High stability polymer-based nano catalyst and preparation method and use thereof

A nano-gold and polymer technology, applied in the field of chemistry, can solve problems such as the lack of research reports on gold nanoparticles, and achieve the effects of simple synthesis, high stability, and high product reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

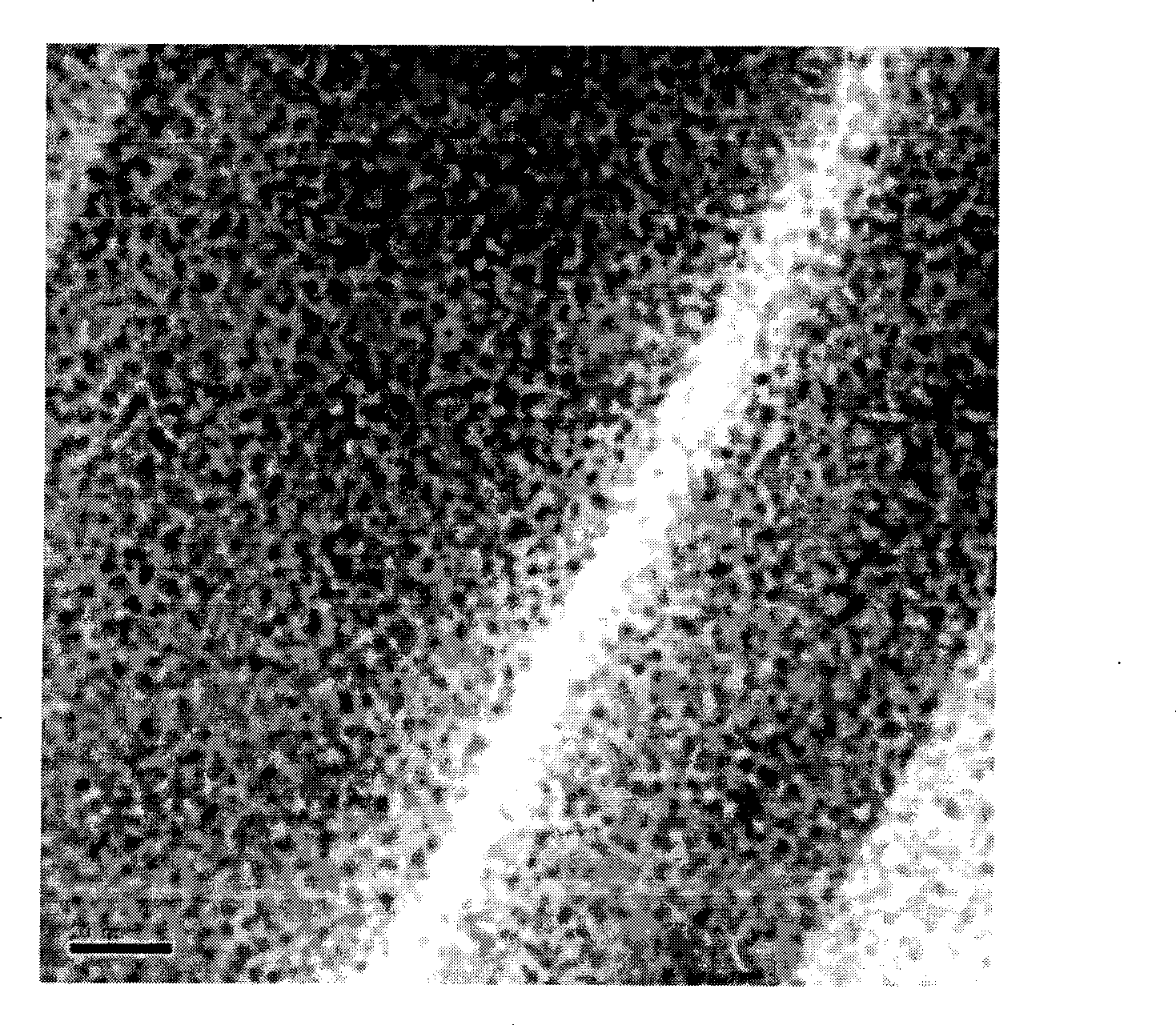

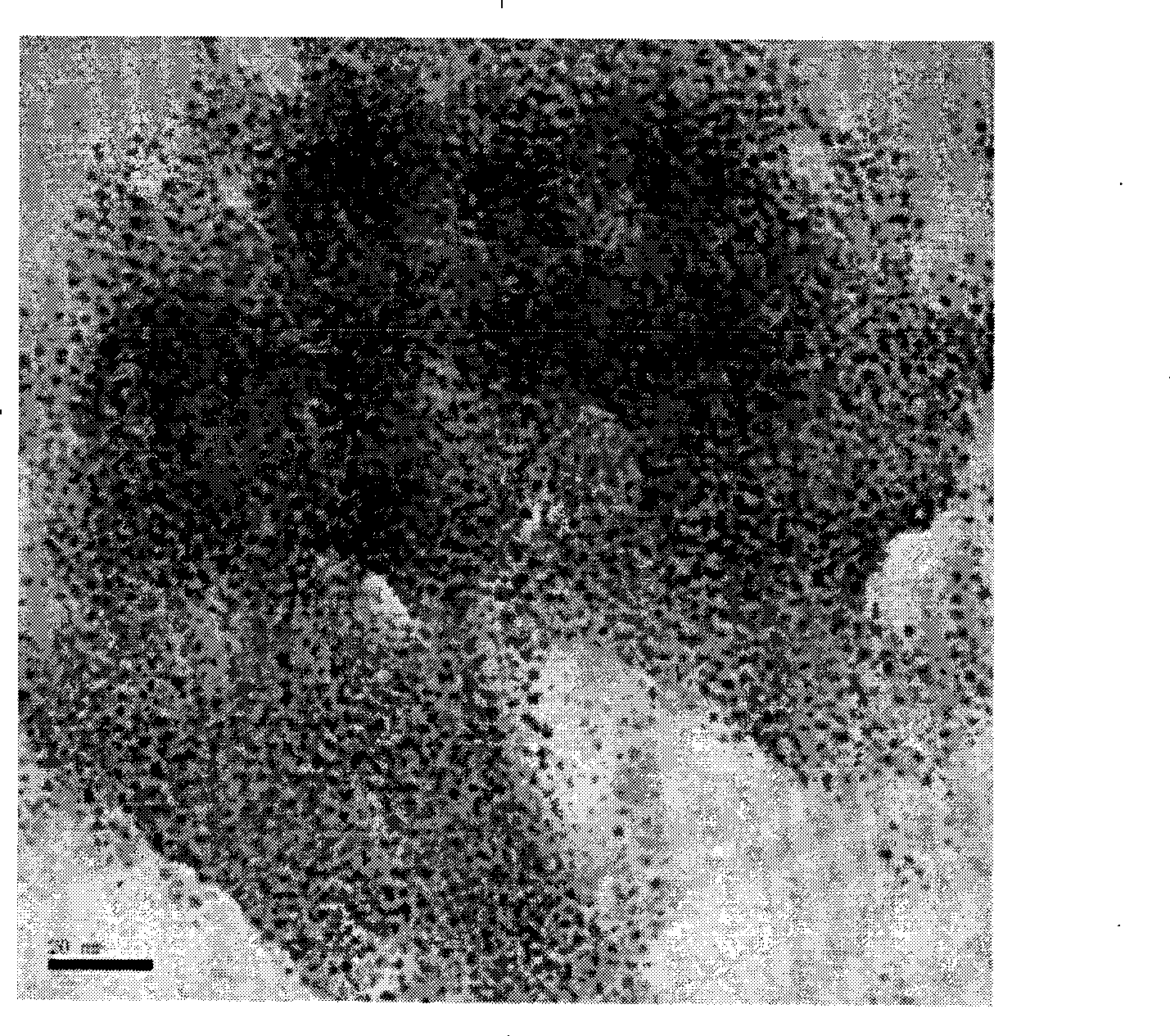

Image

Examples

Embodiment 1

[0035] Preparation of polymer-based nano-gold catalyst

[0036] (1) Raw material preparation: o-aminothiophenol was distilled under reduced pressure before use, and stored in a refrigerator at 4°C for later use. Chlorauric acid is prepared into a 0.1mol / L aqueous solution with deionized water before use. Other chemical reagents were of analytical grade, and water was deionized water.

[0037] (2) Synthesis and preparation: 0.05g of o-aminothiophenol is dissolved in 18.0ml, 1.0mol / L of HCl aqueous solution, fully mixed to obtain a homogeneous solution, and then 2.0ml of chloroauric acid is added to the system at one time Aqueous solution, keep the concentration of o-aminothiophenol in the reaction system at 0.02mol / L, the molar ratio of o-aminothiophenol to chloroauric acid is 2:1, stir fully for half a minute to make the reaction system evenly mixed, at 0-30℃ React within the temperature range for 12 hours.

[0038] (3) Post-treatment of the product: Centrifuge the reaction...

Embodiment 2

[0040] Preparation of polymer-based nano-gold catalyst

[0041] (1) Raw material preparation: o-aminothiophenol was distilled under reduced pressure before use, and stored in a refrigerator at 4°C for later use. Chlorauric acid is prepared into a 0.1mol / L aqueous solution with deionized water before use. Other chemical reagents were of analytical grade, and water was deionized water.

