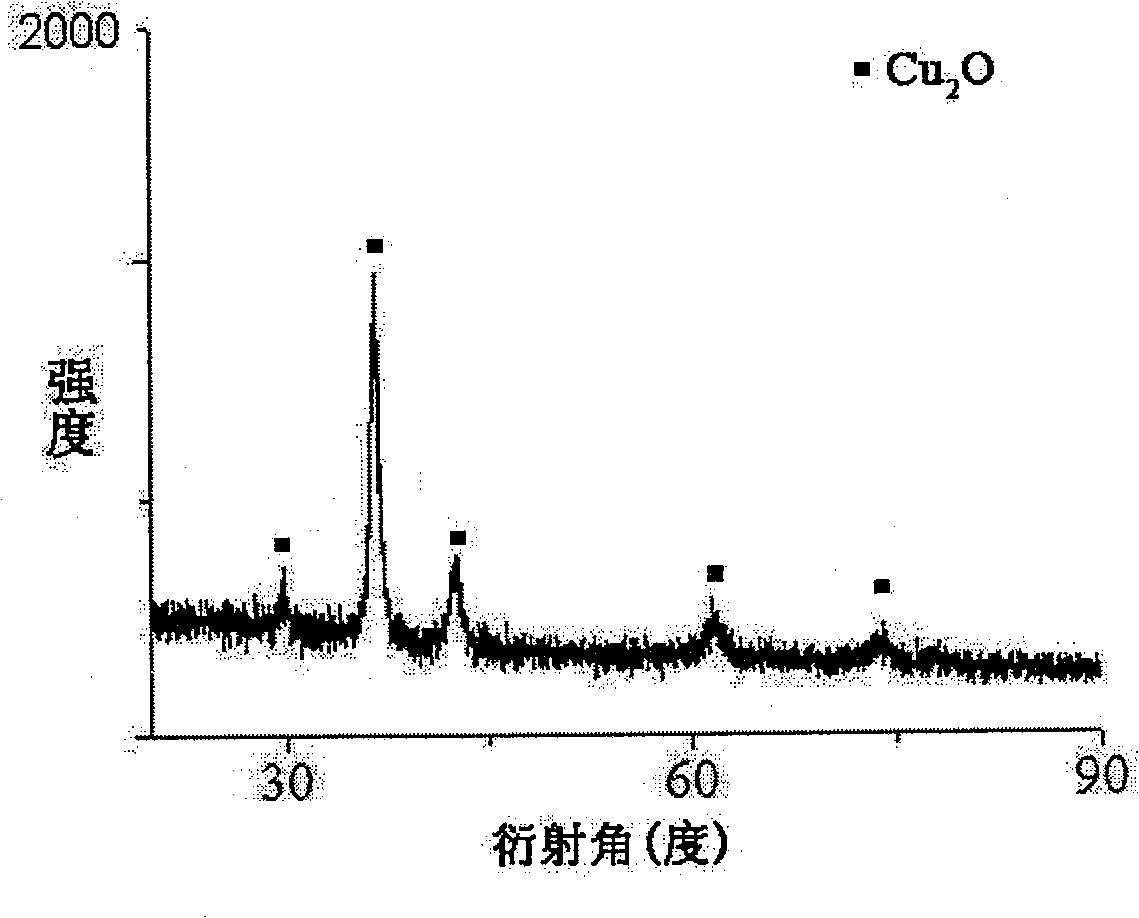

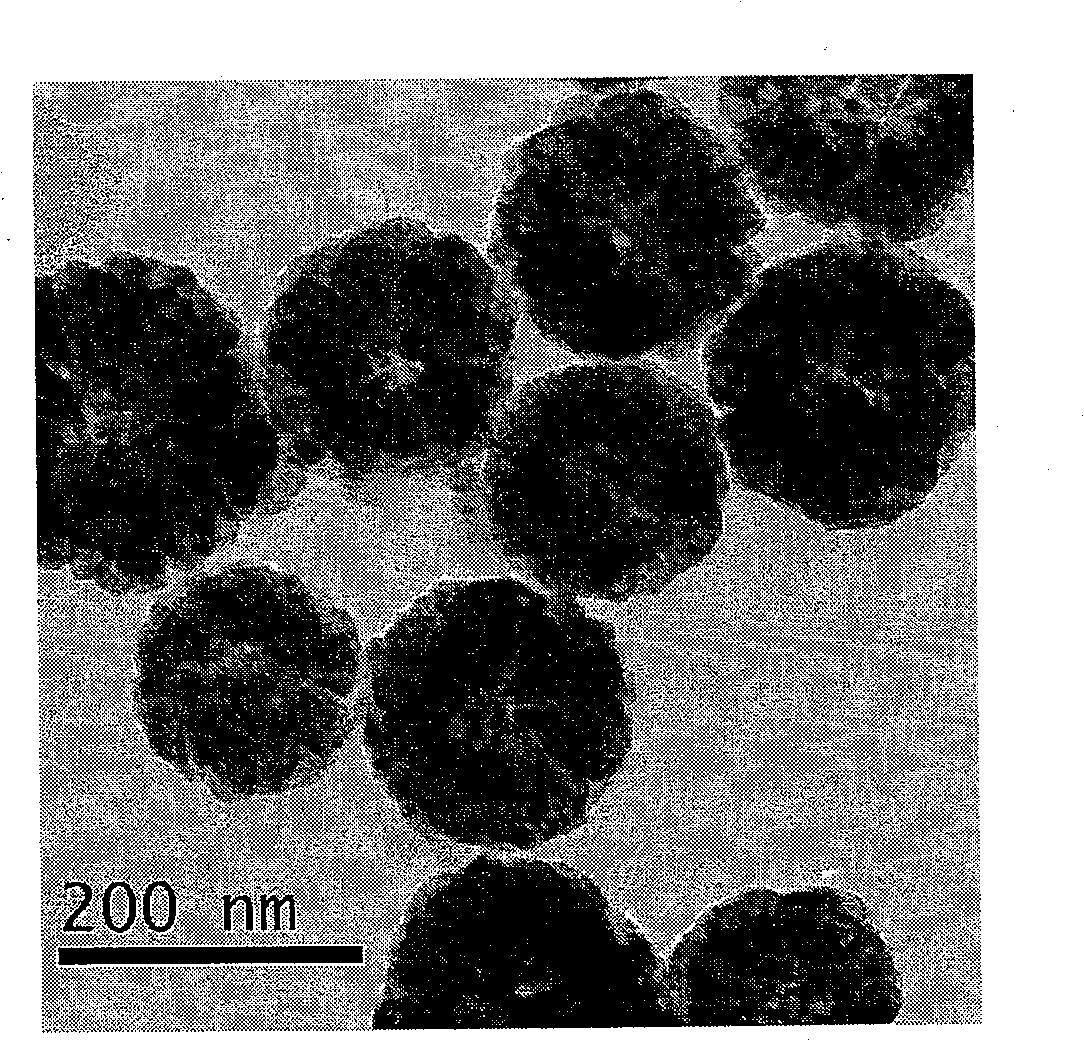

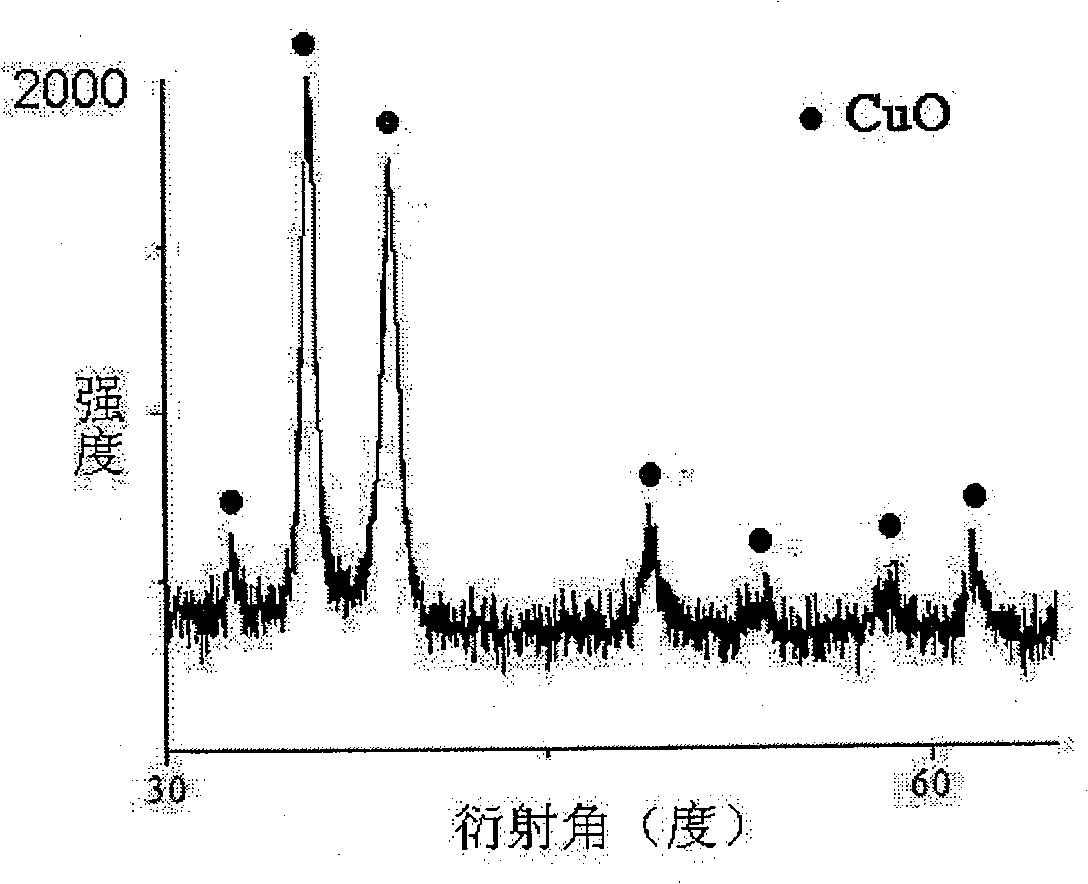

Method for preparing Cu2O or CuO hollow submicrospheres with particle diameter controllable by water phase soft template method

A soft template method, hollow technology, applied in the direction of copper oxide/copper hydroxide, etc., can solve the problems of poor structure controllability, limited aggregate shape change mode, etc., and achieve low cost, easy operation and repeatability, and small particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] 1) Add a certain amount of sodium lauryl sulfate and polyvinylpyrrolidone to deionized water, heat to 40°C to fully dissolve and self-assemble into soft clusters, and mix with copper sulfate aqueous solution after the solution is cooled to room temperature, The final concentration ranges of each component in the solution are: copper sulfate 20mmol / L, SDS 45mmol / L, PVP 10g / L;

[0021] 2) The pH value of the mixed solution obtained in step 1) is adjusted to 12 with 2.5mol / L sodium hydroxide solution;

