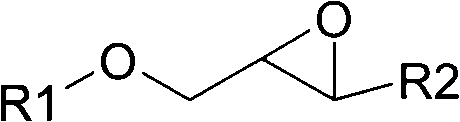

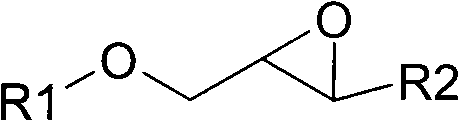

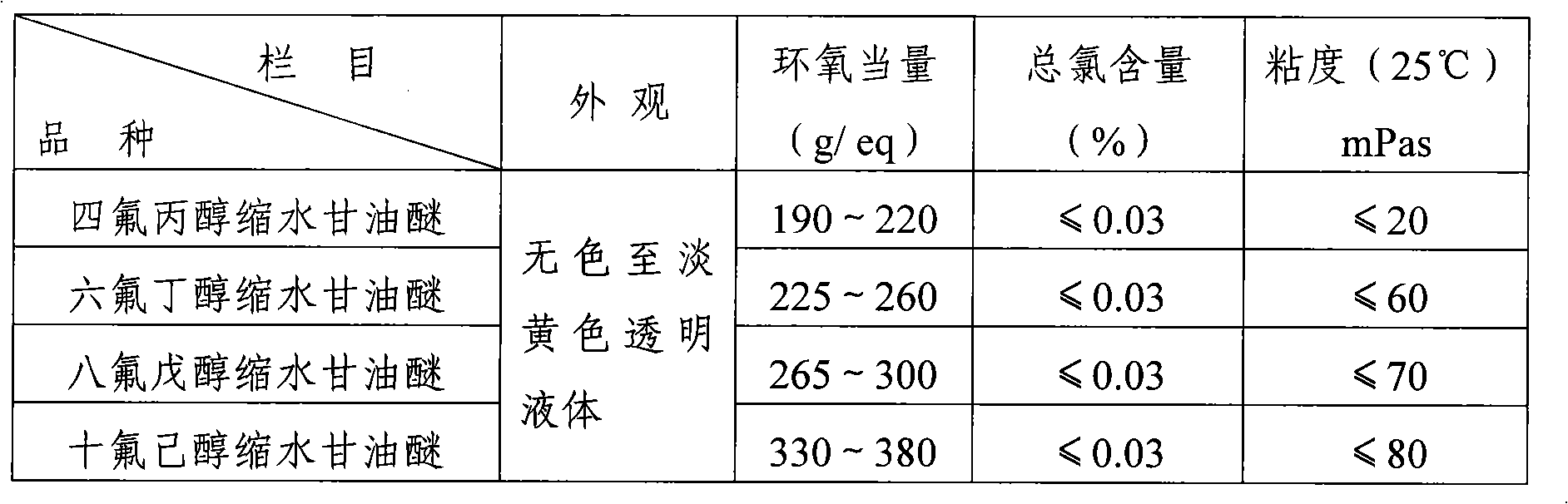

Fluorine-containing epoxide resin reactive diluent and preparation thereof

An epoxy resin reactive diluent and fluorine-containing alcohol technology, applied in the diluent field, can solve the problems of excessive epichlorohydrin recovery process, incomplete penetration, poor flame retardancy, etc., improve comprehensive performance, and facilitate closed-loop , the effect of improving characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] In a 5000ml three-necked flask equipped with an oil bath heating device, a stirrer, a thermometer, and a condenser, add 3000g of tetrafluoropropanol, start stirring, raise the temperature of the oil bath to 110°C, collect the transparent fraction above 100°C, and seal it for future use .

[0047] In a 2000ml four-neck flask equipped with a water bath heating device, a stirrer, a thermometer, a condenser, and a balance funnel, add 200g of tetrafluoropropanol and 2g of boron trifluoride ether. The temperature of the system was controlled at 60° C., and 200 g of 1-chloro-2,3-propylene oxide was added dropwise through a balance funnel for etherification reaction, and the reaction time was 4 hours. During the dropping process, constantly observe the temperature change of the system, and take appropriate cooling measures. Add 85g of flake NaOH in portions through the feeding port, and the separation time is 20 minutes. The reaction time is 6h, and the temperature is 30°C. ...

Embodiment 2

[0050] In a 5000ml three-necked flask equipped with an oil bath heating device, a stirrer, a thermometer, and a condenser, add 3000g of tetrafluoropropanol, start stirring, raise the temperature of the oil bath to 110°C, collect the transparent fraction above 100°C, and seal it for future use .

[0051] In a 2000ml four-necked flask equipped with a water bath heating device, a stirrer, a thermometer, a condenser, and a balance funnel, add 200g of tetrafluoropropanol and boron trifluoride ether SnCl 4 2g. The temperature of the system was controlled at 100° C., and 225 g of 1-chloro-2,3-propylene oxide was added dropwise through a balance funnel for etherification reaction, and the reaction time was 2 hours. During the dropping process, constantly observe the temperature change of the system, and take appropriate cooling measures. Then add 85 g of flaky KOH in portions through the feeding port, with an interval of 20 minutes. The reaction time is 2h, and the temperature is 2...

Embodiment 3

[0054] In a 5000ml three-necked flask equipped with an oil bath heating device, a stirrer, a thermometer, and a condenser, add 3000g of tetrafluoropropanol, start stirring, raise the temperature of the oil bath to 110°C, collect the transparent fraction above 100°C, and seal it for future use .

[0055] In a 2000ml four-neck flask equipped with a water bath heating device, a stirrer, a thermometer, a condenser, and a balance funnel, add 200g of tetrafluoropropanol and 1g of boron trifluoride ether. The temperature of the system was controlled at 30° C., and 200 g of 1-chloro-2,3-propylene oxide was added dropwise through a balance funnel for etherification reaction, and the reaction time was 8 hours. During the dropping process, constantly observe the temperature change of the system, and take appropriate cooling measures. Then add 100 g of flaky NaOH in portions through the feeding port, with an interval of 20 minutes. The reaction time is 2h, and the temperature is 50°C. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com