Two-component water paint for railroad car coating

A railway vehicle, two-component technology, used in epoxy resin coatings, coatings, latex paints, etc., can solve the problems of air, water pollution, human health, harmful waste gas, waste water discharge, etc., to save energy, Excellent water resistance and solvent resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] (1) Two-component water-based epoxy primer consists of the following parts: 15 kg of deionized water, 12 kg of water-based epoxy resin, 9 kg of titanium dioxide, 0.05 kg of carbon black, 0.95 kg of iron oxide yellow , 0.04 kg of silicone defoamer, 14 kg of talc, 11 kg of complex zinc phosphate, 2.2 kg of zinc oxide, 2.8 kg of precipitated barium sulfate, 0.46 kg of water-based epoxy accelerator.

[0069] Produced by the aforementioned production process.

[0070] Application example: Take 67.5 kg of the above-mentioned coating and mix it with 28 kg of water-based epoxy resin curing agent, stir evenly, make boards and perform coating film performance testing according to the relevant national standards of the People's Republic of China.

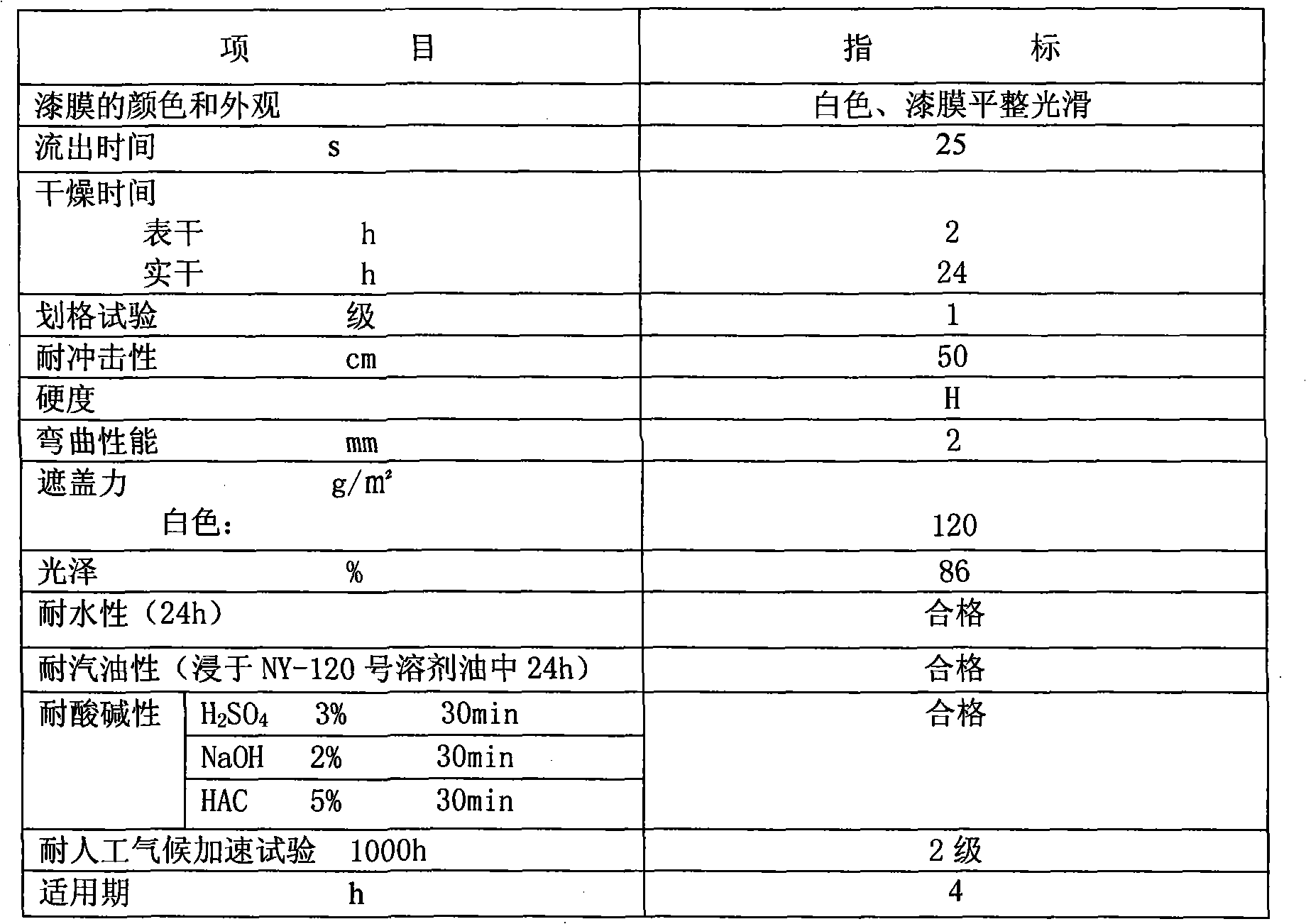

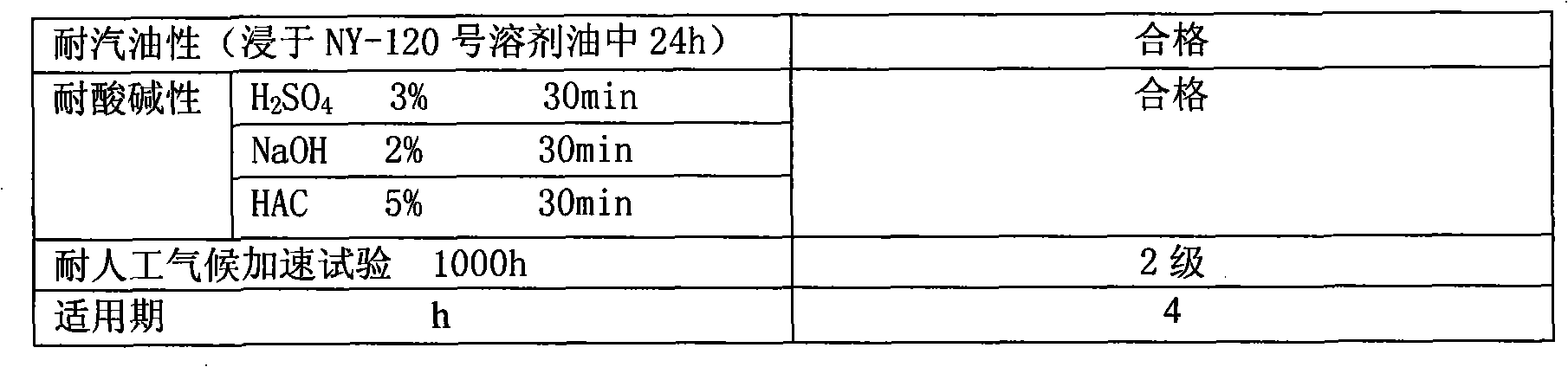

