Osmotic pump controlled release preparation composition and preparation thereof

An osmotic pump controlled release and composition technology, which is applied in the directions of drug combinations, active ingredients of heterocyclic compounds, pharmaceutical formulations, etc., can solve the problem of not mentioning preparation into osmotic pump preparations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

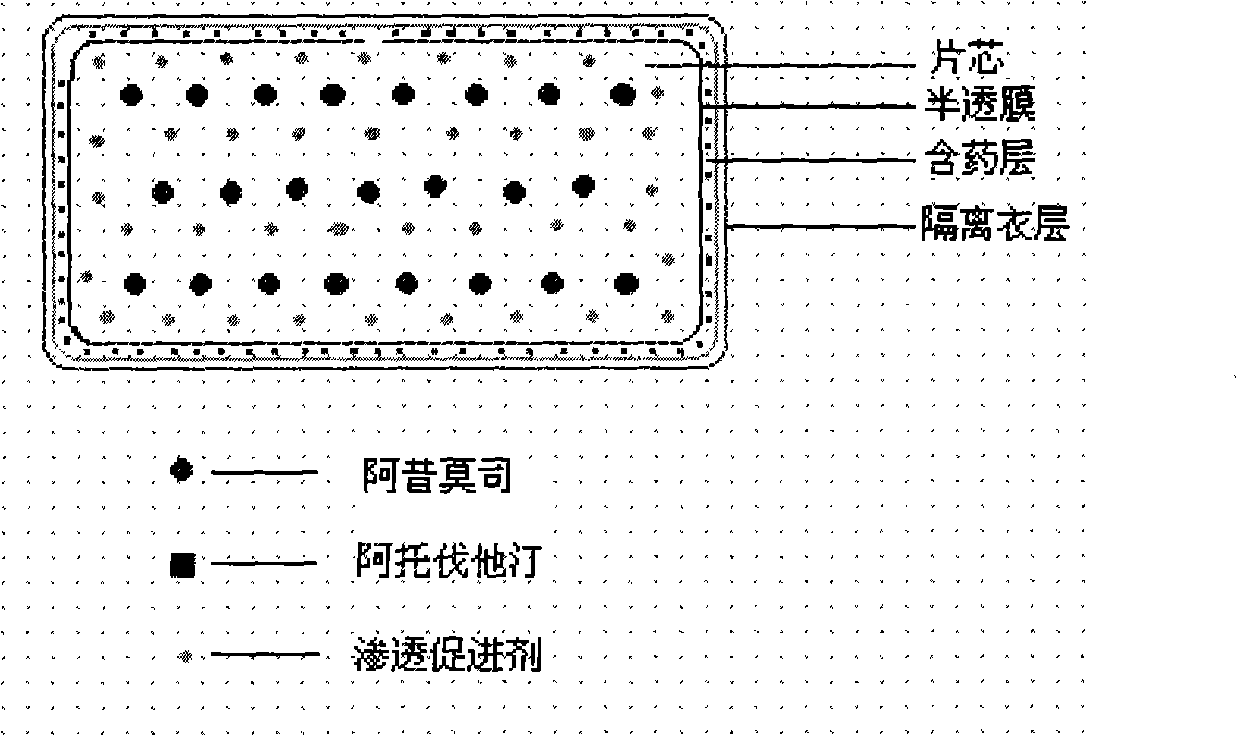

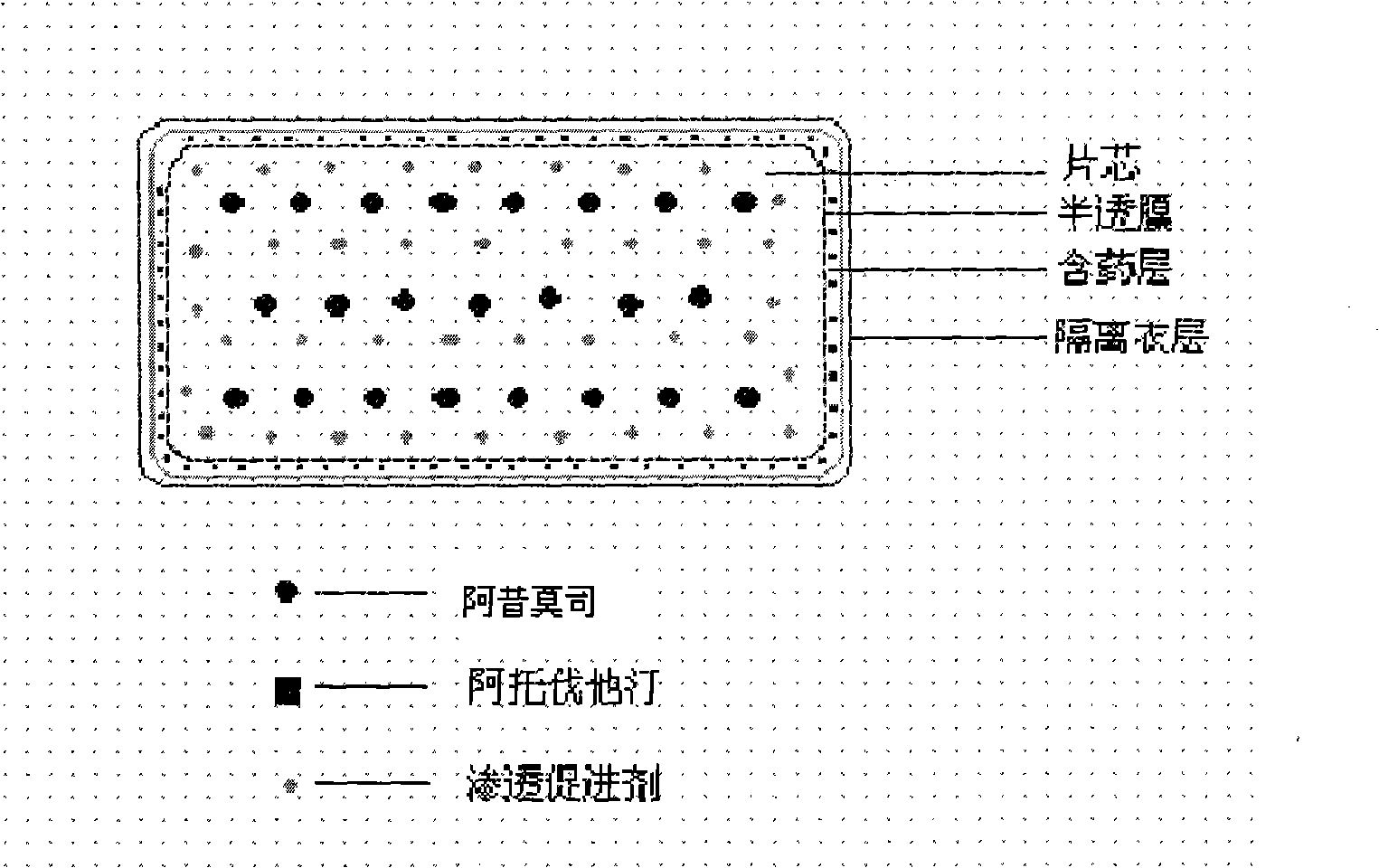

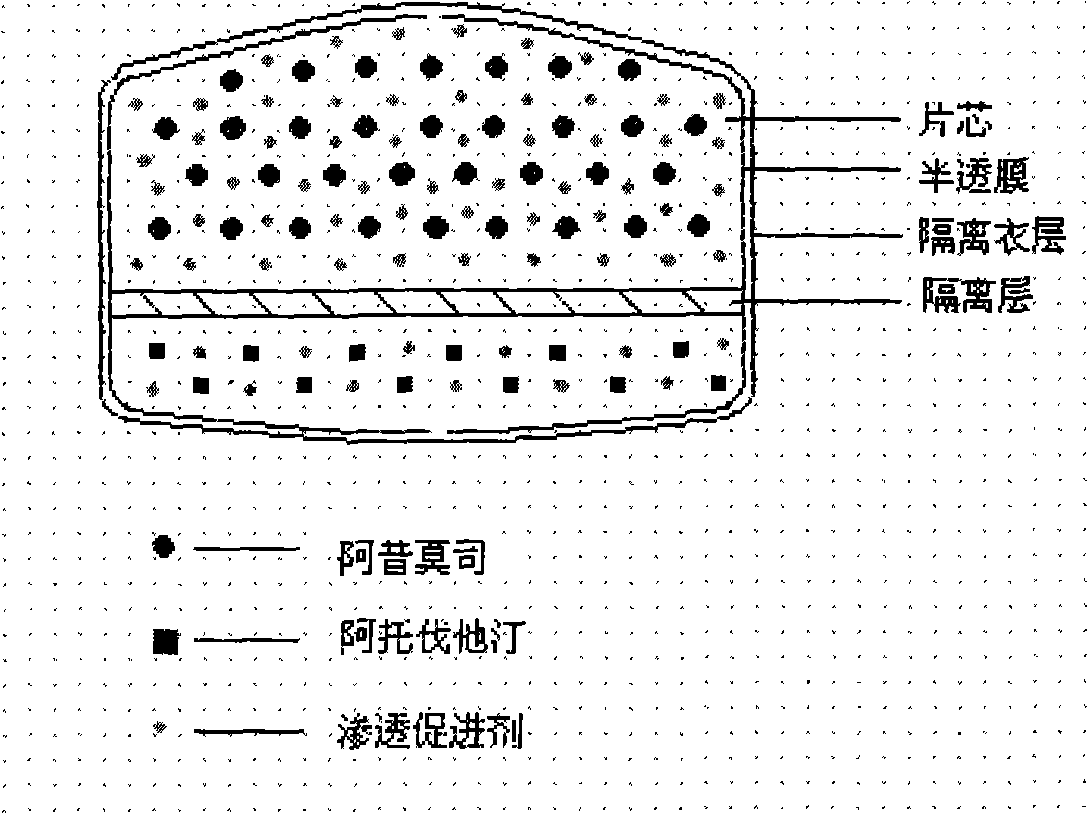

Image

Examples

Embodiment 1

[0086] Chip composition:

[0087] Acipimus 100g

[0088] NaCl 25g

[0089] PVPk30 1.5g

[0091] Coating film composition:

[0092] Cellulose acetate 7g

[0093] Macrogol 4000 3g

[0094] Diethyl phthalate 2g

[0095] Immediate release drug layer composition:

[0096] Atorvastatin 10g

[0097] HPMC 6cp 6g

[0099] Isolation film coat layer:

[0100] Opadry II

[0101] Make 1000 tablets by the following preparation method: (1) Tablet core preparation Get sodium chloride and pulverize, cross 100 mesh sieves, mix with acipimox evenly, take 70% ethanol solution containing 