[0042] (2) Synthesis and preparation: 0.10g of o-aminothiophenol is dissolved in 16.0ml, 1.0mol / L of HCl aqueous solution, fully mixed to obtain a homogeneous solution, and then 4.0ml of chloroauric acid is added to the system at one time Aqueous solution, keep the concentration of o-aminothiophenol in the reaction system at 0.04mol / L, the molar ratio of o-aminothiophenol to chloroauric acid is 2:1, stir fully for half a minute to make the reaction system evenly mixed, at 0-30℃ React within the temperature range for 12 hours.

[0043] (3) Post-treatment of the product: Centrifuge the reaction...

Embodiment 3

[0045] Preparation of polymer-based nano-gold catalyst

[0046] (1) Preparation of raw materials: o-aminothiophenol was distilled under reduced pressure before use, and stored in a refrigerator at 4°C for later use. Chlorauric acid is prepared into a 0.1mol / L aqueous solution with deionized water before use. Other chemical reagents were of analytical grade, and water was deionized water.

[0047](2) Synthetic preparation: 0.20g of o-aminothiophenol is dissolved in 12.0ml, 1.0mol / L of HCl aqueous solution, fully mixed to obtain a homogeneous solution, and then 8.0ml of chloroauric acid is added to the system at one time Aqueous solution, keep the concentration of o-aminothiophenol in the reaction system at 0.08mol / L, the molar ratio of o-aminothiophenol to chloroauric acid is 2:1, stir fully for half a minute to make the reaction system evenly mixed, at 0-30℃ React within the temperature range for 12 hours.

[0048] (3) Post-treatment of the product: Centrifuge the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com