Preparation method for Cu(I)-Y molecular sieve adsorption desulphurizing agent

A technology of adsorption desulfurization and molecular sieve, which is applied in the field of Cu-Y molecular sieve preparation, can solve the problems of long exchange time and achieve the effects of simple process, high copper content and strong adsorption and desulfurization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] When using the NaY molecular sieve synthesized in situ on the magnetic substrate to synthesize the Cu(I)-Y molecular sieve adsorbent, a preferred preparation method comprises the following steps:

[0015] A Synthesis of Magnetic NaY Molecular Sieves

[0016] First, prepare the directing agent: mix water glass and high alkali sodium metaaluminate solution, stir evenly, and age at room temperature to 100° C. for 12 to 36 hours, preferably at 40 to 50° C. and for 24 to 30 hours. Then, the directing agent, the water glass and the low-alkali sodium metaaluminate solution are mixed, and the aluminum sulfate solution and the deionized water are sequentially added under stirring to obtain a synthetic gel. Then, add fine particles of the magnetic matrix (preferably 100-500 mesh) into the synthetic gel, stir evenly, and then crystallize at 80-120°C for 20-60h, preferably at a crystallization temperature of 95-105°C. The time is 48-56 hours. The crystallization process is prefer...

Embodiment 1~6

[0026] This example illustrates the preparation of the Cu(I)-Y molecular sieve adsorbent of the present invention.