8% PVPk30 as wetting agent, prepare Soft material, passed through a 20-mesh sieve to granulate, dried at 45°C for 2 hours, granulated, added with magnesium stearate, mixed evenly, compressed into tablets, and compressed into 1000 tablets by conventional tableting technology. (2) Tablet core coating: take cellulose acetate, add 280ml of acetone, st...

Embodiment 2

[0104] Chip composition:

[0105] Acipimus 150g

[0106] Fructose 45g

[0107] Lactose 40g

[0108] PVPk30 4g

[0110] Coating film composition:

[0111] Cellulose acetate 8g

[0112] Macrogol 4000 2g

[0113] Dibutyl sebacate 1.5g

[0114] Immediate release drug layer composition:

[0115] Atorvastatin 10g

[0116] HPMC 6cp 6g

[0117] Sodium Lauryl Sulfate 2g

[0118] Titanium dioxide 1g

[0120] Make 1000 tablets by the following preparation method: (1) Tablet core preparation Get sodium chloride and pulverize, cross 100 mesh sieves, mix with acipimox evenly, take 70% ethanol solution containing 8% PVPk30 as wetting agent, prepare Soft material, passed through a 20-mesh sieve to granulate, dried at 45°C for 2 hours, granulated, added with magnesium stearate, mixed evenly, compressed into tablets, and compressed into 1000 tablets by conventional tableting technology. (2) Tablet core coating: take cellulos...

Embodiment 3

[0123] Chip composition:

[0124] Acipimus 200g

[0125] NaCl 90g

[0126] PVPk30 4.8g

[0128] Coating film composition:

[0129] Ethyl cellulose 10g

[0130] HPMC6cp 3g

[0131] Macrogol 4000 1g

[0132] Immediate release drug layer composition:

[0133] Atorvastatin 10g

[0134] HPMC 6cp 6g

[0136] Isolation film coat layer:

[0137] Opadry II

[0138] Make 1000 tablets by the following preparation method: (1) tablet core preparation Get sodium chloride and pulverize, cross 100 mesh sieves, mix with acipimox evenly, take the 50% ethanol solution containing 5% HPMC6cp as wetting agent, prepare Soft material, passed through a 20-mesh sieve to granulate, dried at 5°C for 2 hours, granulated, added with magnesium stearate, mixed evenly, compressed into tablets, and compressed into 1000 tablets by conventional tableting technology. (2) Core coating: take ethyl cellulose, add 320ml of ethanol, stir to dissolve; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com