Formaldehyde exhaust-gas efficient film absorption technique

A high-efficiency membrane, formaldehyde technology, applied in the separation of dispersed particles, chemical instruments and methods, separation methods, etc., can solve the problems of low efficiency, high cost, long processing period, etc., and achieve high processing efficiency, short processing period, and operating conditions. mild effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

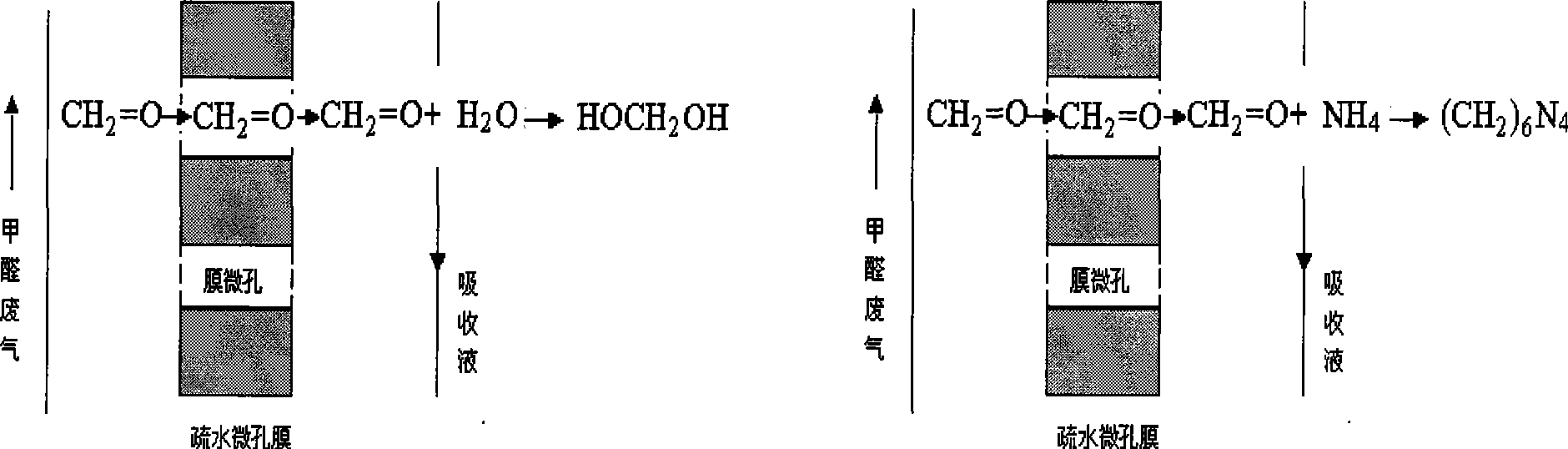

Method used

Image

Examples

Embodiment 1

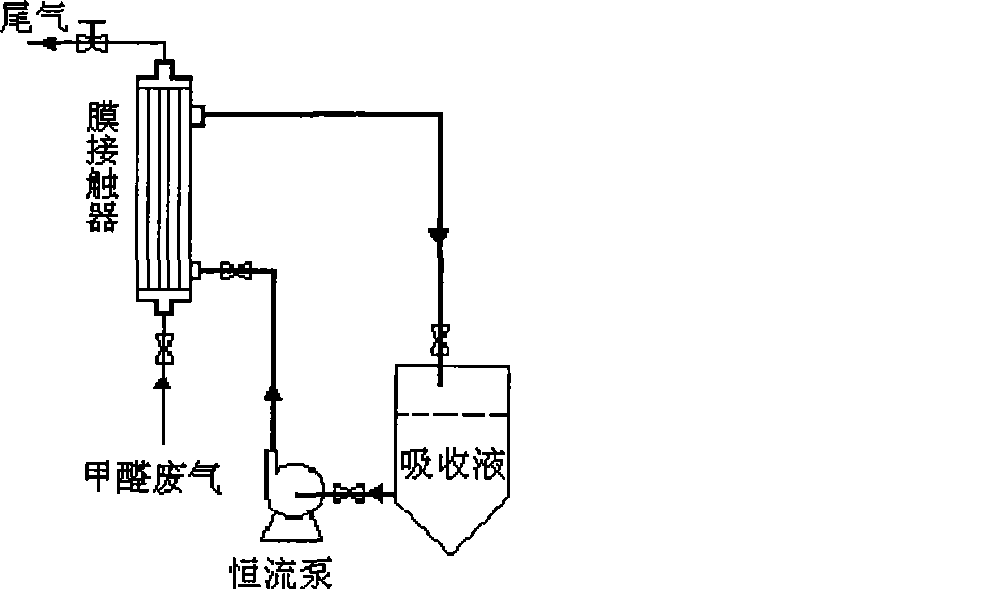

[0022] according to figure 2 The processing device in this paper adopts a polypropylene membrane contactor with a diameter-to-height ratio of 0.15, a packing density of 0.27, and a membrane pore diameter of 0.2 μm. Formaldehyde waste gas (inlet concentration 5mg / L, flow rate 100mL / min) is treated with absorption liquid (water, flow rate 200mL / min), the concentration of formaldehyde in the outlet tail gas is 0mg / L, and the removal rate is 100%.

Embodiment 2

[0024] according to figure 2 The processing device, formaldehyde waste gas (inlet concentration is 458mg / L, flow rate is 100mL / min) is treated with absorption liquid (water, flow rate is 200mL / min), the concentration of formaldehyde in the outlet tail gas is 0mg / L, and the removal rate is 100% .

Embodiment 3

[0026] according to figure 2 The processing device, the formaldehyde exhaust gas (inlet concentration is 462mg / L, flow rate is 100mL / min) is treated by the absorption liquid (2% ammonia water, flow rate is 200mL / min), the formaldehyde concentration in the outlet tail gas is 0mg / L, the removal rate is 100%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com