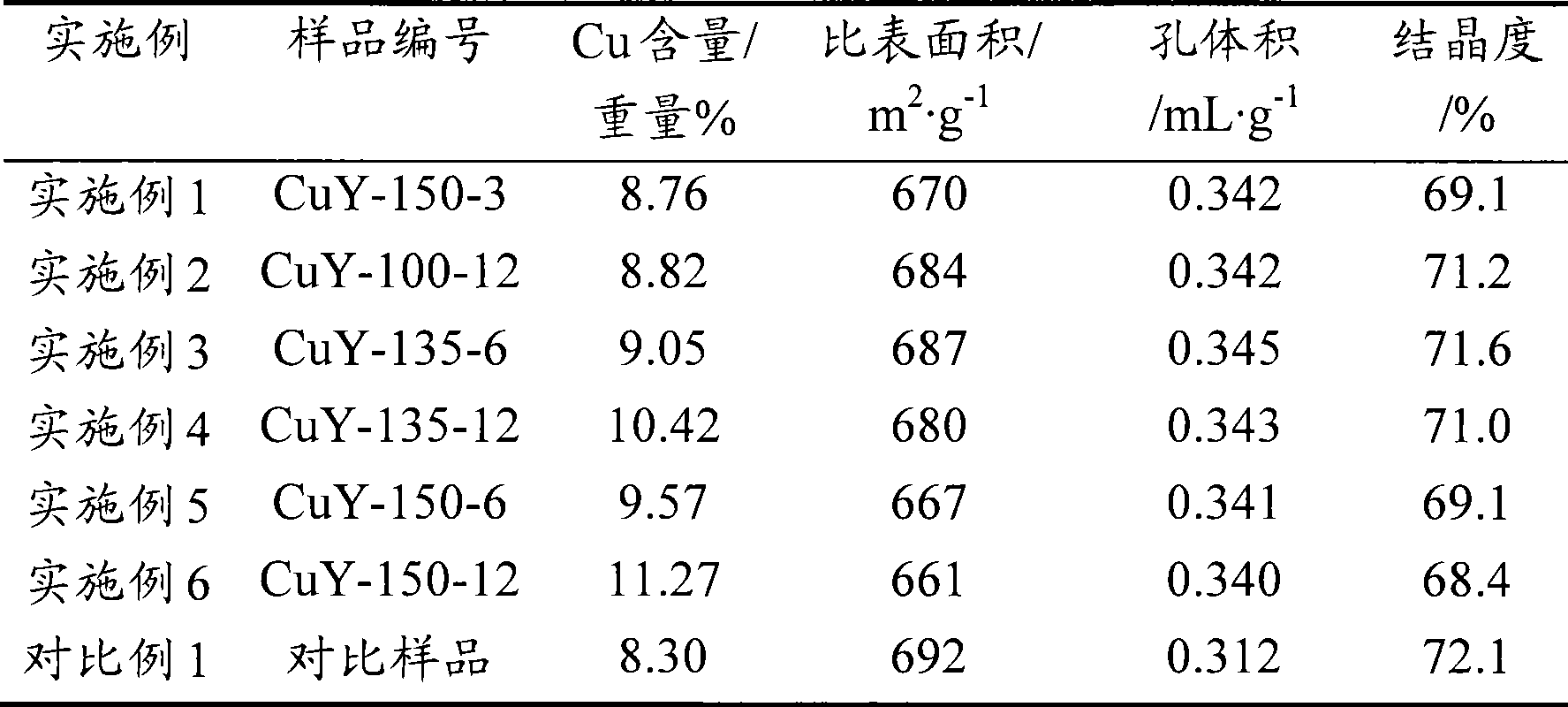

[0027] NaY molecular sieve (Si / Al molar ratio is 2.31, produced by Catalyst Factory of Changling Branch of Sinopec Corporation) and Cu(NO 3 ) 2 (Analytical grade, Beijing Yili Fine Chemicals Co., Ltd.) solution (concentration: 0.5mol / L) was mixed at a solid-liquid ratio of 0.05:1, and ion exchange was carried out at 100°C, 135°C or 150°C, and the exchange time was 3h, 6h or 12h, then wash with deionized water until neutral, dry in air at 100°C for 18h, and then dry in 500°C N 2 Roasting in medium for 3h, and continue in N 2 Cool to room temperature in the atmosphere and store in airtight. The exchange equipment used is a pressure-resistant closed exchange tank, and the stirring equipment is a self-made rotary oven with controllable temperature and rotation speed, and the rotation speed is 30 rpm.

[0028] The operating conditions and physical and chemical pr...