[0022] 3) Add the hydrazine hydrate aqueous solution with a mass concentration of 50% into the mixed solution obtained in step 2) under stirring conditions, so that the final molar ratio of copper ions and hydrazine hydrate is 1:20, and mix them uniformly at a constant temperature of 50 ° C. React in a water bath for 55 minutes to obtain orange-yellow Cu 2 O colloidal solution, after centrifugation to obtain a precipitate, the precipitate was washed with deionized water an...

Embodiment 2

[0026] 1) Add a certain amount of sodium lauryl sulfate and polyvinylpyrrolidone to deionized water, heat to 45°C to fully dissolve and self-assemble into soft clusters, and mix with copper nitrate aqueous solution after the solution is cooled to room temperature, The final concentration ranges of each component in the solution are: copper nitrate 15mmol / L, SDS 25mmol / L, PVP 10g / L;

[0027] 2) The pH value of the mixed solution obtained in step 1) is adjusted to 11 with 2.5mol / L sodium hydroxide solution;

[0028] 3) Add the hydrazine hydrate aqueous solution with a mass concentration of 50% into the mixed solution obtained in step 2) under stirring conditions, so that the final molar ratio of copper ions and hydrazine hydrate is 1:15, and mix it uniformly at a constant temperature of 50 ° C. React in a water bath for 55 minutes to obtain orange-yellow Cu 2 O colloidal solution, after centrifugation to obtain a precipitate, the precipitate was washed with deionized water and ...

Embodiment 3

[0031] 1) Add a certain amount of sodium lauryl sulfate and polyvinylpyrrolidone to deionized water, heat to 55°C to fully dissolve and self-assemble into soft clusters, and mix with copper acetate aqueous solution after the solution is cooled to room temperature, The final concentration ranges of each component in the solution are: copper acetate 15mmol / L, SDS 9mmol / L, PVP 8g / L;

[0032] 2) The pH value of the mixed solution obtained in step 1) is adjusted to 11 with 2.5mol / L sodium hydroxide solution;

[0033]3) Add the hydrazine hydrate aqueous solution with a mass concentration of 50% into the mixed solution obtained in step 2) under stirring conditions, so that the final molar ratio of copper ions and hydrazine hydrate is 1:15, and mix it uniformly at a constant temperature of 40 ° C. React in a water bath for 65 minutes to obtain orange-yellow Cu 2 O colloidal solution, after centrifugation to obtain a precipitate, the precipitate was washed with deionized water and abs...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com