Novel microwave oscillator driven by spinning current

A microwave oscillator, spin current technology, applied in resonators, waveguide devices, circuits, etc., can solve the problems of large injection current and external magnetic field, low microwave emission efficiency, low microwave transmission power, etc., and achieve high microwave power. Output, no external magnetic field, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

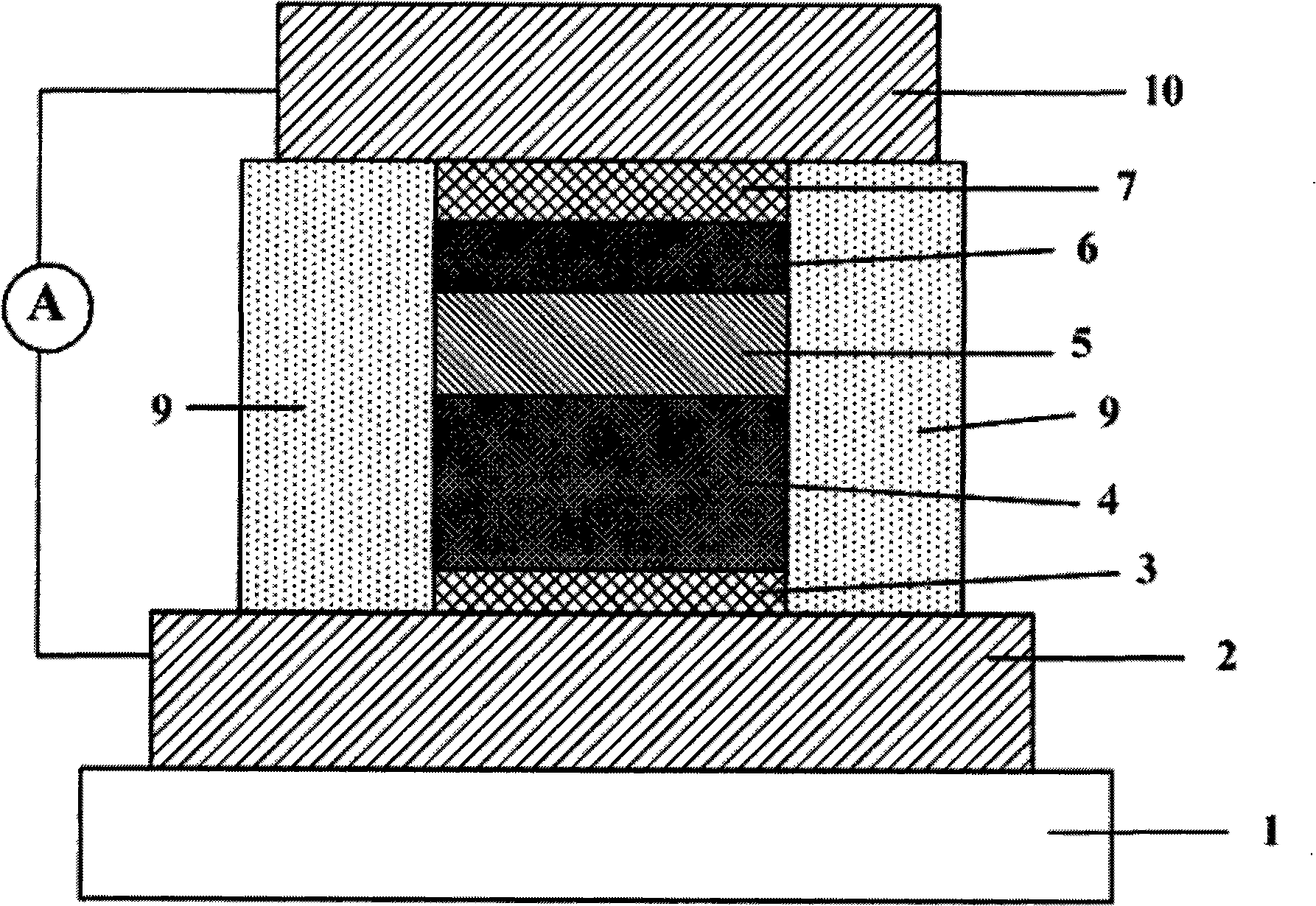

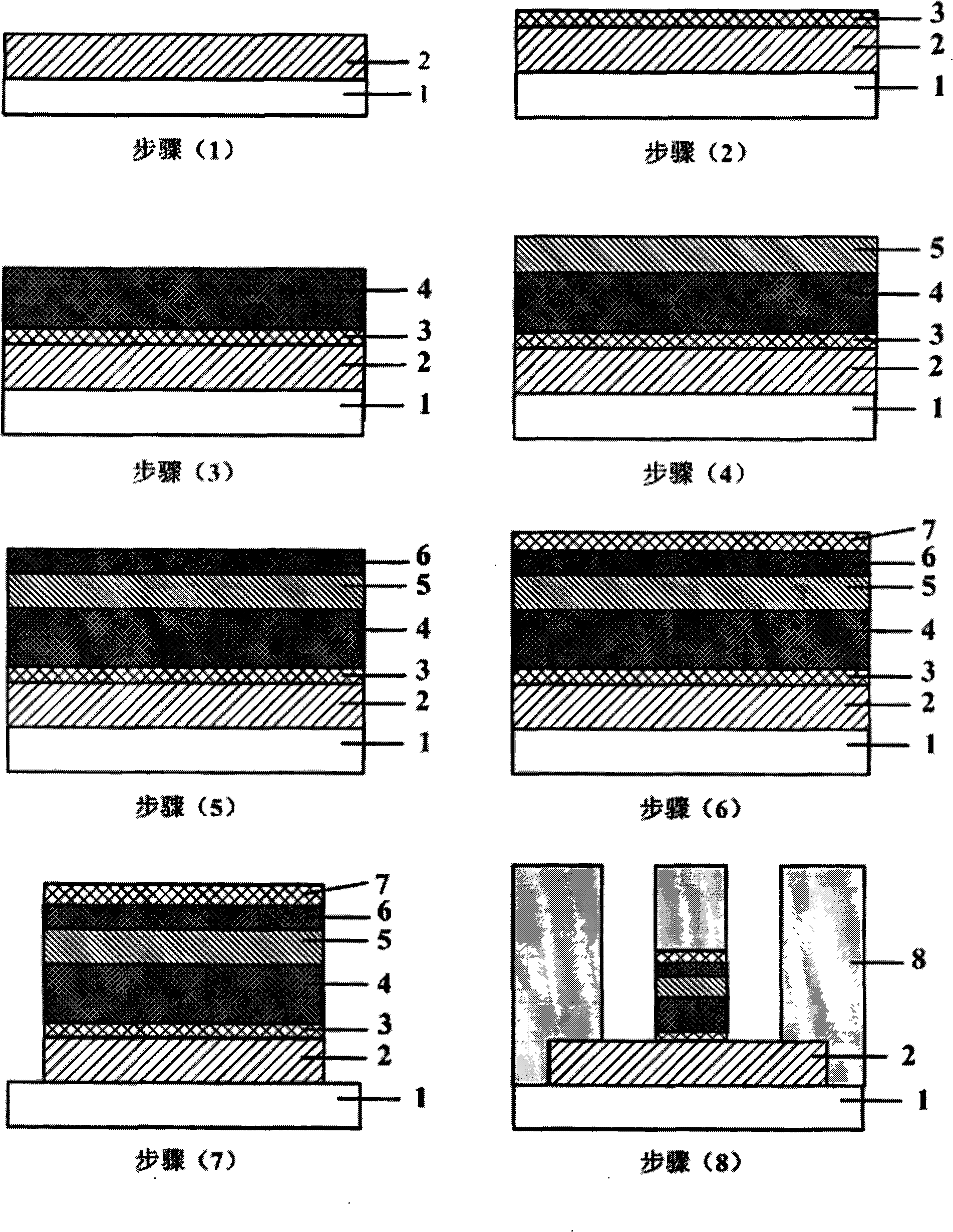