Embodiment 7~12

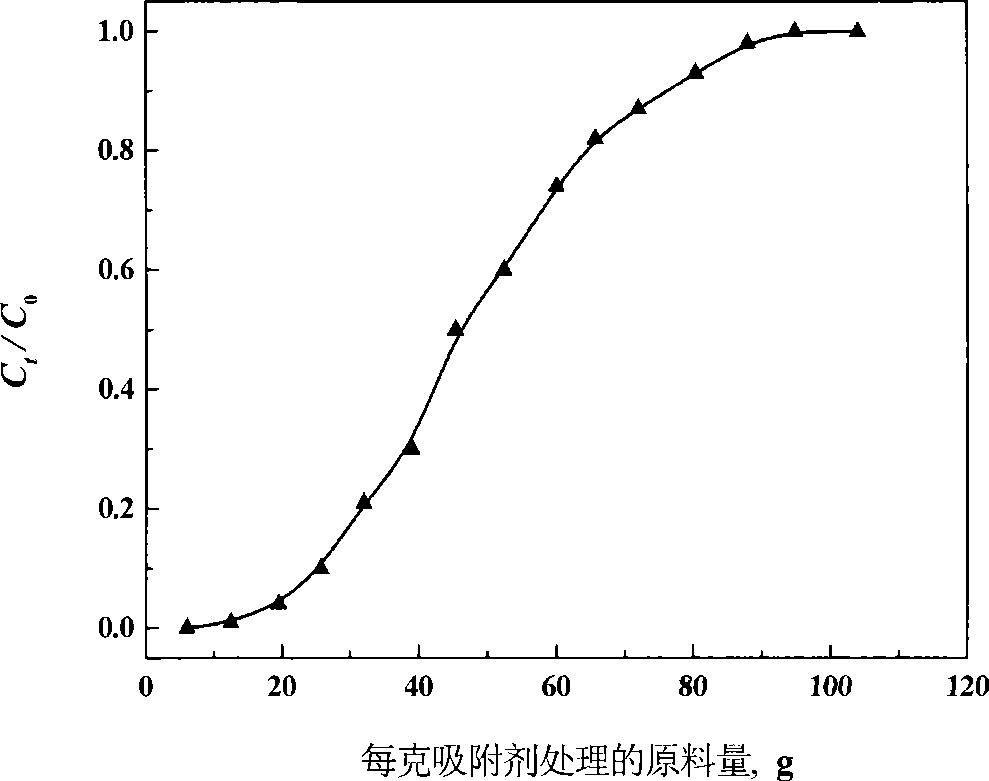

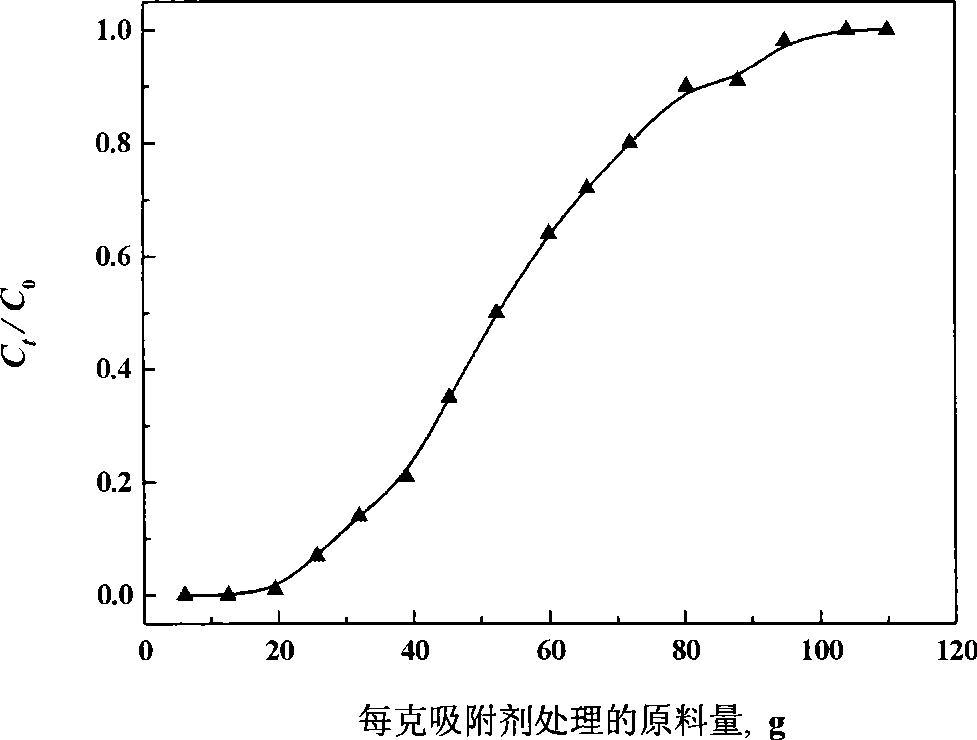

[0034] This example illustrates the gasoline adsorption desulfurization performance of the Cu(I)-Y molecular sieve adsorbent prepared in the present invention. The sulfur content in the oil was determined by gas chromatography-atomic emission spectrometry (GC-AED).

[0035] The Cu(I)-Y molecular sieve adsorbent prepared in Examples 1-6 is adopted to investigate the effect of model gasoline (n-octane, total sulfur content is 1012 μg·mL) by batch method. -1 , the composition of sulfur-containing compounds is shown in Table 2), and the desulfurization performance was adsorption and desulfurization for 1.0 h at room temperature, normal pressure, and the operating conditions of an agent-oil weight ratio of 1:50. By measuring the sulfur content of gasoline before and after desulfurization, the desulfurization rate of the adsorbent was calculated, and the results are shown in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com