Lithium ion super capacitor and assembling method thereof

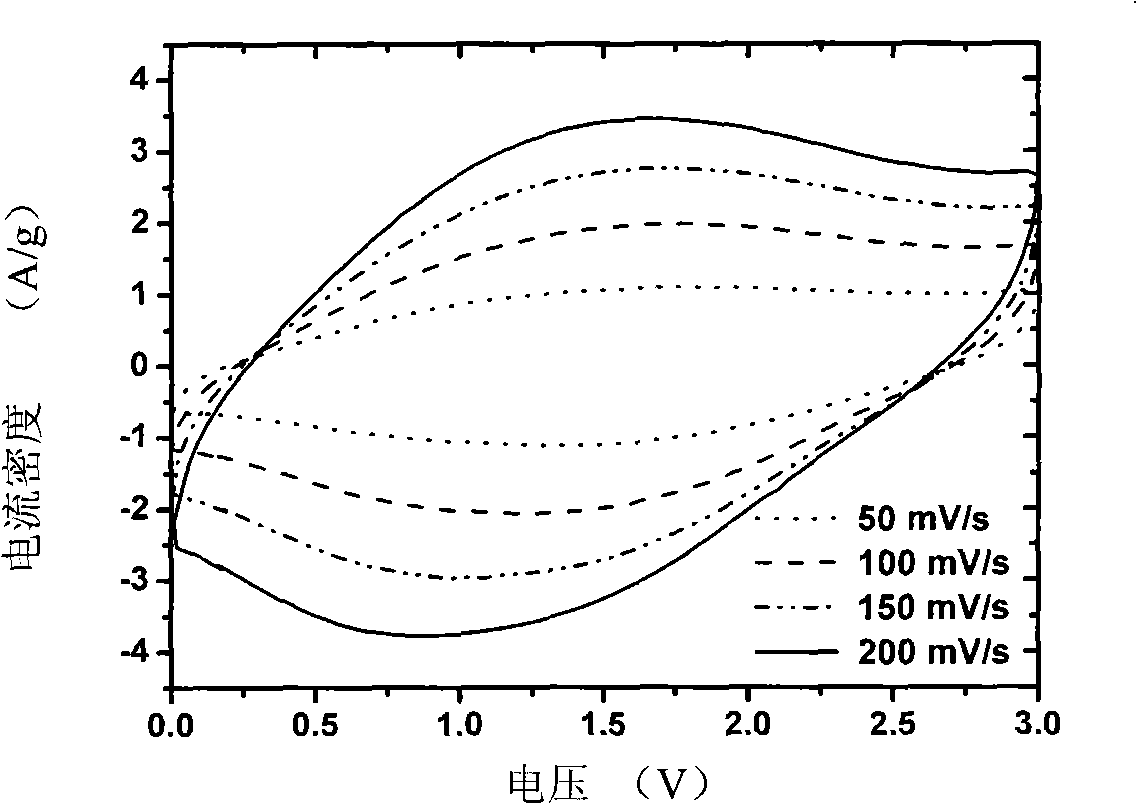

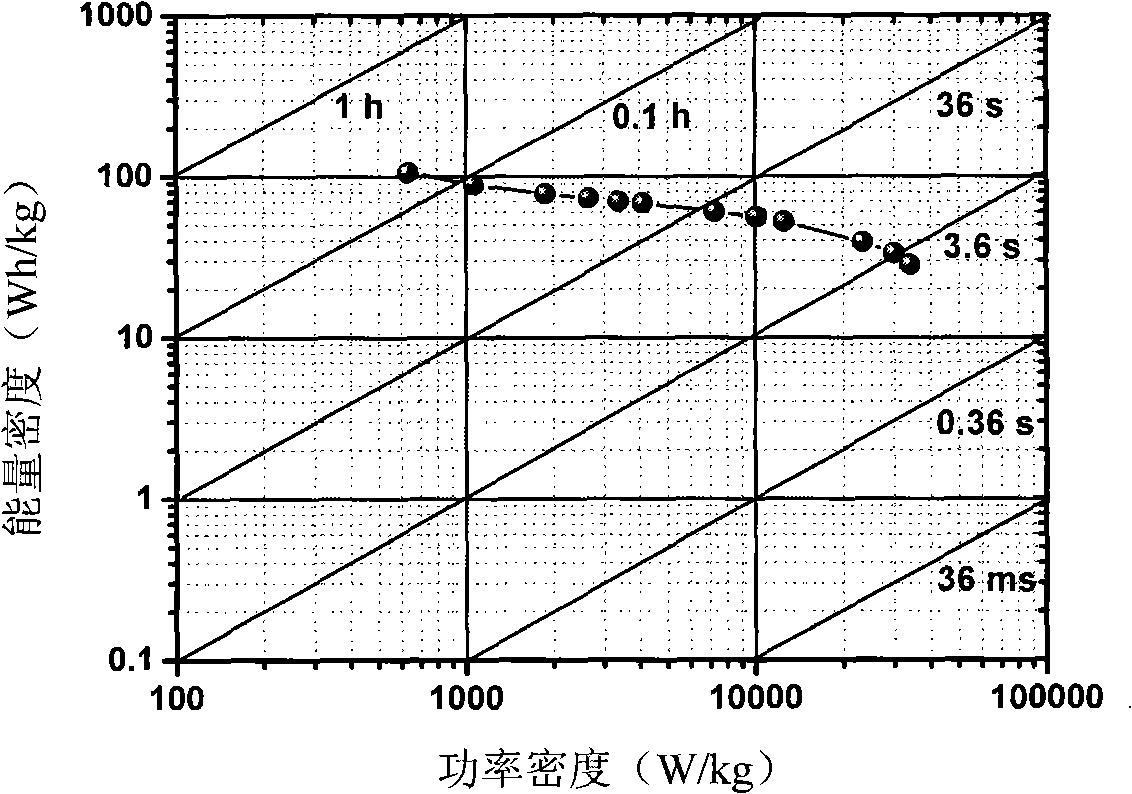

A technology of supercapacitor and assembly method, applied in capacitors, electrolytic capacitors, capacitor parts and other directions, can solve the problems of low energy density of supercapacitors, and achieve the effect of improving power density, improving power density and high power characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The titanium oxide nanotube substrate was cut into a suitable size (1.1 cm×0.8 cm), and the mass of the titanium oxide nanotube was calculated from the apparent area to be 0.1264 mg, washed with acetone and dried in vacuum.

[0024] According to the active electrode material (the mesopore carbon pore diameter is 3-6nm, by volume ratio, the mesopore accounts for 45%, and the rest are micropores): binder (polytetrafluoroethylene PTFE): the quality of conductive agent (acetylene black) The ratio is 90:5:5 The electrode material with a total mass of 100 mg is weighed, dispersed in 1 ml of absolute ethanol, ground, mixed evenly, and vacuum-dried to prepare a composite electrode material. Weigh a composite electrode material containing 2 mg of active electrode material, wet it with absolute ethanol (about 2 ml), apply it to the surface of the foamed nickel collector, and dry it in vacuum.

[0025] Titanium oxide nanotube substrate and mesoporous carbon foamed nickel electrode...

Embodiment 2

[0031] The difference from Example 1 is:

[0032] The titanium oxide nanotube array substrate was cut into a suitable size (1 cm×1 cm), and the mass of the titanium oxide nanotubes was calculated from the apparent area to be 0.1342 mg, washed with acetone and dried in vacuum.

[0033] According to the mass ratio of active electrode material (activated carbon, micropore ratio 76%, the rest is mesopore): binder (PTFE): conductive agent (single-walled carbon nanotube) is 85: 5: 10 and the weighing total mass is 100mg The electrode material was dispersed in 1ml of absolute ethanol, ground, mixed evenly, and prepared into a composite electrode material after vacuum drying. Weigh a composite electrode material containing 2 mg of active electrode material, wet it with absolute ethanol (about 2 ml), apply it to the surface of the foamed nickel collector, and dry it in vacuum.

[0034] The titanium oxide nanotube array substrate and the activated carbon foamed nickel electrode were re...

