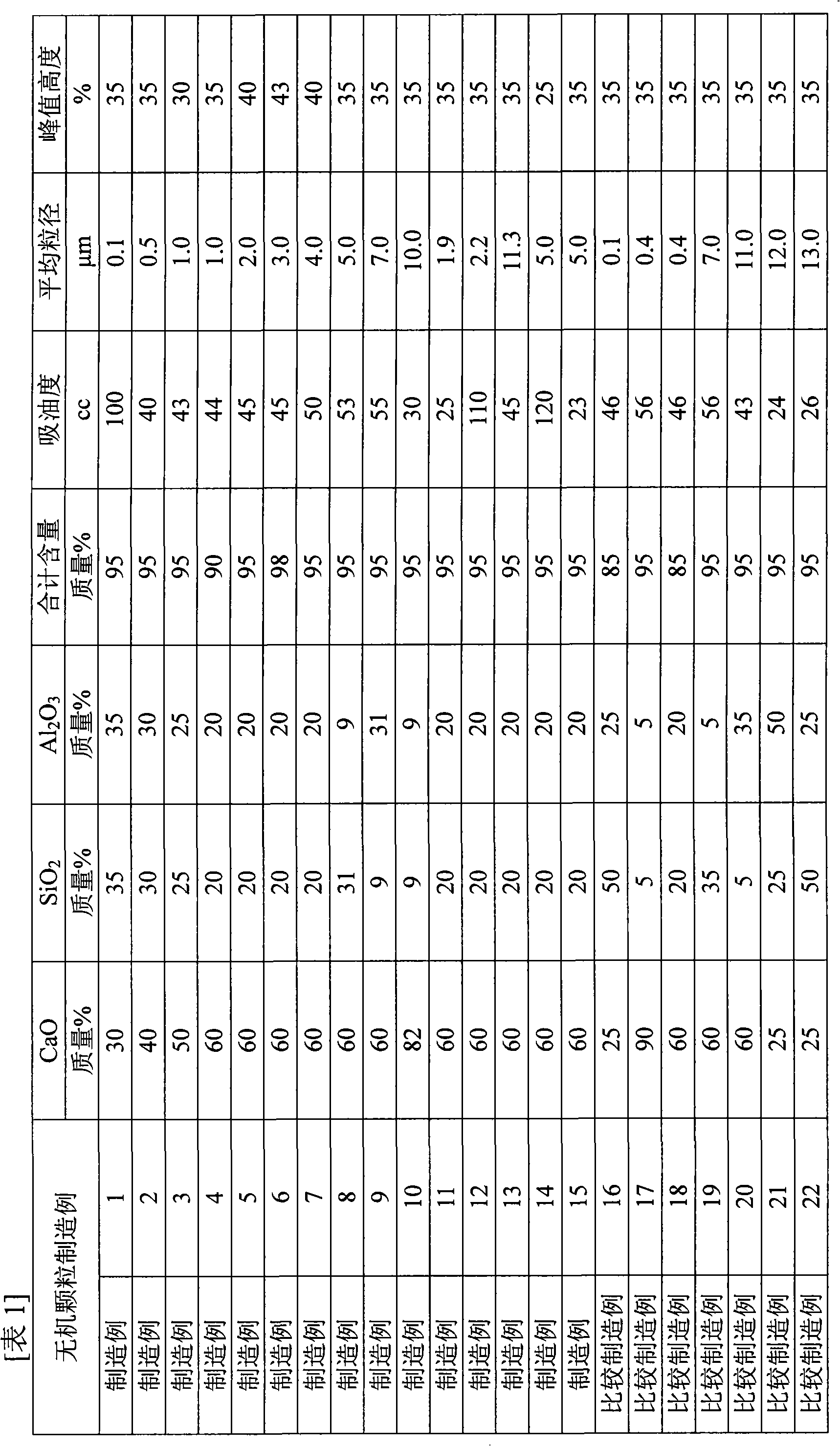

[0203] The following examples will be given to describe the present invention more specifically, but the present invention is not limited to these examples.