[0071] The result is as follows:

[0072] project name

technical indicators

Paint film color and appearance

Grey, flat and smooth paint film

Non-volatile content %

70

Outflow time s

40 ...

Embodiment 2

[0081] (1) Two-component water-based epoxy primer consists of the following parts: 17.85 kg of deionized water, 12.5 kg of water-based epoxy resin, 10.3 kg of titanium dioxide, 0.06 kg of carbon black, 1.0 kg of iron oxide yellow , 0.045 kg of silicone defoamer, 14.3 kg of talc, 11.2 kg of complex zinc phosphate, 2.455 kg of zinc oxide, 3.6 kg of precipitated barium sulfate, 0.58 kg of water-based epoxy accelerator.

[0082] Produced by the aforementioned production process.

Embodiment 3

[0093] (1) Two-component water-based epoxy primer consists of the following parts: 20 kg of deionized water, 15 kg of water-based epoxy resin, 10.5 kg of titanium dioxide, 0.08 kg of carbon black, 1.42 kg of iron oxide yellow , 0.05 kg of silicone defoamer, 18 kg of talc, 15 kg of complex zinc phosphate, 3 kg of zinc oxide, 4 kg of precipitated barium sulfate, 0.95 kg of water-based epoxy accelerator.

[0094] Produced by the aforementioned production process.

