Preparation technique of micropore titanium plate

A preparation process and technology of microporous titanium, which is applied in the field of titanium plate processing, can solve the problem of inaccurate thickness control, etc., and achieve the effects of easy control of aperture ratio, low processing cost and low rolling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

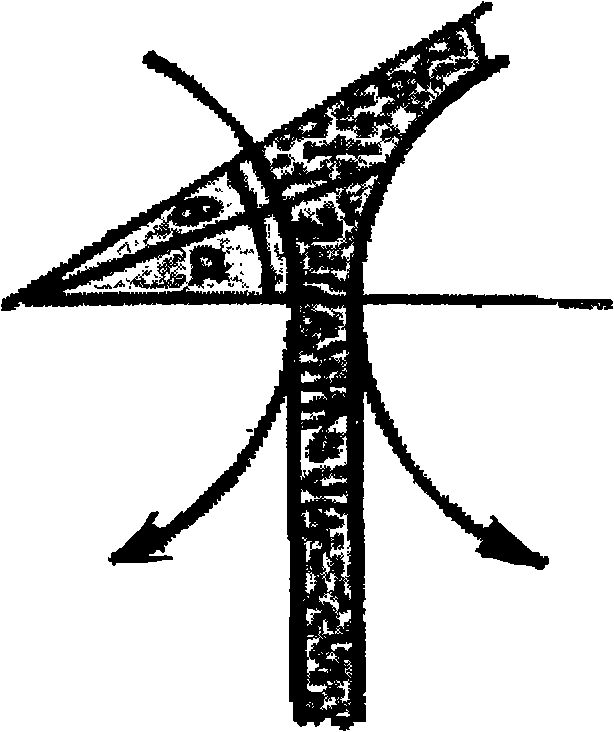

Image

Examples

Embodiment Construction

[0025] The preparation process of the microporous titanium plate is implemented according to the following steps:

[0026] (1) Milling: select sponge titanium, and use hydrodehydrogenation method to extract high-purity titanium powder with low oxygen and low hydrogen; the oxygen content of high-purity titanium powder is less than 0.05%, and the hydrogen content is less than 0.02%. The content is not less than 99.75%;

[0027] (2) Powder selection: use a magnetic separator to remove iron-containing impurities in the titanium powder, and use a screening machine to classify the titanium powder according to the particle size;

[0028] (3) Cleaning treatment: pickling the graded titanium powder to remove metal and non-metallic impurities and then washing with pure water; pickling adopts nitric acid with a concentration greater than 15%.

[0029] (4) Drying: vacuum and dust-free drying of the cleaned titanium powder;

[0030] (5) Preparation and classification: the titanium powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com