[0204]

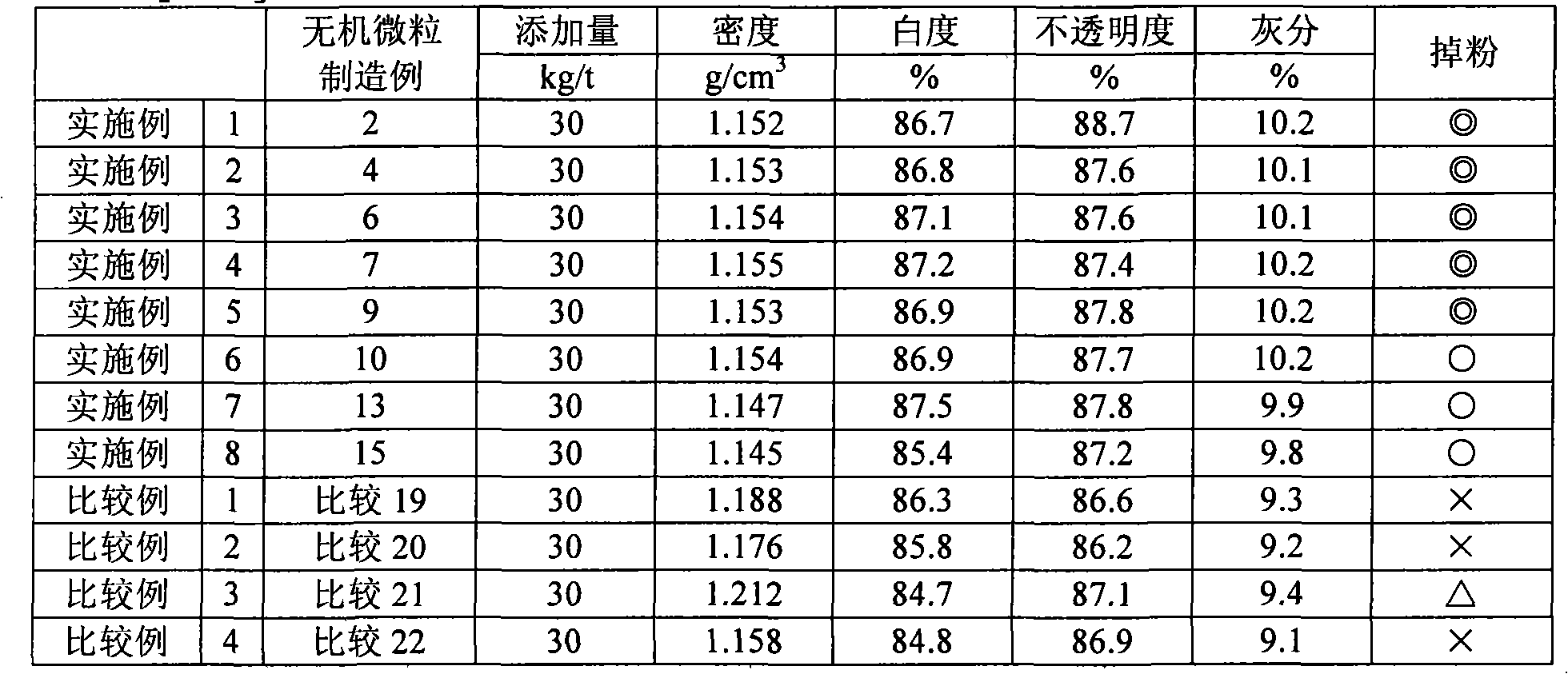

[0205] The characteristics of the regenerated particle agglomerates given in Table 1 in the production examples were studied, and for some of them, BPGW (30 mass %), NBKP (30 mass %), LBKP (25 mass %), DIP (15 mass %) The raw material pulp is added as shown in Table 2, and the weight of the obtained paper is 64g / m 2 The properties of the paper were studied.

[0206] The evaluation method is as follows.

[0207] (1) Measurement of oil absorption: measured in accordance with JIS K 5101.

[0208] (2) Measurement of average particle size and particle size distribution: Add 10 mg of sample to 8 ml of methanol solution, and disperse for 3 minutes with an ultrasonic disperser (output power: 80 watts). The solution was measured using a Coulter counter particle size distribution measuring device (TA-II type manufact...

Embodiment 47

[0265] First, a regenerated particle aggregate is produced according to claim 5 of the invention of the present application.

[0266] Then, as a pigment, 20 parts by weight of regenerated particle aggregates, 50 parts by weight per 100 parts by weight of all pigments, Parts by weight of heavy calcium carbonate (average particle diameter 1.4 μm) and 30 parts by weight of clay (average particle diameter 0.8 μm) relative to all 100 parts by weight of pigment, as a binder, mixed relative to all 100 parts by weight of pigment 5 parts by weight of styrene-butadiene emulsion (acrylonitrile content: 5% by weight, Tg: -10°C, average particle diameter: 130nm, gel content: 85%), mixed with respect to all 100 parts by weight of the pigment 5 parts by weight of urea phosphate starch, mixed with 0.08 parts by weight of acrylic acid-acrylamide copolymer relative to all 100 parts by weight of the pigment, and dispersed to prepare a coating solution for the upper side with a solid content conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com