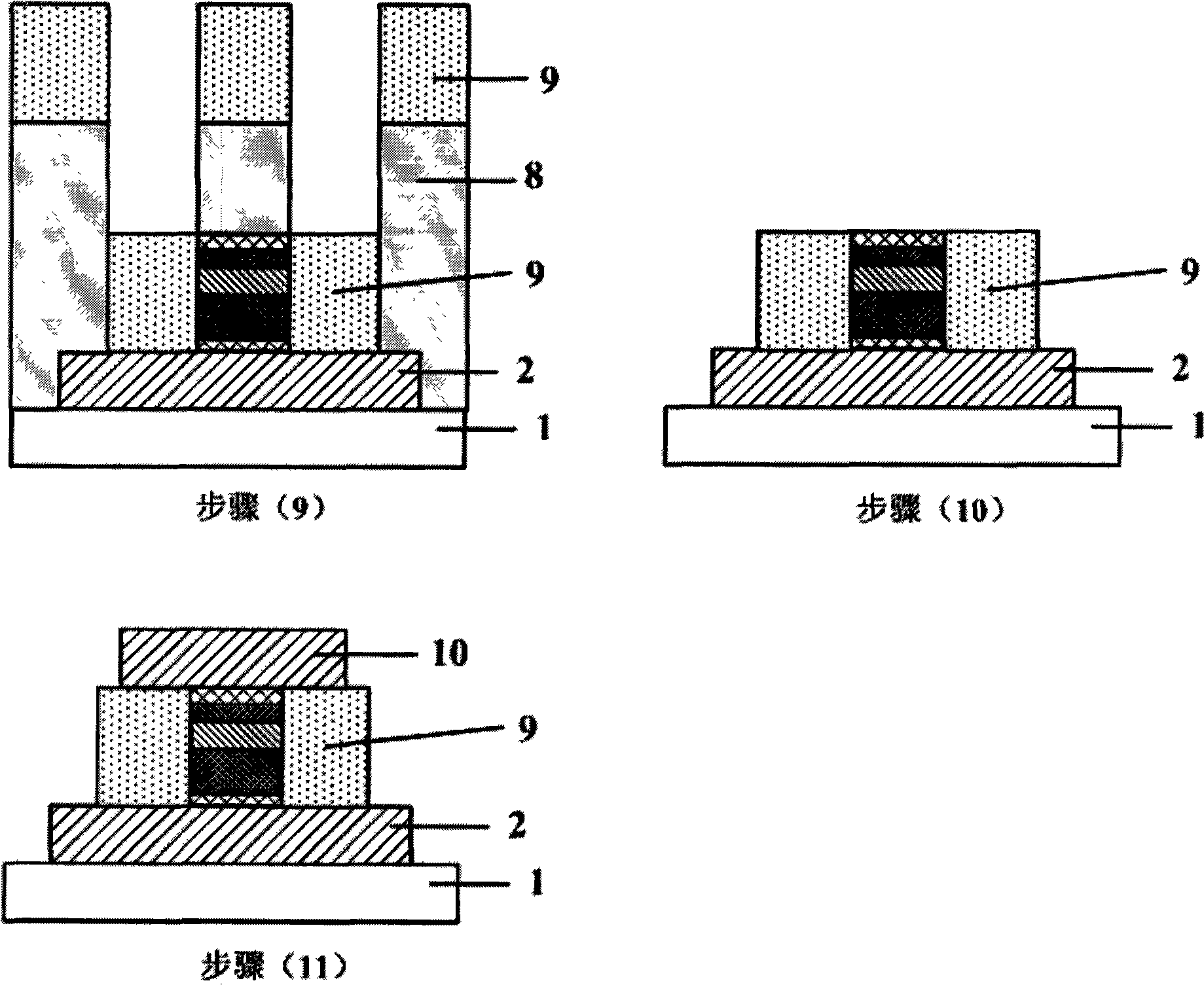

[0030] figure 2 It is a process flow diagram of the preparation method of the present invention. The structure is to first deposit the bottom electrode layer 2 on the silicon oxide substrate 1; then use the CMS-A six-target magnetron sputtering system of the American LESKER company to grow in sequence: the seed layer 3, the fixed layer 4, the isolation layer 5, The free layer 6 and the protective layer 7, wherein during the growth process of the fixed layer 4 and the free layer 6, the components of the magnetron sputtering equipment are used to apply an induced magnetic field, and the direction of the induced magnetic field is in the film plane and perpendicular to each other; and etching process to produce the bottom electrode pattern, and then use electron beam exposure and Ar ion beam etching to process the multilayer film structure on the bottom electrode 2 into a columnar structure with a lateral size of 100 ± 50 nanometers, and retain the photoresist 8; The insulating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com