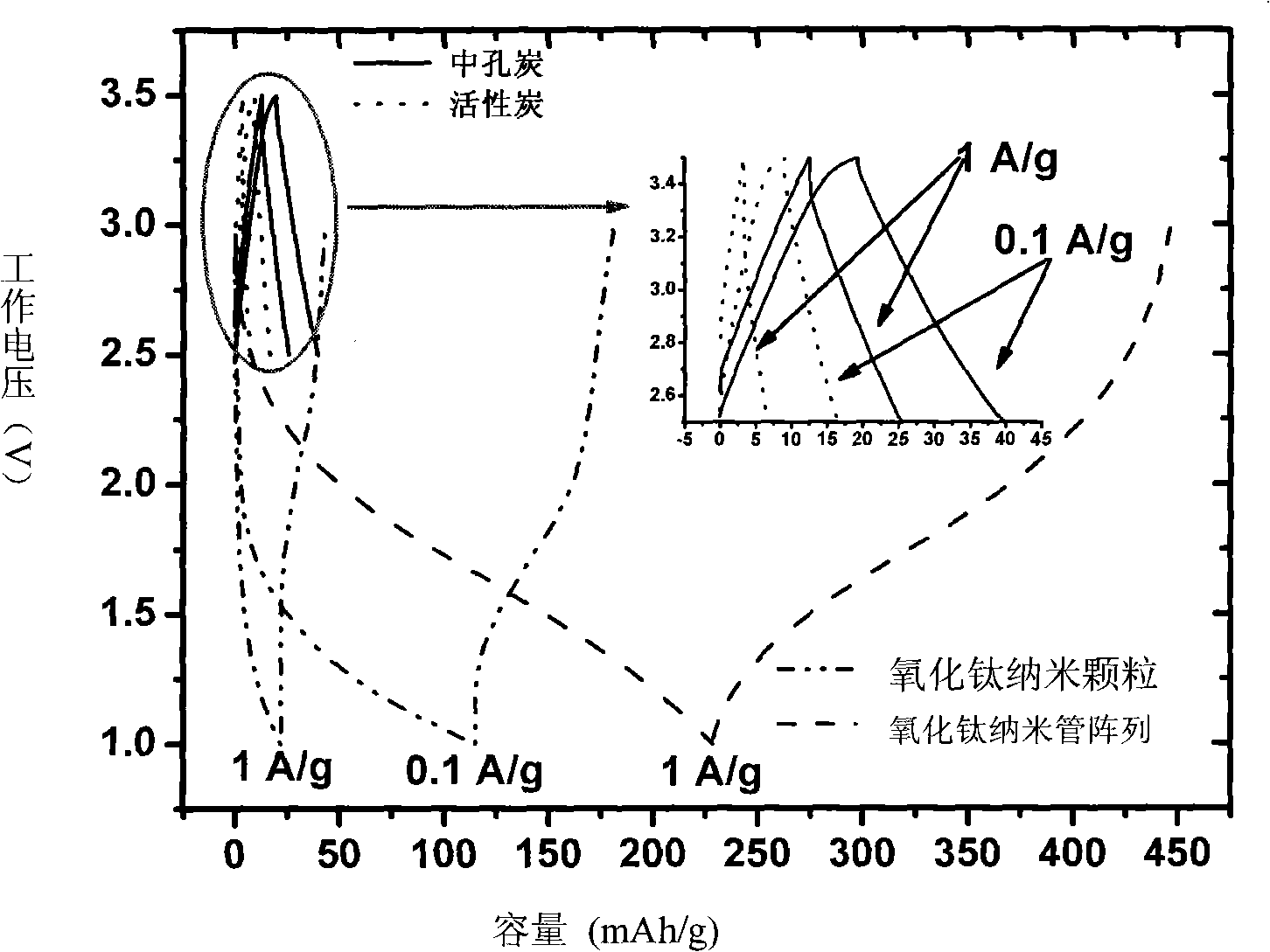

Embodiment 3

[0039] The difference from Example 1 is:

[0040] According to the active electrode material (mesoporous carbon or titanium oxide nanoparticles, the pore diameter of mesoporous carbon is 3-5nm, by volume ratio, mesopores account for 50%, and the rest are micropores; the specification of titanium oxide nanoparticles is 10-50nm): Binder (PVDF): The mass ratio of conductive agent (multi-walled carbon nanotubes) is 80:10:10 Weigh the electrode material with a total mass of 100mg, disperse in 1ml of absolute ethanol, grind, mix evenly, and vacuum dry Then prepare composite electrode materials. Weigh a composite electrode material containing 2 mg of active electrode material, wet it with absolute ethanol (about 2 ml), apply it to the surface of the foamed nickel collector, and dry it in vacuum.

[0041] The foamed nickel electrodes of mesoporous carbon and titanium oxide nanoparticles were respectively used as the counter electrode of lithium metal, and assembled into a half-cell t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com