Process for producing high-quality granular bisphenol A

A high-quality, granular technology, applied in the preparation of organic compounds, organic chemical methods, chemical instruments and methods, etc., can solve problems such as metal powder abnormalities, quality problems, and rust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] Hereinafter, the present invention will be described in further detail through examples, but the present invention is not limited by these examples.

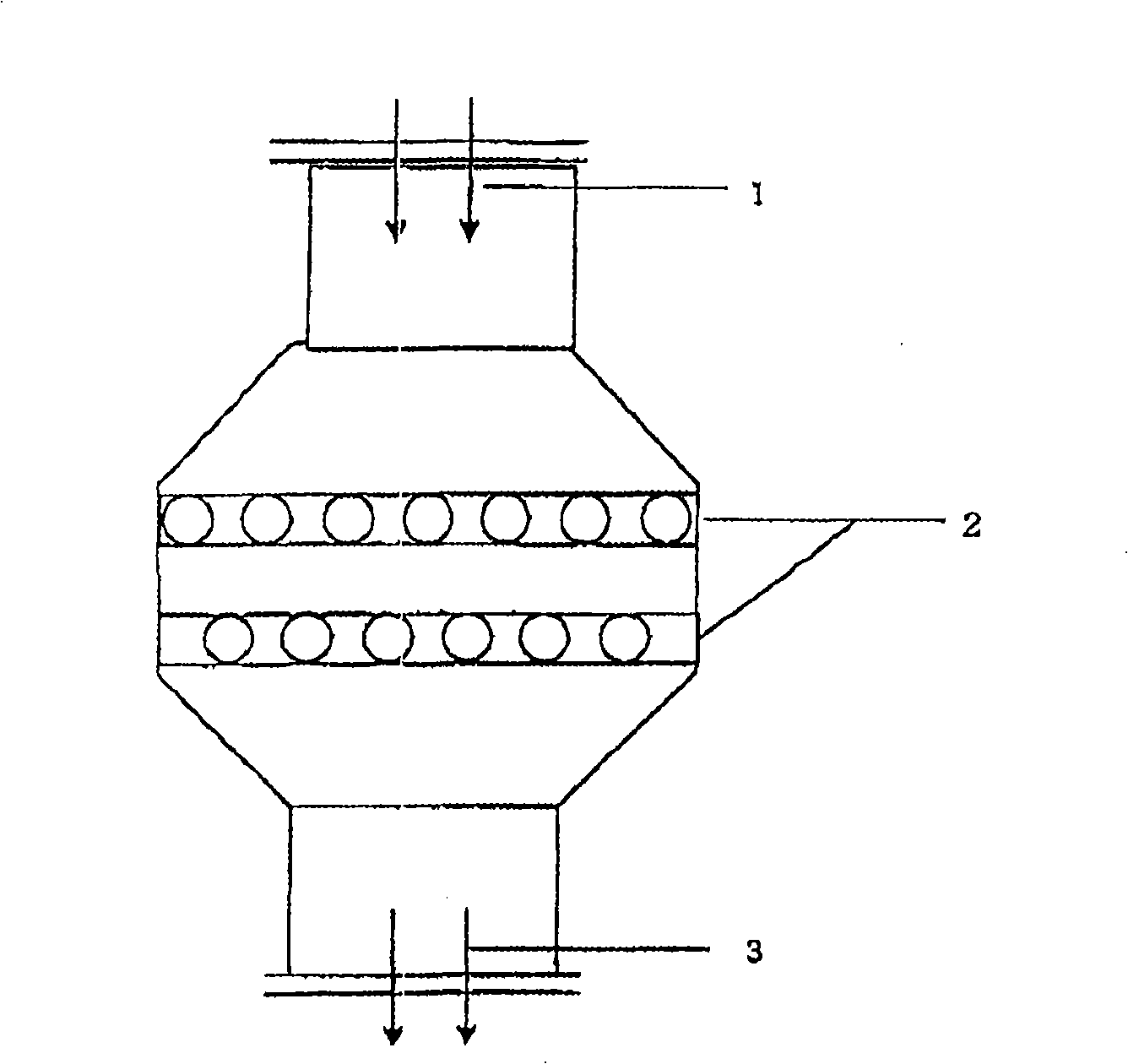

[0076] Reference example

[0077] Using 2-mercaptoethylamine, the sulfonic acid groups of the cation exchange resin [manufactured by Mitsubishi Chemical Co., Ltd., "Daiyaion SK104H"] were partially neutralized by 20% mol, and the resulting catalyst was packed in a fixed-bed reaction tower, 3 hours at LHSV -1 Phenol and acetone (phenol: 32 tons / hour, acetone: 3 tons / hour) were continuously fed thereinto, and the reaction was carried out at 75°C. The resulting reaction mixture is introduced into a vacuum distillation tower, and is distilled under reduced pressure at a temperature of 170°C at the bottom of the tower and a pressure of 67kPa-A to remove acetone, water, etc. Press distillation, distill off phenol, be concentrated to the concentration of bisphenol A and be 40% mass, obtain the bisphenol A / phenol solution of 15...

