Continuous hydrolyzation method for cellulose series biomass and apparatus thereof

A cellulose and hydrolysis device technology, applied in the field of biomass, can solve the problems of low efficiency, affect the effect of hydrolysis, difficult to apply in engineering, etc., and achieve the effect of improving the hydrolysis effect, continuous operation and good treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

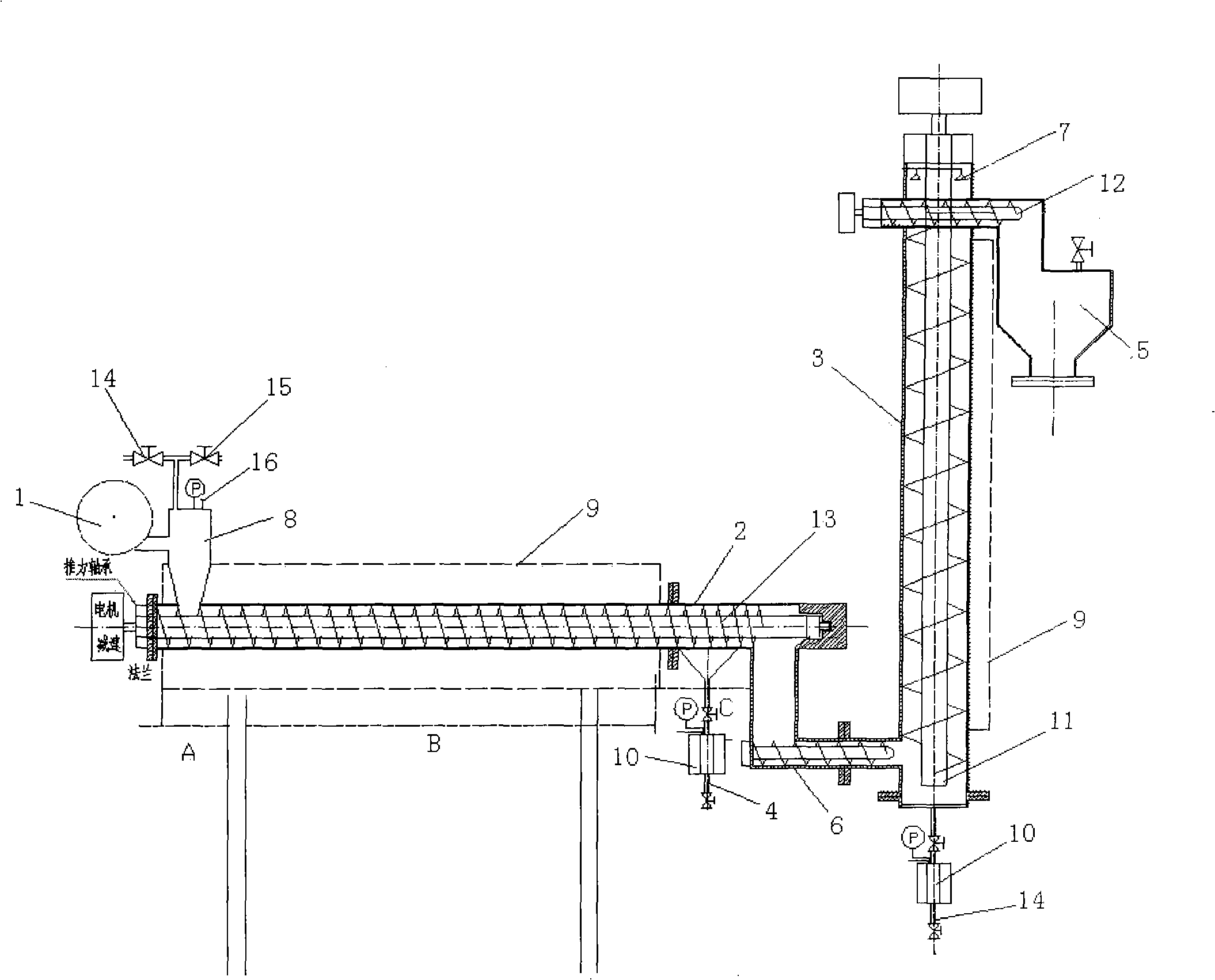

[0032] Such as figure 1 As shown, the device of this embodiment includes a continuous hydrolysis device consisting of a feed system, a biomass hydrolysis reaction system and a product collection system, wherein the feed system is fed to high temperature and high pressure through a spherical air lock device; the reaction system includes semi-fiber Plug-flow reactor for cellulose hydrolysis and vertical counter-current reactor for cellulose hydrolysis; product collection system includes collection of liquid products and solid residues.

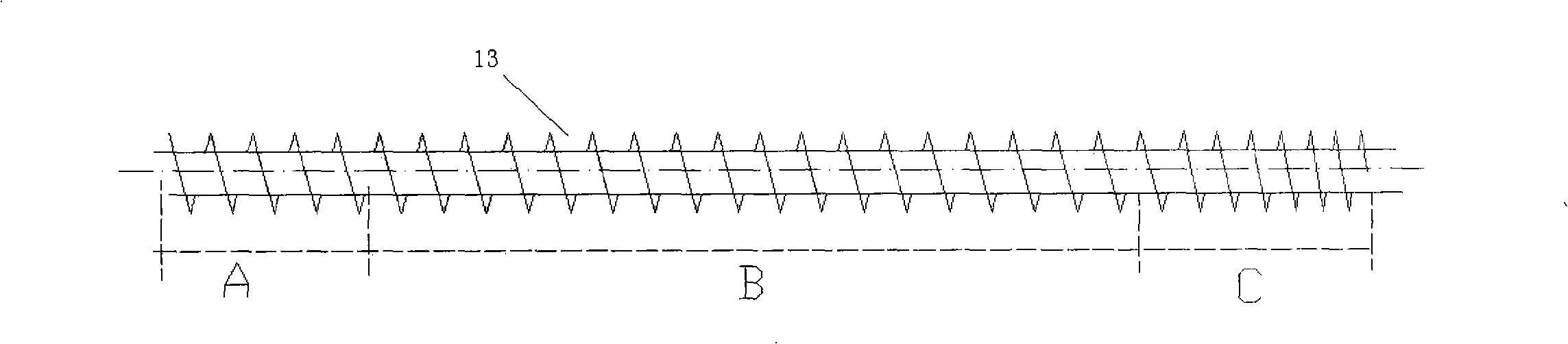

[0033] Specifically, it includes a continuous feeding airlock system 1, a horizontal plug flow reactor 2, and a vertical countercurrent reactor 3. Inside the horizontal plug flow reactor 2 is a variable-pitch helical push rod 13, including a feed section A, a main reaction section B and a squeeze section C. The feed section A is provided with a reactant feed port, which communicates with the continuous feed airlock system 1 , and the squeeze se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com