Synthesis of monomethoxy polyglycol

A technology of polyethylene glycol and monomethoxyl, which is applied in the field of synthesizing monomethoxypolyethylene glycol, can solve the problems of polyethylene glycol separation difficulties, decreased reaction selectivity, catalyst deactivation, etc., and achieve the molecular weight of the product The effect of narrow distribution, high purity of reaction products and high reaction selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

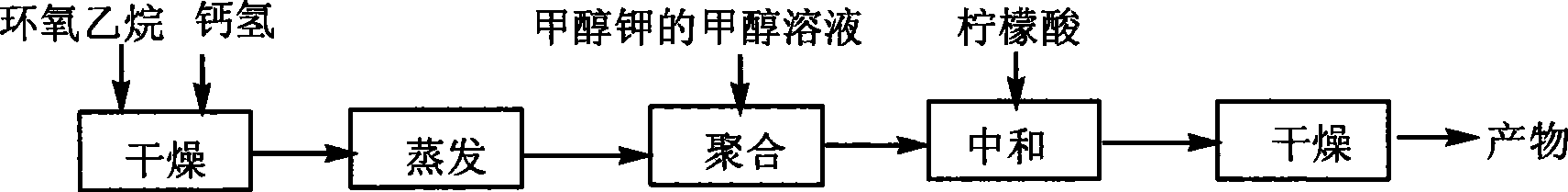

[0023] Such as figure 1 As shown, 1.20kg of ethylene oxide (moisture content is 200ppm) is added to a 10-liter evaporator through a drier equipped with 50g of calcium hydrogen (a total of 125kg of ethylene oxide can be processed), and a condenser and a condenser are connected after the evaporator. A receiving tank. During the heating and evaporation process, the steam is condensed by the condenser and then collected into the receiving tank. The ethylene oxide was then transferred to a dry ethylene oxide tank to obtain 1.10 kg of ethylene oxide with a moisture content of 10 ppm and a yield of 91.67%.

[0024] 0.5 liter of anhydrous toluene (moisture content: 4.8 ppm) was added to a 5 liter autoclave. The kettle has a solid feeding pipeline, an ethylene oxide feeding pipeline with a distributor, a stirrer, a thermometer and a explosion-proof membrane (8Kg / cm 2 ) and explosion-proof piping for pressure gauges. Anhydrous toluene was heated to 90°C. Stir for 30 minutes (the sp...

Embodiment 2

[0031] Put 1.30kg of ethylene oxide (moisture content is 200ppm) into a 10-liter evaporating kettle through a drier equipped with 50g of calcium hydrogen (a total of 125kg of ethylene oxide can be processed), and a condenser and a receiving tank are connected behind the evaporating kettle . Heating and evaporating, the steam is condensed by the condenser and then collected into the receiving tank. Ethylene oxide is transferred to dry ethylene oxide tank again, and 1.20kg oxirane is received. The moisture content is 9ppm, and the yield is 92.31%.

[0032] 0.5 liter of anhydrous toluene (moisture content: 4.8 ppm) was added to a 5 liter autoclave. The kettle has a solid feeding pipeline, an ethylene oxide feeding pipeline with a distributor, a stirrer, a thermometer and a explosion-proof membrane (8Kg / cm 2) and explosion-proof piping for pressure gauges. Anhydrous toluene was heated to 90°C. Stir for 30 minutes (the speed of the mixer is 500 rpm), and ensure that the two fe...

Embodiment 3

[0038] Add 1.25kg of ethylene oxide and 0.5g of calcium hydrogen into a 10-liter evaporator with agitator, and connect a condenser and a receiving tank behind the evaporator. After half an hour of vigorous stirring (the speed of the stirrer is 500 rpm), keep stirring and heat to evaporate, and the steam is condensed by the condenser and then collected into the receiving tank. The ethylene oxide was then transferred to a dry ethylene oxide tank to obtain 1.10 kg of ethylene oxide with a water content of 7 ppm and a yield of 88%.

[0039] Add 0.5 liter of anhydrous diethylene glycol dimethyl ether (moisture content: 5 ppm) to a 5 liter autoclave. The kettle has a solid feeding pipeline, an ethylene oxide feeding pipeline with a distributor, a stirrer, a thermometer and a explosion-proof film (8Kg / cm 2 ) and explosion-proof piping for pressure gauges. Anhydrous diglyme was heated to 90°C. Stir for 30 minutes (the speed of the mixer is 500 rpm), and ensure that the two feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com