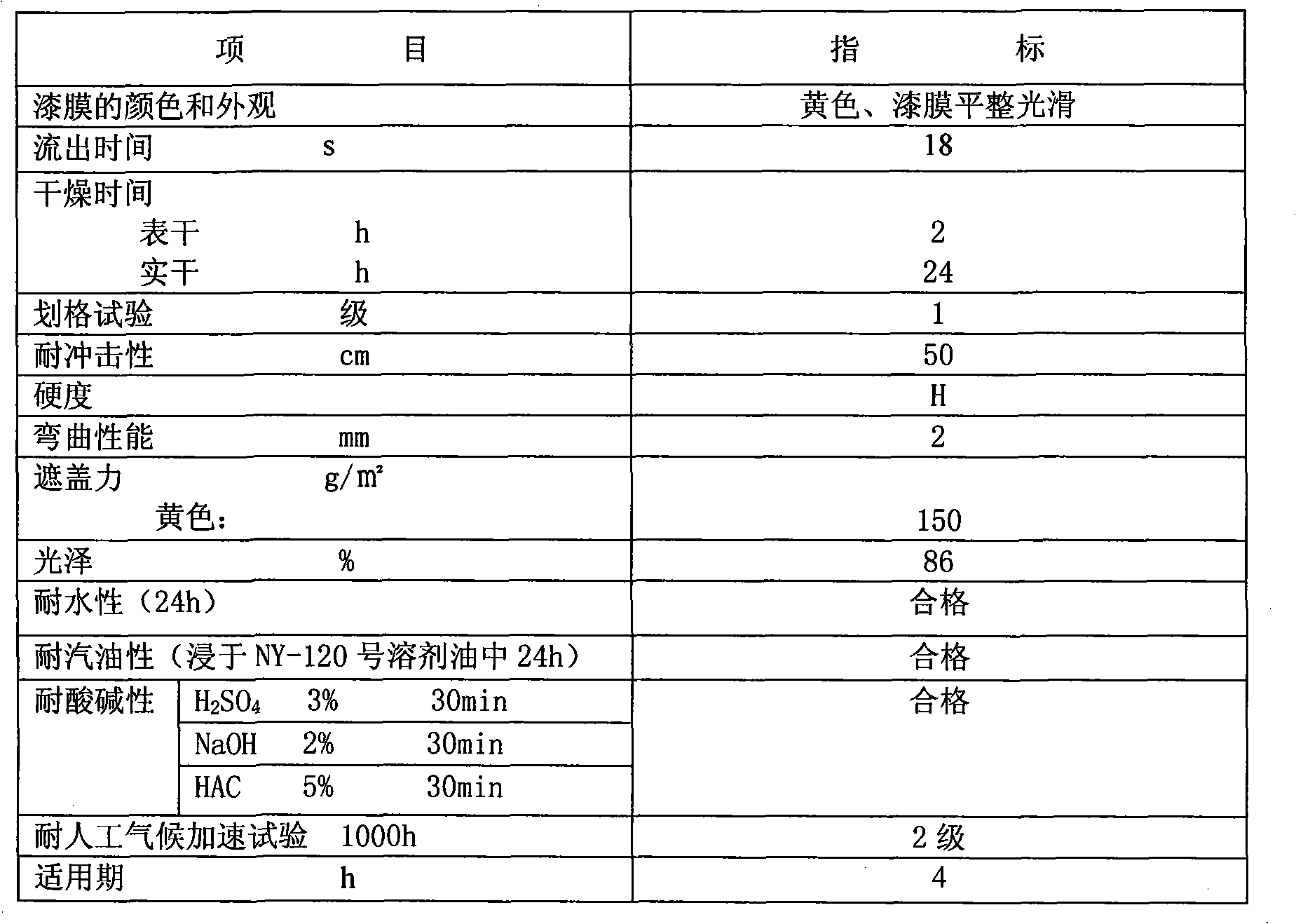

[0095] Application example: take 88 kilograms of the above-mentioned coatings and mix 35 kilograms of water-based epoxy resin curing agent, stir evenly, make boards according to the relevant national standards of the People's Republic of China and conduct coating film performance testing, the results are as follows:

[0096] project name

technical indicators

Paint film color and appearance

Grey, smooth paint film, no abnormal defects

Non-volatile content %

69

Outflow time s ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com