Embodiment 1

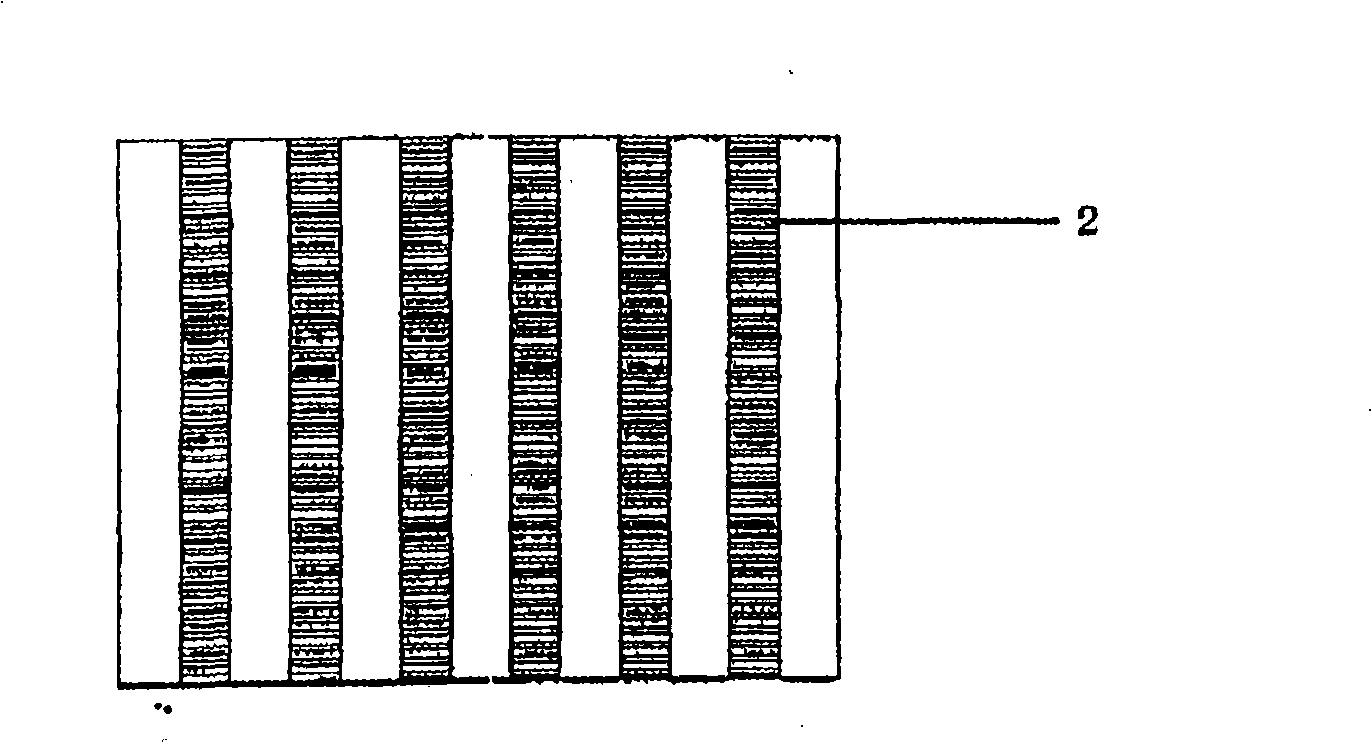

[0084] The granular bisphenol A obtained in the above reference example was transported to the finished product warehouse at 4.3 tons / hour through a rotary valve (rotary blade: made of stainless steel) and a bucket conveyor (bucket: made of stainless steel, internal chain: made of iron). A metal trapping part is installed at the entrance of the finished product silo, and the metal trapping part passes a rod-shaped magnet (neodymium rare earth type, surface magnetic flux density: 0.9 tesla) inserted into a stainless steel tube with a diameter of 25 mm and a length of 40 cm and a stainless steel tube. Install two layers with an interval of 50mm (layer interval: 60mm), and measure the iron content of the finished granular bisphenol A sampled at the outlet of the finished product warehouse. Minutes, use the APHA standard color to visually evaluate the hue, and the result is APHA15.

Embodiment 2

[0086] A metal trapping part is arranged at the entrance of the finished product bin. The metal trapping part is obtained by inserting a magnet with a surface magnetic flux density of 0.7 Tesla in a stainless steel tube and installing the obtained rod-shaped magnet in two layers. In addition, it is the same as the embodiment 1 Granular bisphenol A was prepared in the same manner. Measure the iron content of the finished granular bisphenol A sampled at the outlet of the finished product warehouse, the content is 0.1ppm by mass, heat the bisphenol A at 220°C for 40 minutes in an air atmosphere, and use the APHA standard color to visually evaluate the hue, the result for APHA 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com