Method for preparing soybean isoflavone glycoside from soybean isoflavones aglycone

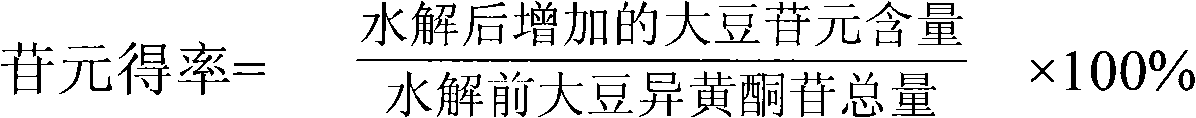

A technology for isoflavone aglycone and isoflavone glycosides, which is applied in the directions of hydrolase, fermentation, etc., can solve the problems of low cost, complicated operation and low enzyme activity, and achieves the effects of high conversion rate, simple extraction and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] a. Chicken gold powder mixed with 0.2M / L, pH 6.0 phosphate buffer at a mass ratio of 1:5, extracted at 4°C for 24 hours, centrifuged to discard the residue, and ammonium sulfate was added to the supernatant to saturation to precipitate the enzyme Protein, collect protein, dissolve in 0.2M / L, pH 6.0 phosphate buffer, dialyze with cellophane bag to remove ammonium sulfate, centrifuge and discard the residue, which is the enzyme solution.

[0037] b. Mix 100 mL of daidzin with a concentration of 10 g / L and 100 mL of the enzyme solution in a. and react at a temperature of 25° C. for 30 hours.

[0038] c. Add 2 times the reaction volume of ethyl acetate to the reaction mixture, fully shake and extract, and let stand to separate layers. The conversion rate of daidzin into daidzein in the reaction product is 97.1%.

Embodiment 2

[0040] a. Chicken gold powder and 0.2M, pH 5.0 acetic acid buffer are mixed at a mass ratio of 1:6, extracted at 4°C for 3 hours, centrifuged to discard the residue, and 3 times the volume of 95% ethanol is added to the supernatant to precipitate the enzyme Protein, the supernatant was discarded by centrifugation, the protein was collected, and dissolved in acetate buffer (0.2M, pH5.0), which was the enzyme solution.

[0041] b. Mix 100 mL of 40 g / L genistin in acetate buffer solution (0.2 M, pH 5.0) and 200 mL of the enzyme solution in a., and react at a temperature of 40° C. for 30 hours.

[0042] c. Add 3 times the reaction volume of ethyl acetate to the reaction mixture, fully oscillate for extraction, and let stand to separate layers. The conversion rate of genistin into genistein in the reaction product was 90.4%.

Embodiment 3

[0044] a. Chicken gold powder and 0.2M, pH6.0 acetic acid buffer are mixed according to the mass ratio of 1:10, extracted at 4°C for 36 hours, centrifuged to discard the residue, and 6 times the volume of 95% ethanol is added to the supernatant to precipitate the enzyme Protein, the supernatant was discarded by centrifugation, the protein was collected, and dissolved in acetate buffer (0.2M, pH7.0), which was the enzyme solution.

[0045] b. Mix 70g / L genistin, 100mL acetate buffer solution (0.2M, pH7.0) and 200mL of the enzyme solution in a., and react at a temperature of 40°C for 18 hours.

[0046] c. Add 3 times the reaction volume of ethyl acetate to the reaction mixture, fully oscillate for extraction, and let stand to separate layers. The conversion rate of genistin into genistein in the reaction product was 93.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com