Multicomponent doping spherical lithium iron phosphate anode material and method of manufacturing the same

A lithium iron phosphate and cathode material technology, applied in chemical instruments and methods, phosphorus compounds, electrical components, etc., can solve the problems of unifying conductivity and filling density of difficult materials, poor comprehensiveness, etc., and reduce reaction activation. energy, simple process, and the effect of improving processing behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

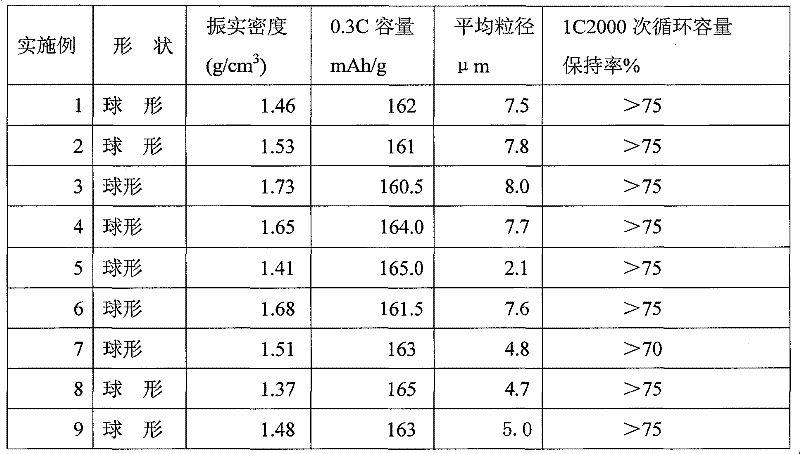

Examples

Embodiment 1

[0022] 1) Put 41g lithium fluoride, 58g lithium carbonate, 118g ferrous fluoride, 255g ferrous oxalate, 370g ammonium dihydrogen phosphate, 3.9g magnesium fluoride, 11g titanium fluoride, 100g sucrose and 780g deionized water in a ball mill Medium mixing for 5 hours;

[0023] 2) drying and ball milling for 3 hours;

[0024] 3) After heating up to 350°C at a rate of 2°C / min in a nitrogen protection furnace, keep the temperature constant for 6 hours;

[0025] 4) cooling to room temperature, ball milling in ball mill for 8 hours;

[0026] 5) At 1500KN / cm 2 Tablets under pressure;

[0027] 6) In the nitrogen protection furnace, the temperature was raised to 760°C at a rate of 3°C / min, and the temperature was kept constant for 12 hours;

[0028] 7) Cool naturally, and ball mill for 3 hours to obtain the multi-component doped spherical lithium iron phosphate positive electrode material of the present invention, and the product is spherical. The average particle size of the prod...

Embodiment 2

[0031] 1) 83g of lithium fluoride, 544g of ferrous oxalate, 370g of ammonium dihydrogen phosphate, 4g of magnesium fluoride, 14.86g of titanium fluoride, 200g of sucrose and 607.93g of deionized water were placed in a ball mill and mixed for 5 hours;

[0032] 2) drying and ball milling for 3 hours;

[0033] 3) After heating up to 350°C at a rate of 2°C / min in a nitrogen protection furnace, keep the temperature constant for 6 hours;

[0034] 4) cooling to room temperature, ball milling in ball mill for 8 hours;

[0035] 5) At 1500KN / cm 2 Tablets under pressure;

[0036] 6) In the nitrogen protection furnace, the temperature was raised to 760°C at a rate of 3°C / min, and the temperature was kept constant for 12 hours;

[0037] 7) Cool naturally, and ball mill for 3 hours to obtain the multi-component doped spherical lithium iron phosphate cathode material of the present invention, which is a spherical powder. The measured average particle size of the product is 2-8μm, and the...

Embodiment 3

[0040] 1) Put 41g lithium fluoride, 59g lithium carbonate, 118g ferrous fluoride, 255g ferrous oxalate, 370g ammonium dihydrogen phosphate, 3.9g magnesium fluoride, 11g titanium fluoride, 100g sucrose and 780g deionized water in a ball mill Medium mixing for 5 hours;

[0041] 2) drying and ball milling for 3 hours;

[0042] 3) After heating up to 350°C at a rate of 2°C / min in a nitrogen protection furnace, keep the temperature constant for 6 hours;

[0043] 4) cooling to room temperature, ball milling in ball mill for 8 hours;

[0044] 5) At 1500KN / cm 2 Tablets under pressure;

[0045] 6) In the nitrogen protection furnace, the temperature was raised to 900°C at a rate of 3°C / min, and the temperature was kept constant for 12 hours;

[0046] 7) Cool naturally, and ball mill for 3 hours to obtain the multi-component doped spherical lithium iron phosphate positive electrode material of the present invention, and the product is spherical. The average particle size of the prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com